The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

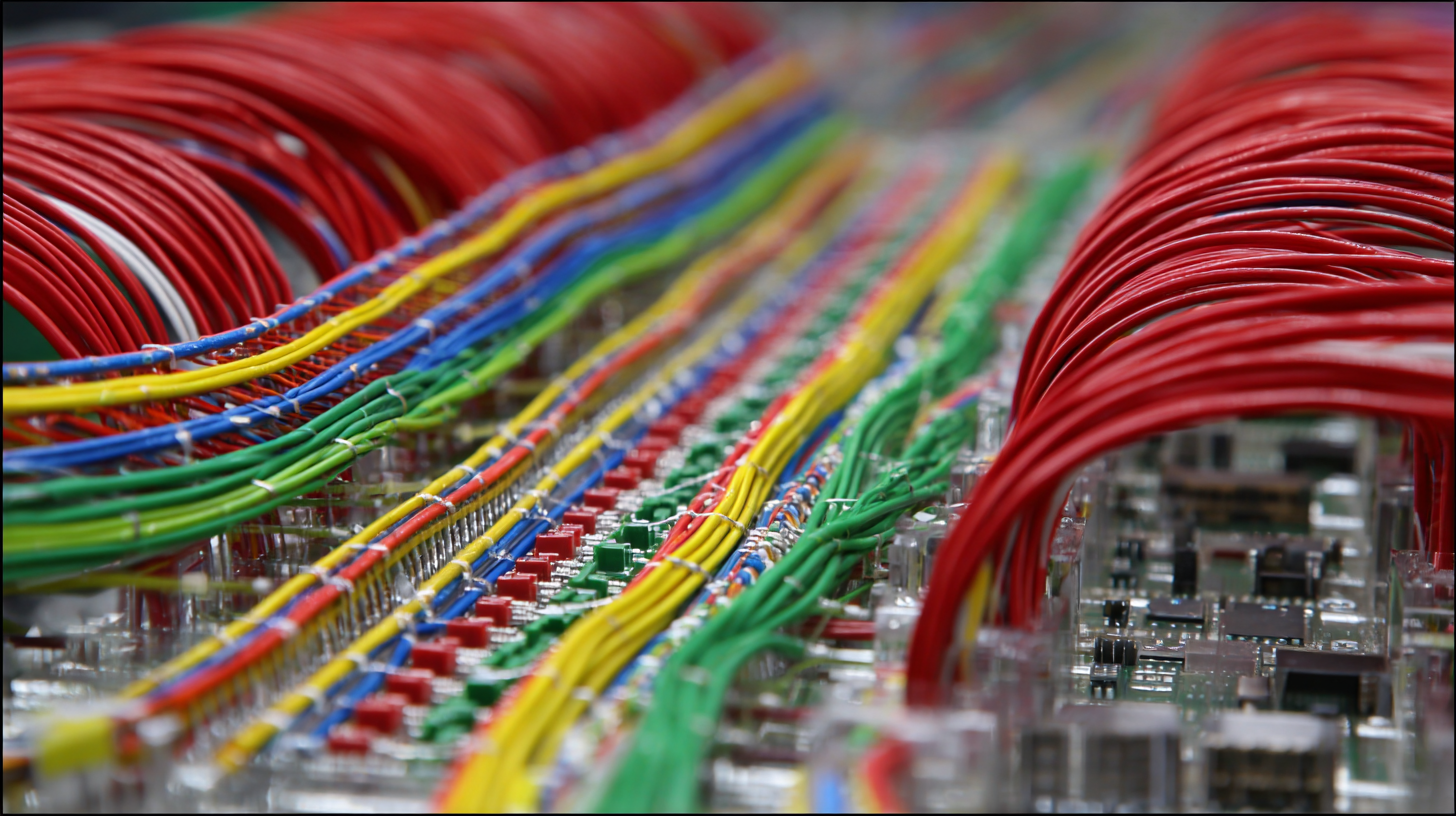

In recent years, the wire harness cable assembly industry has witnessed remarkable growth, driven by advancements in technology and increasing demand across various sectors including automotive, aerospace, and electronics. According to a report by MarketsandMarkets, the global wire harness market is projected to reach USD 75.58 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.8% from 2021. As manufacturers increasingly focus on quality and efficiency, leading companies from China are setting benchmarks in the global market.

The phrase "从中国走向世界,品质赢得全球市场" encapsulates a burgeoning shift where high-quality wire harness cable assembly products are not only meeting local demands but also satisfying international quality standards. This evolution presents significant opportunities for businesses willing to adapt to the changing landscape and harness the potential of innovative manufacturing practices.

Emerging Trends in Wire Harness Cable Assembly for 2023 and Beyond

The wire harness cable assembly industry is experiencing a transformative shift as we move into 2023 and beyond. One of the most significant emerging trends is the integration of smart technologies into wire harness design and production. Manufacturers are increasingly adopting automation and IoT-enabled solutions to enhance efficiency, reliability, and real-time monitoring of assembly processes. This shift not only improves productivity but also ensures higher quality control standards, catering to the rising demands in sectors such as automotive, aerospace, and electronics.

Another notable trend is the emphasis on sustainable practices within the industry. As environmental concerns grow, companies are seeking eco-friendly materials for wire harnesses, such as bioplastics and recycled metals. Additionally, the adoption of circular economy principles is becoming more prevalent, encouraging manufacturers to develop solutions that minimize waste and maximize lifespan. By prioritizing sustainability, wire harness cable assembly companies are aligning themselves with global efforts to foster a cleaner, more responsible manufacturing landscape. These evolving trends indicate a bright future for the industry, driven by innovation and a commitment to sustainable growth.

Key Technologies Shaping the Future of Cable Assembly Industries

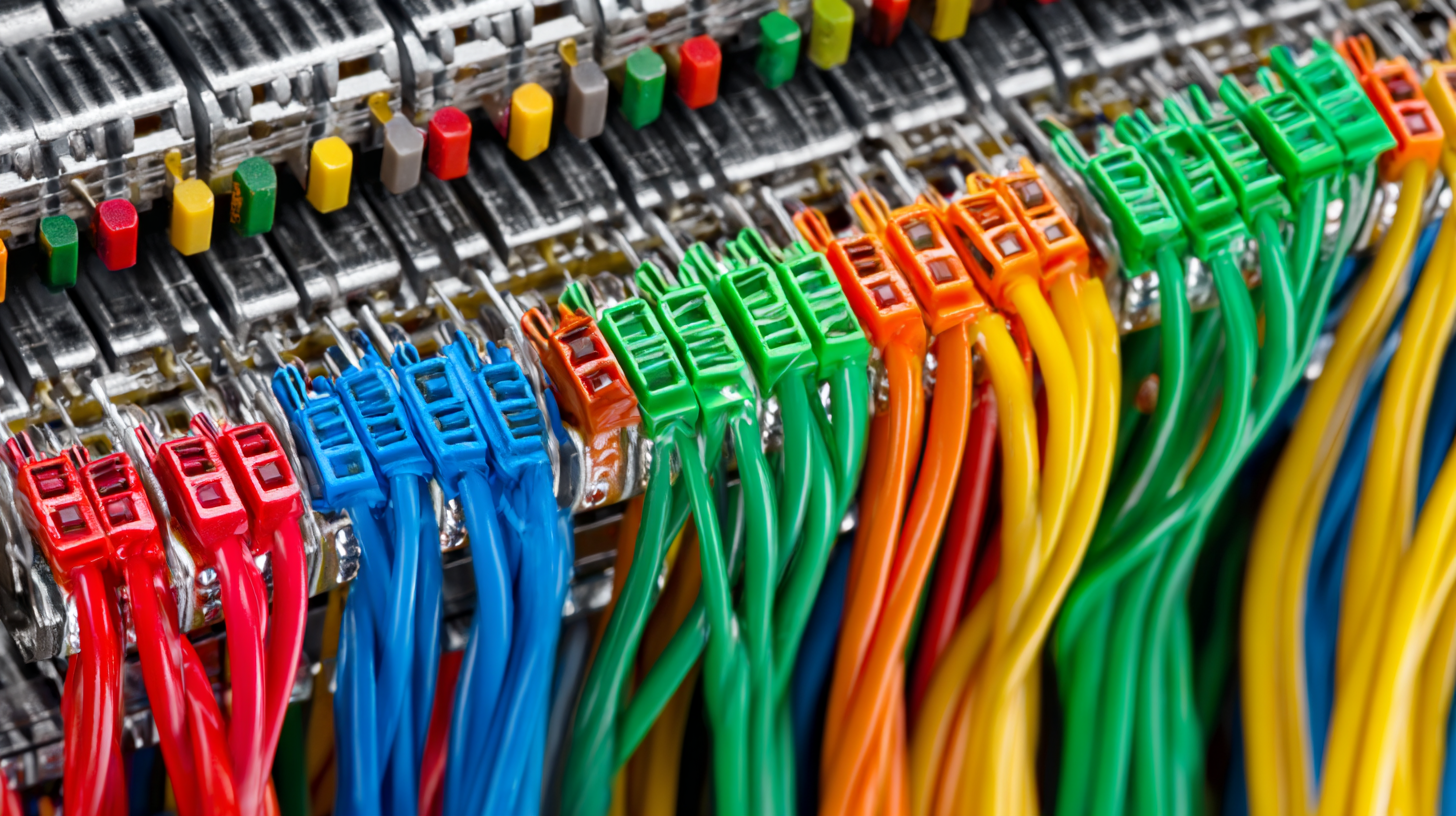

The global market for wire harness cable assemblies is undergoing a significant transformation, driven by key technologies that are reshaping industries. Among these technologies, automation and precision manufacturing stand out as vital components. Advanced robotics and automated systems are increasingly being integrated into the assembly process, enhancing efficiency and reliability. These improvements not only reduce production time but also enhance the overall quality of the wire harnesses, making them more robust for various applications.

Tip: When considering automation, invest in training your workforce to adapt to new technologies. Emphasizing skill development can ensure seamless integration and maximize productivity gains.

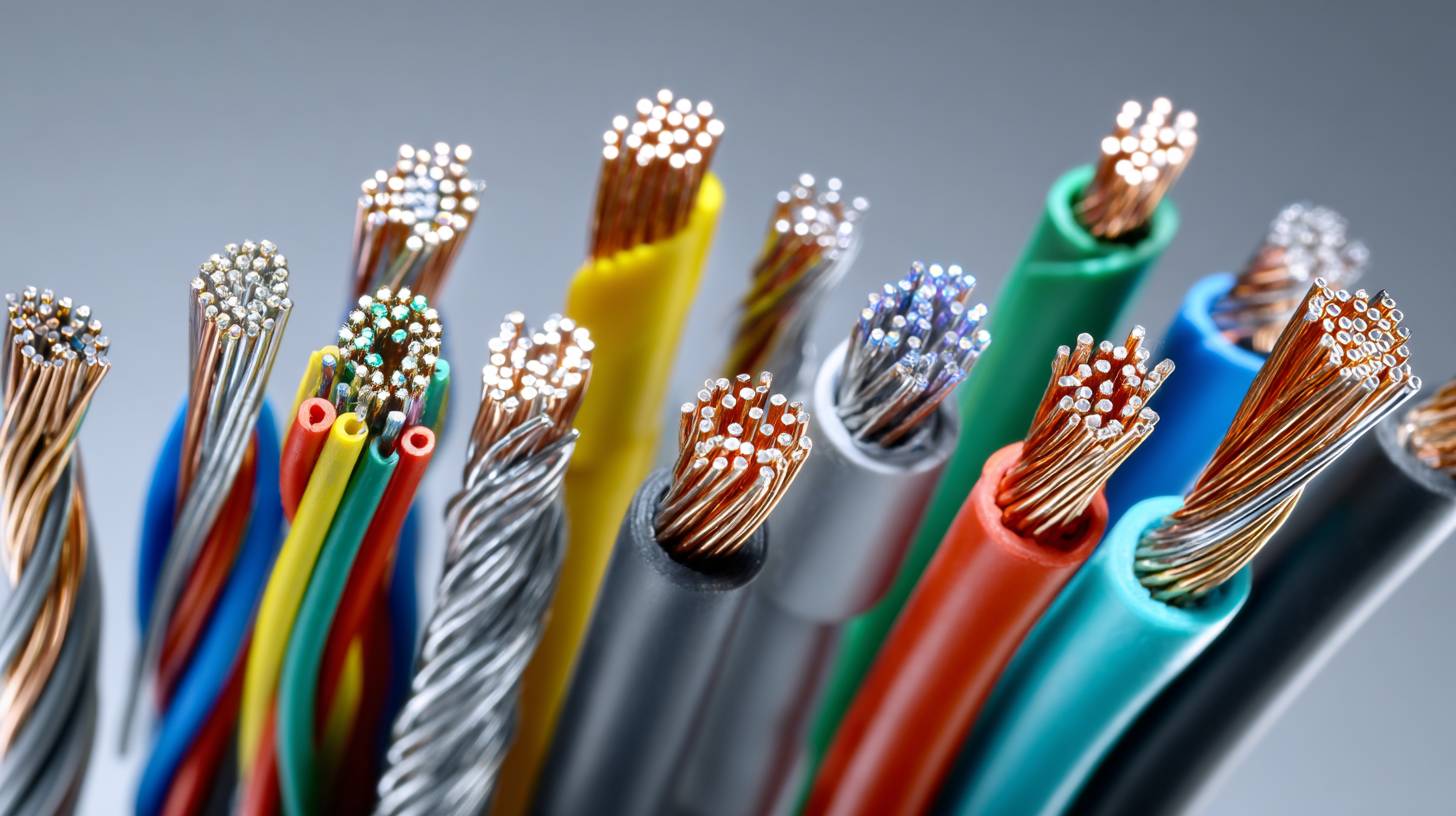

Another crucial technology influencing the future of cable assembly is the rise of more sophisticated materials, such as lighter and more durable composites. These materials contribute to the miniaturization of electronic components, allowing for smaller and more efficient designs. Additionally, the implementation of advanced testing techniques, such as real-time monitoring and predictive analytics, ensures that the products meet stringent quality standards and reduces the likelihood of failures in the field.

Tip: Stay updated on material innovations and consider partnerships with suppliers who offer cutting-edge solutions. This approach will enable you to stay competitive in an ever-evolving market landscape.

Sustainability in Wire Harness Manufacturing: Innovations and Strategies

In the rapidly changing landscape of the global market, sustainability has emerged as a key focus for wire harness manufacturing. Innovations are reshaping the industry, with manufacturers increasingly integrating eco-friendly materials and processes. According to a recent report by the International Wire Harness Manufacturers Association (IWHMA), nearly 45% of companies now prioritize sustainable practices in their operations, reflecting a significant shift towards environmental responsibility.

To enhance sustainability, companies are exploring strategies such as the use of biodegradable insulation materials and reusable packaging. A study by Technavio reveals that the global market for eco-friendly wire harnesses is projected to grow by 23% over the next five years. As consumers demand greener products, manufacturers who adopt innovative materials will not only meet regulatory requirements but also gain a competitive edge.

Tip: Companies looking to improve sustainability in their operations can start by conducting a thorough audit of their supply chain to identify areas for waste reduction and alternative material sourcing.

Tip: Engaging in partnerships with suppliers who prioritize sustainability can lead to shared innovations and cost savings, ensuring a more resilient and environmentally friendly production process.

Global Supply Chain Challenges and Their Impact on Cable Assembly

In the rapidly evolving global market for wire harness cable assembly, supply chain challenges have become more pronounced, impacting not just production timelines but also costs and quality. According to a report by Mordor Intelligence, the global wire harness market is expected to reach $79.38 billion by 2026, growing at a CAGR of 4.5%. However, disruptions like the COVID-19 pandemic and geopolitical tensions have led to shortages of raw materials and components, causing delays in manufacturing processes.

Furthermore, a study by Deloitte highlights that 70% of manufacturers are struggling to secure reliable suppliers due to supply chain disruptions, which is greatly affecting the cable assembly sector. This reliance on a fragile supply chain model necessitates a shift towards more localized sourcing and a diversified supplier base to mitigate risks. In order to remain competitive, companies must adapt their strategies to address these supply chain vulnerabilities and embrace innovative solutions such as automation and smart manufacturing technologies. As the market continues to globalize, navigating these complexities will be essential for success in the wire harness cable assembly industry.

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market - Global Supply Chain Challenges and Their Impact on Cable Assembly

| Region | Market Size (2023) | Expected Growth Rate (2024-2028) | Key Challenges | Impact on Assembly |

|---|---|---|---|---|

| North America | $1.5 Billion | 5% | Supply chain disruptions, labor shortages | Increased costs and lead times |

| Europe | $2 Billion | 6% | Regulatory changes, material shortages | Need for alternative materials and suppliers |

| Asia-Pacific | $3 Billion | 8% | Infrastructure issues, trade tariffs | Potential delays and increased operational costs |

| Latin America | $800 Million | 4% | Political instability, logistical challenges | Impact on production schedules |

| Middle East & Africa | $400 Million | 3% | Market uncertainty, funding issues | Limited growth opportunities |

Skills and Resources Required for Success in the Evolving Market Landscape

As the global market for wire harness cable assembly evolves, companies must adapt by cultivating a diverse set of skills and resources. Technical expertise remains paramount; engineers and technicians must possess a solid understanding of the latest materials, design software, and manufacturing techniques. Familiarity with automation and robotics is increasingly important, as these technologies enhance precision and efficiency in production processes. Organizations should invest in ongoing training to ensure that their workforce remains at the forefront of industry advancements.

In addition to technical skills, businesses operating in this sector must also focus on strategic resource management. Establishing strong supplier relationships can lead to a more reliable sourcing of components, which is critical in a market where component shortages can disrupt operations. Furthermore, embracing sustainability through eco-friendly materials and practices is becoming a competitive advantage, appealing to environmentally conscious consumers. By fostering a culture of innovation and adaptability, wire harness cable assembly providers can thrive in an ever-changing market landscape.

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

This chart illustrates the projected growth areas in the wire harness cable assembly market over the next five years, focusing on various sectors and their expected annual growth rates.