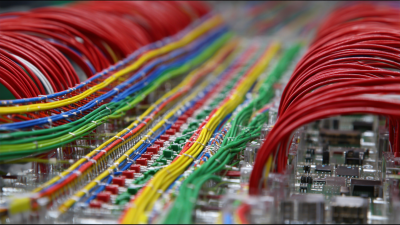

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards

The wire harness cable industry is undergoing a significant transformation, driven by innovations that enhance efficiency, safety, and sustainability across various sectors. According to a recent report by MarketsandMarkets, the global wire harness market is projected to reach $75.15 billion by 2025, growing at a CAGR of 5.65% from 2020 to 2025.

This growth is fueled by increasing demand in automotive, aerospace, and telecommunications, where the complexity of systems continues to rise.

As industries adopt advanced technologies such as automation, IoT, and electric vehicles, the wire harness cable solutions are being refined to meet stringent standards.

This blog explores seven cutting-edge innovations in wire harness technology that are not only revolutionizing industry practices but also setting new benchmarks for performance and reliability.

This growth is fueled by increasing demand in automotive, aerospace, and telecommunications, where the complexity of systems continues to rise.

As industries adopt advanced technologies such as automation, IoT, and electric vehicles, the wire harness cable solutions are being refined to meet stringent standards.

This blog explores seven cutting-edge innovations in wire harness technology that are not only revolutionizing industry practices but also setting new benchmarks for performance and reliability.

Key Innovations in Wire Harness Technology Transforming Production Efficiency

The wire harness industry is experiencing a significant transformation, largely driven by innovative technologies that enhance production efficiency. With the growing complexity of automotive systems and the rise of industrial automation, manufacturers are adopting advanced wire harness solutions that streamline assembly processes and reduce error rates. The integration of AI and digital tools into wire harness production is not only optimizing workflows but also fostering a shift towards more sustainable practices. By leveraging data-driven decision-making, companies can now analyze and predict production outcomes, thus making informed adjustments to improve efficiency.

Moreover, the increasing emphasis on sustainable materials, such as bioplastics, is reshaping the wire harness market. As concerns about plastic pollution become more prominent, the development of alternatives like polyhydroxyalkanoates (PHAs) is paving the way for greener production methods. This shift aligns with broader initiatives supported by substantial funding aimed at integrating AI across industries, ultimately revolutionizing how production is approached. As manufacturers embrace these innovations, the wire harness sector is making strides toward a more efficient, sustainable, and flexible future.

Advanced Materials: Enhancing Durability and Performance of Wire Harnesses

In the rapidly evolving landscape of the wire harness industry, advanced materials are paving the way for enhanced durability and performance. According to a recent report by Research and Markets, the global wire harness market is projected to grow from USD 48.57 billion in 2020 to USD 83.08 billion by 2027, reflecting a CAGR of 8.13%. This growth is significantly driven by innovations in materials such as heat-resistant polymers and high-strength composites, which not only improve the endurance of wire harnesses but also reduce weight, contributing to greater efficiency in automotive and aerospace applications.

Moreover, the adoption of thermoplastic elastomers (TPEs) is revolutionizing insulation options, providing superior resistance to chemicals and extreme temperatures. A report from Mordor Intelligence highlights that the use of TPEs in wire harnesses can improve flexibility and lifespan by up to 20% compared to traditional materials. This increase in performance is crucial as industries push towards more sustainable practices, with lightweight materials leading to lower fuel consumption and emissions. As the demand for reliable and high-performance wire harnesses continues to rise, these advanced materials are becoming indispensable, setting new benchmarks for industry standards.

Smart Wiring Solutions: The Role of IoT in Modern Cable Design

The integration of the Internet of Things (IoT) into modern cable design is transforming the landscape of wire harness innovations. Smart wiring solutions allow for real-time data collection and monitoring, significantly enhancing operational efficiency across various industries. According to a report from the International Data Corporation (IDC), IoT-connected devices are expected to reach 41.6 billion by 2025, underscoring the critical role of advanced cable systems in supporting these technologies. The ability to seamlessly integrate sensors and communication modules directly into wire harnesses provides manufacturers with unprecedented control over their operations.

Moreover, smart wiring solutions are facilitating predictive maintenance, which can lead to substantial cost savings. A study by Deloitte indicates that predictive maintenance can reduce maintenance costs by 25% to 30% while decreasing equipment downtime by approximately 50%. By incorporating IoT capabilities, wire harnesses not only optimize performance but also enable proactive responses to potential failures, extending the lifespan of critical machinery. As industries continue to evolve, the demand for innovative cable designs that accommodate IoT functionalities is set to surge, redefining standards and pushing boundaries in efficiency and reliability.

Eco-Friendly Wire Harness Developments: Sustainable Practices for the Future

The push for eco-friendly practices in the manufacturing industry has led to innovative developments in wire harness technology. As sustainability becomes a priority, manufacturers are increasingly focused on utilizing recyclable and biodegradable materials in their wire harness designs. This shift not only reduces environmental impact but also meets the growing demand for greener solutions from consumers and industries alike. Innovative materials, such as bio-based plastics and recycled metals, are gaining traction, paving the way for a more sustainable future.

In addition to material advancements, production processes are also being re-evaluated. Techniques like modular design and smart manufacturing are emerging to minimize waste and enhance efficiency. By adopting strategies that prioritize environmental considerations, companies are not only complying with regulations but also setting new industry standards. These eco-friendly innovations in wire harness development reflect a broader commitment to sustainability, positioning the industry for long-term success while contributing positively to the planet.

In addition to material advancements, production processes are also being re-evaluated. Techniques like modular design and smart manufacturing are emerging to minimize waste and enhance efficiency. By adopting strategies that prioritize environmental considerations, companies are not only complying with regulations but also setting new industry standards. These eco-friendly innovations in wire harness development reflect a broader commitment to sustainability, positioning the industry for long-term success while contributing positively to the planet.

Cutting-Edge Manufacturing Techniques Redefining Wire Harness Standards

In the rapidly evolving world of wire harness manufacturing, cutting-edge techniques are setting new industry standards. Innovations in materials and technology are enhancing the performance and efficiency of wire harnesses. For instance, the adoption of lightweight materials is not only reducing the overall weight of automotive components but also improving their resistance to environmental factors, ultimately leading to greater longevity and reliability in vehicles. Manufacturers are embracing automation and advanced manufacturing processes, allowing for higher precision and scalability in production.

The future of the wire harness industry looks promising, especially with the significant growth projected in markets like Mexico. With the automotive wiring harness market in Mexico expected to soar from USD 684.62 million in 2024 to USD 1054.69 million by 2035, it highlights the increasing demand and importance of sophisticated wire harness solutions. This growth signals a shift towards more advanced manufacturing techniques that prioritize quality, innovation, and sustainability, ensuring that wire harnesses continue to meet the needs of modern automotive applications while driving industry standards forward.

Related Posts

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

-

7 Best Practices for Effective Harness Cable Assembly Sourcing Globally

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

Leading Global Manufacturing Facilities in Wire Harness Production Equipment