What is Cable Wire Harness Assembly and Its Importance in 2026?

The growing reliance on technology across multiple sectors has highlighted the crucial role of cable wire harness assembly. According to industry reports, the global market for cable wire harness assemblies is projected to reach $100 billion by 2026, driven by the increasing demand in automotive, aerospace, and consumer electronics. This growth underlines not only the importance but also the complexity of cable harness systems in ensuring device functionality.

Cable wire harness assembly consists of bundled wires that transmit power and data. As devices become more sophisticated, the design of these assemblies must evolve. Innovative materials and techniques are required to enhance durability and performance. However, this progression does not come without challenges. Quality control issues and production inefficiencies can impact overall effectiveness. It is vital for manufacturers to adapt quickly.

In 2026, as automation and connectivity continue to advance, efficient cable wire harness assembly will be more important than ever. With industry demand on the rise, ensuring reliability and performance must remain a priority. Addressing these concerns head-on can secure a competitive advantage. The future of cable wire harness assembly lies not only in its growth but also in continuous improvement and reflection on existing practices.

Understanding Cable Wire Harness Assembly: Definition and Components

Cable wire harness assembly plays a crucial role in various electronic systems. It consists of multiple wires bundled together, often covered with an outer sheath. This assembly helps manage cables efficiently, reducing clutter in electronic devices. A typical harness includes connectors, terminals, and various types of insulation. Each component serves a specific function, ensuring the entire system operates smoothly.

In the assembly process, wires are cut to specific lengths and attached to connectors. The arrangement of wires is essential for optimal performance. Poorly organized harnesses can lead to faults and increased maintenance. The use of heat shrink tubing is common. It protects the wires while providing insulation. Each step in the assembly must be precise, yet many overlook the importance of quality control.

Assembly techniques may vary, leading to differences in reliability. Some may rush the process, compromising quality. Attention to detail is vital. This focus can prevent future issues and improve performance. In 2026, as technology advances, the demand for efficient cable wire harness assemblies will likely grow. Understanding these components could enhance design strategies and ensure long-term success.

What is Cable Wire Harness Assembly and Its Importance in 2026?

| Component | Material | Function | Importance in 2026 |

|---|---|---|---|

| Wires | Copper or Aluminum | Conduct electricity | Essential for power distribution |

| Connectors | Plastic and Metal | Join multiple wires | Increase system reliability |

| Insulation | PVC or XLPE | Prevent short circuits | Enhance safety standards |

| Moldings | Plastic or Rubber | Protect connections | Key for durability in harsh environments |

| Heat Shrink Tubing | Polyolefin | Provide insulation and strain relief | Critical for system longevity |

The Manufacturing Process of Cable Wire Harness Assembly

Cable wire harness assembly is a critical part of modern manufacturing. This process involves grouping electrical wires, connectors, and terminals into a cohesive unit. The key here is precision. Poorly assembled harnesses can lead to failures in electronic devices. This aspect can't be overlooked.

During manufacturing, each wire must be carefully cut to specific lengths. Proper insulation is crucial to prevent short circuits. Connectors need to be crimped tightly, ensuring a strong bond. Sometimes, mistakes happen, such as incorrect measurements. These errors can delay production and impact quality.

Tips for a smooth assembly process: Always double-check measurements before cutting wires. Use quality materials for insulation and connectors. Training staff on best practices can minimize errors. Learning from past mistakes improves the overall process. Regular audits can catch issues early, preventing further complications. Time invested in quality control pays off in the long run.

Applications of Cable Wire Harness in Various Industries

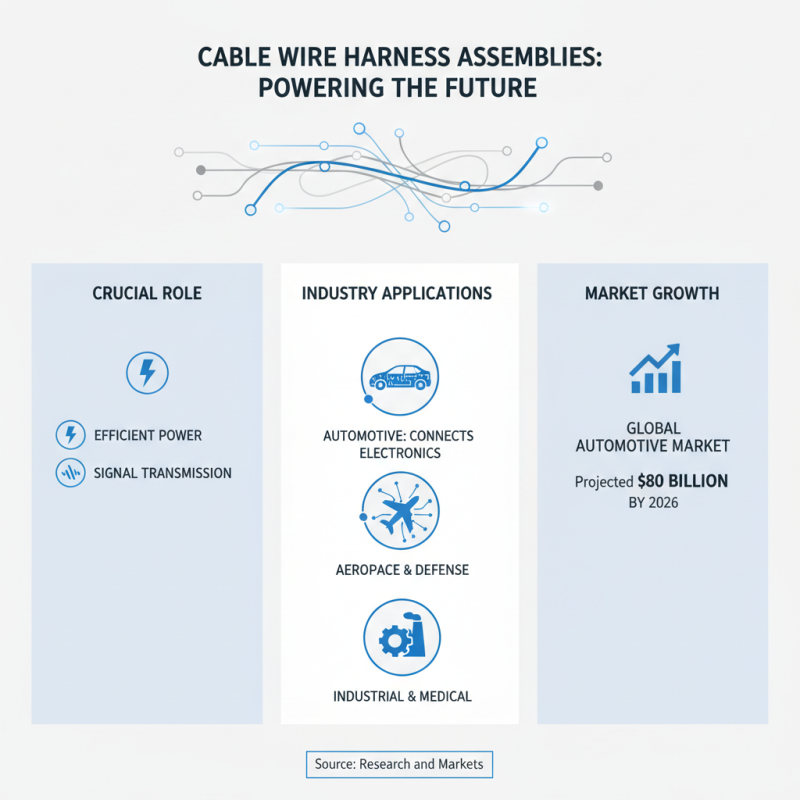

Cable wire harness assemblies play a crucial role across various industries, ensuring efficient power and signal transmission. In the automotive sector, for example, these assemblies are essential for connecting numerous electronic components. A report from Research and Markets projects that the global automotive wire harness market will reach $80 billion by 2026, highlighting its growing importance.

In the aerospace industry, wire harnesses are vital for safety and performance. They connect flight control systems and avionics equipment. According to a study by MarketsandMarkets, the aerospace wire harness market is expected to expand significantly, driven by increasing aircraft orders and technological advancements. This underscores the necessity of reliable wire harness assemblies in critical applications.

Tips: Prioritize quality materials for wire harnesses. This choice directly affects durability and efficiency. Ensure that your assembly process is well-documented to avoid errors and enhance safety. Constantly evaluate and refine your designs based on real-world feedback. This practice can help identify areas for improvement and innovation, which is key in fast-paced industries.

Significance of Cable Wire Harness in Modern Technology by 2026

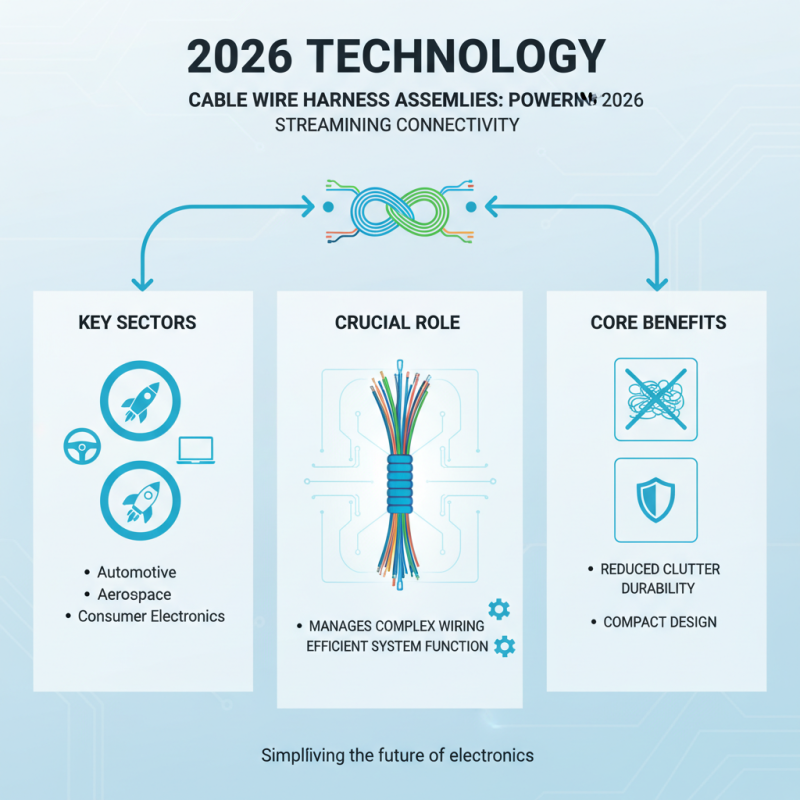

In 2026, cable wire harness assemblies play a crucial role in modern technology. They streamline the connectivity of various electronic components. These assemblies are used in automotive, aerospace, and consumer electronics. The significance lies in their ability to manage complex wiring systems efficiently. Each harness reduces clutter and improves durability. This compact design ensures systems function smoothly.

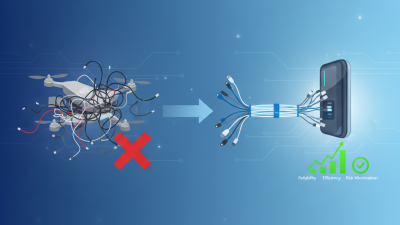

Despite their importance, challenges remain. Poorly designed harnesses can lead to failures. These failures may result in costly repairs and safety risks. Manufacturers must focus on quality and precision. Shortcuts in design can have lasting impacts. The need for better materials and innovative designs is pressing. Sustainability in production methods also requires attention. As technology evolves, so do the demands on cable wire harnesses. Effective solutions must be prioritized.

Future Trends and Innovations in Cable Wire Harness Assembly

The cable wire harness assembly is evolving rapidly. In 2026, its role in various industries will expand significantly. The demand for customized solutions is on the rise. Manufacturers are focusing on more efficient designs. These innovations will reduce assembly time and costs.

Future trends include the integration of smart technologies. Smart wire harnesses will monitor performance in real-time. This capability will help in maintenance and troubleshooting. Additionally, automation in assembly processes is gaining traction. Robotic systems will enhance precision and reduce human errors. However, adaptation to these technologies can be challenging. Not all companies may keep pace with these changes.

Sustainability is another key focus for the future. Eco-friendly materials are becoming more popular. However, sourcing these materials can be complex. Companies will need to balance cost and environmental impact. As the industry moves forward, collaboration among stakeholders will be essential. There will be a need for continued innovation and adaptability. The cable wire harness assembly sector must not only embrace new technologies, but also reflect on its practices to ensure long-term success.

Trends in Cable Wire Harness Assembly (2026)

This bar chart illustrates the importance of various trends in cable wire harness assembly as we approach 2026. Automation and miniaturization are predicted to be the most critical factors, with sustainability also playing a significant role in shaping future innovations.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

2025 Guide on How to Choose the Right Harness Cable Assembly for Your Needs

-

Top 10 Harness Assembly Solutions: Boosting Efficiency with Industry-Leading Data and Insights

-

Top 10 Essential Tips for Choosing Wire Harnesses for Your Projects

-

Why Cable Wire Harness Assembly is Crucial for Your Product Success