How to Choose the Right Wire Harness Wire for Your Project

When embarking on an electrical project, selecting the appropriate wire harness wire is critical to ensure not only functionality but also safety and durability. According to John Smith, a leading expert in the wire harness industry with over 20 years of experience, "The right wire harness wire can make all the difference in the performance and reliability of your system." This highlights the importance of understanding the specific requirements of your project and the various types of wire harness wires available.

Different projects come with varying demands based on their complexity, environment, and application. For instance, automotive wiring requires resilient wire harness wires that can withstand high temperatures and vibrations, while industrial applications might prioritize corrosion resistance and signal integrity. In this landscape, making informed choices based on expert insights and understanding the materials, insulation types, and gauge specifications can ultimately lead to a successful outcome.

As you navigate the myriad options, it's essential to consider factors such as current carrying capacity, voltage ratings, and environmental conditions. By doing so, you not only enhance the longevity of your project but also ensure that it operates at peak performance. Choosing the right wire harness wire is not just a technical decision—it's an investment in the overall success of your electrical application.

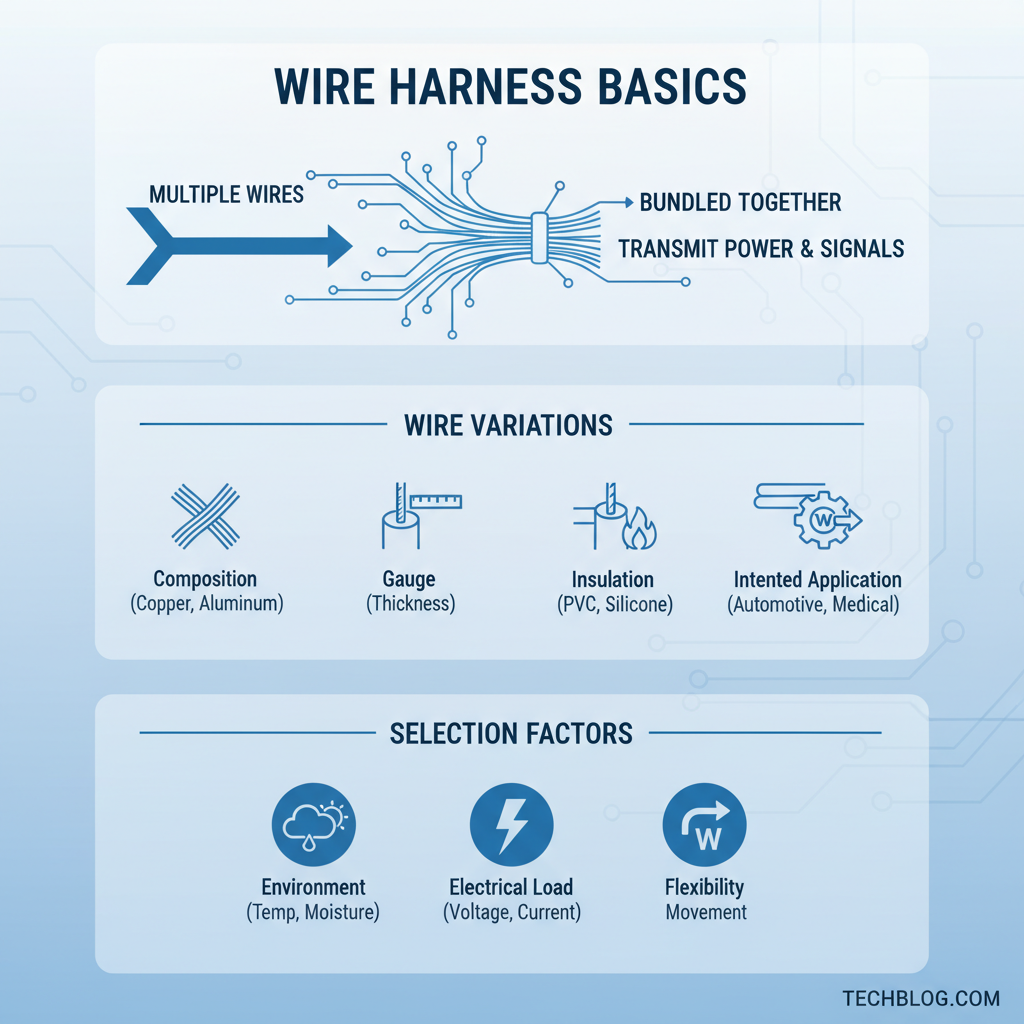

Understanding the Basics of Wire Harness Wires

When embarking on a project involving wire harnesses, understanding the basics of wire harness wires is essential. Wire harnesses consist of multiple wires bundled together to transmit electrical power and signals efficiently. The wires used in these harnesses can vary significantly in terms of composition, gauge, insulation, and intended application. Selecting the right wire involves considering factors such as the environment in which the wire will be used, the electrical load requirements, and the overall flexibility needed for the application.

One of the key considerations when choosing wire harness wires is the wire gauge, which affects the maximum current that can safely pass through without overheating. Thicker wires (lower gauge numbers) can handle higher currents but may be less flexible, while thinner wires (higher gauge numbers) are more flexible but may not support heavy loads. Additionally, the type of insulation used is crucial as it determines the wire's durability against various environmental factors, including temperature, moisture, and chemicals. Understanding these basics will help ensure that your wire harness functions correctly and reliably throughout its intended lifespan.

Identifying the Key Specifications for Your Project

When selecting the right wire harness wire for your project, understanding key specifications is crucial. Important factors include wire gauge, insulation type, temperature ratings, and current-carrying capacity. For instance, according to the National Electrical Code (NEC), using the correct gauge is essential to prevent overheating; a wire that is too thin for the intended load can pose serious safety hazards. Wire gauge is measured according to the American Wire Gauge (AWG) scale, where a lower number indicates a thicker wire, which can carry more current.

Another critical specification is the type of insulation. The choice of insulation material—such as PVC, Teflon, or rubber—impacts both durability and environmental resistance. Research from the Wire and Cable Manufacturers Alliance (WCMA) indicates that choosing the right insulation can enhance a wire's resilience to temperature extremes and chemical exposure by up to 30%. Additionally, understanding the temperature rating of the wire is essential; for example, a wire rated for 90°C may not be suitable for high-heat applications, leading to premature failure. By carefully considering these specifications, you can ensure optimal performance and longevity for your wire harness project.

How to Choose the Right Wire Harness Wire for Your Project - Identifying the Key Specifications for Your Project

| Specification | Description | Importance |

|---|---|---|

| Wire Gauge | The thickness of the wire, typically measured in AWG (American Wire Gauge). | Determines current-carrying capacity and flexibility. |

| Insulation Type | Material used to insulate the wire, such as PVC or XLPE. | Affects durability, temperature rating, and resistance to chemicals. |

| Temperature Rating | The maximum temperature the wire can withstand. | Crucial for safety and performance in varying conditions. |

| Voltage Rating | The maximum voltage the wire can handle without breakdown. | Ensures compatibility with the electrical system. |

| Stranding | The number of strands used in a wire. | Increases flexibility and resistance to vibration. |

| Conductor Material | Material used for the conductor, typically copper or aluminum. | Impacts conductivity, cost, and overall performance. |

| Application | Intended use case, such as automotive, industrial, or consumer electronics. | Influences all other specifications based on environmental demands. |

Evaluating Different Types of Wire Materials

When evaluating different types of wire materials for your wire harness project, it's crucial to consider factors such as conductivity, flexibility, and environmental resistance. Common materials include copper, aluminum, and specialized alloys.

Copper is often favored for its excellent electrical conductivity and durability, making it ideal for applications requiring high performance. On the other hand, aluminum is lighter and more cost-effective, though it has lower conductivity. For harsh environments, look for wires that are coated or insulated with specialized materials to provide additional protection.

Tips:

- Assess the specific electrical requirements of your project to determine the wire gauge and material needed.

- Consider the installation conditions, such as temperature and moisture, which can affect wire performance and longevity.

- Always verify the certification of wire materials, especially if used in critical applications, to ensure compliance with industry standards.

Choosing the right wire material can make a significant difference in the efficiency and reliability of your wire harness. By evaluating these factors carefully, you can ensure that your project is set up for success.

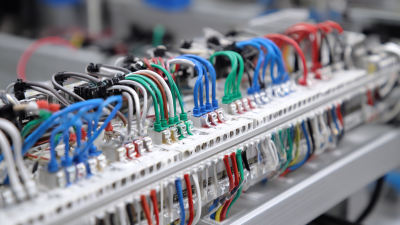

Assessing Insulation and Strain Relief Options

When selecting the right wire harness wire for your project, assessing insulation and strain relief options is crucial to ensure durability and performance. Insulation materials, such as PVC, XLPE, or Teflon, play a vital role in protecting the inner wire from environmental factors and electrical interference. Depending on your project's requirements, consider the temperature range, abrasion resistance, and chemical exposure when choosing the insulation type.

For strain relief, it's essential to choose components that minimize stress on the wire connections. Strain relief can be achieved through various methods, such as using heat shrink tubing, grommets, or molded connectors. These options help prevent cable fatigue and potential damage over time.

Tips: When selecting insulation, always evaluate the specific conditions the wire will face, including humidity and exposure to chemicals. For strain relief, ensure that your chosen solution allows some flexibility, reducing the risk of breakage during installation or movement. Prioritize quality materials to enhance long-term reliability and safety in your wire harness design.

Choosing the Appropriate Gauge for Your Wiring Needs

When choosing the right wire harness wire for your project, selecting the appropriate gauge is crucial. The gauge refers to the thickness of the wire, which directly impacts the wire's capacity to carry electric current without overheating. A thicker wire (lower gauge number) can carry more current, while a thinner wire (higher gauge number) carries less. It’s important to assess the electrical requirements of your project to determine the best gauge for optimal performance and safety.

**Tips:** Always refer to the American Wire Gauge (AWG) standard when selecting wire sizes. If you’re uncertain about the current load, opt for a thicker wire for added safety. Additionally, consider factors such as the length of the wire and environmental conditions, as these can affect current flow and the risk of voltage drop.

Another important point to keep in mind is the insulation type that corresponds with your chosen gauge. Different insulation materials can withstand varying temperatures and chemical exposures, impacting the overall longevity and safety of your wiring project. Ensure that the wire harness wire you choose complements the specific needs of your application for a reliable connection.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing

-

Transforming Electronics with Custom Wire Harness and Cable Assembly Solutions

-

2025 Top 10 Cable and Wire Harness Innovations Driving Industry Growth