How to Choose the Best Geomembrane Welding Machine?

Choosing the right geomembrane welding machine is crucial for successful projects. These machines ensure strong and reliable seams in various applications. Poor quality machines can lead to failures and costly repairs.

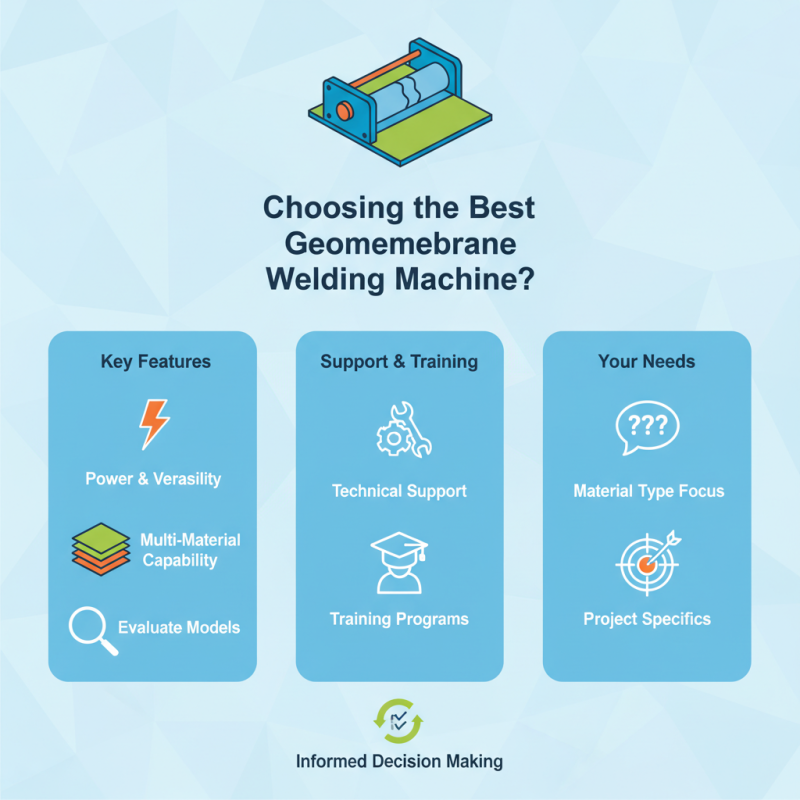

When selecting a geomembrane welding machine, consider its different features. Power and versatility are key factors. A machine that can handle multiple materials is often more beneficial. Take time to evaluate various models. It’s important not to rush this decision.

Users often overlook the significance of machine support and training. A machine with good technical support may save time and money later. Additionally, reflect on your actual needs. What materials will you work with most? This should guide your choice.

Factors to Consider When Selecting a Geomembrane Welding Machine

When selecting a geomembrane welding machine, several factors require careful consideration. The thickness of the geomembrane material is crucial. Different welding machines handle varying thicknesses effectively. Machines designed for high-density polyethylene (HDPE) materials often work best for thicker sheets. According to industry data, machines suitable for 60 mil and above sheets can enhance production efficiency.

The type of welding method is another important element. Hot wedge welding and extrusion welding are common techniques. Hot wedge welding is suitable for speed and efficiency. Meanwhile, extrusion welding can be better for extending joints. Assess your project's specific needs before deciding.

Tips: Always verify the machine's temperature range. This affects the quality of the weld. Look for machines that allow adjustments for different materials. This flexibility can be vital for varied projects. Finally, consider usability and weight; it impacts mobility on-site.

Choosing the right machine is not just about specifications. It requires balancing performance, durability, and project demands. Sometimes, machines may not perform as expected under real-world conditions. Always conduct thorough testing before full deployment to avoid future complications.

Types of Geomembrane Welding Technologies Available

When selecting a geomembrane welding machine, understanding the different welding technologies is crucial. Hot wedge welding is one of the most widely used methods. It involves heating a wedge-shaped element that melts the geomembrane edges. This method is efficient and provides strong welds. However, it requires skilled operators to ensure quality. The setup can be tricky due to varying material thicknesses.

Another popular technique is extrusion welding. This method uses a filler rod that melts along the seam, creating a solid bond. It is versatile and ideal for repairs. However, it may not always achieve the same strength as hot wedge welding. Operators need to be mindful of the extrusion speed to avoid defects.

Finally, there is ultrasonic welding. This technology uses high-frequency vibrations to bond materials. It is valuable for thin geomembranes where traditional methods may struggle. Yet, its effectiveness can vary with different materials. Each method has its pros and cons. It is essential to evaluate them based on specific project needs and operator skills.

How to Choose the Best Geomembrane Welding Machine?

| Welding Technology | Suitable Material | Welding Speed | Power Source | Application Area |

|---|---|---|---|---|

| Hot Wedge Welding | HDPE, LLDPE | 0.5 - 10 m/min | Electric | Landfills, ponds |

| Infrared Welding | PVC, EVA | 1 - 8 m/min | Electric | Aquaculture, liners |

| Electroweld Welding | HDPE | Variable | Electric | Biogas, aquaculture |

| Mechanical Welding | PP, PVC | 1 - 5 m/min | Manual or Electric | General construction |

Key Features to Look for in a Welding Machine

When selecting a geomembrane welding machine, focus on its key features. A reliable machine needs durable components. Check its heat control capabilities. Look for models that offer adjustable temperature settings. This allows for greater versatility during projects.

Tips: Always test the machine on scrap materials first. This practice minimizes waste and ensures optimal settings.

Welding power is another critical aspect. A machine with sufficient wattage will perform better in various conditions. Inspect the welding speed options too. Faster machines can save significant time, but they should not compromise quality.

Be aware of portability. A lightweight machine is easier to transport. However, it should still be robust and not fragile. Some machines might seem too heavy but are worth the effort due to enhanced stability. Remember, balance is key.

Budgeting for Geomembrane Welding Equipment

Budgeting for geomembrane welding equipment can be challenging. Start by determining your project requirements. Consider the size and complexity of your tasks. Larger installations need more robust machines. However, smaller jobs can often be handled with simpler models. Price ranges can vary widely. Make sure to create a realistic budget that reflects your needs.

Look at the total cost of ownership, not just the initial purchase price. Maintenance, repairs, and potential training costs add up. Sometimes, spending less at first leads to higher costs later. Research warranty options and after-sales support. These can be as important as the equipment itself.

Remember to factor in flexibility for future projects. The equipment should grow with your needs. It’s wise to consult with experienced colleagues before making final choices. They can share insights from their own experiences. Budgeting is not just about numbers; it’s about making informed decisions that benefit your operations long-term.

Budgeting for Geomembrane Welding Equipment

This bar chart represents the estimated costs of various geomembrane welding machines. It aids in budgeting considerations for procurement of equipment based on financial planning and project needs.

Maintenance and Support for Geomembrane Welding Machines

Maintenance is crucial for geomembrane welding machines. Regular checks can prevent unexpected downtime. Ensure all components are functioning well. Keep a clean workspace to avoid contamination. Dirt and debris may compromise weld quality.

Consider following these tips for optimal care. Inspect the welding nozzle often. A clogged nozzle will lead to inconsistent welding. Replace worn-out parts immediately. Proactive measures save costs and enhance performance.

Provide support and training for operators. Well-trained staff will minimize mistakes. Misuse can lead to equipment damage or poor welds. Schedule routine training sessions to keep skills sharp. Regularly review best practices to ensure everyone is informed.