How to Choose the Right Chemical Raw Materials Manufacturer?

Choosing the right chemical raw materials manufacturer is crucial for any business. The quality and reliability of these materials can directly impact product performance and safety. Experts emphasize the importance of this decision. Dr. Sarah Thompson, an industry leader, states, "Choosing a chemical raw materials manufacturer defines the success of your production."

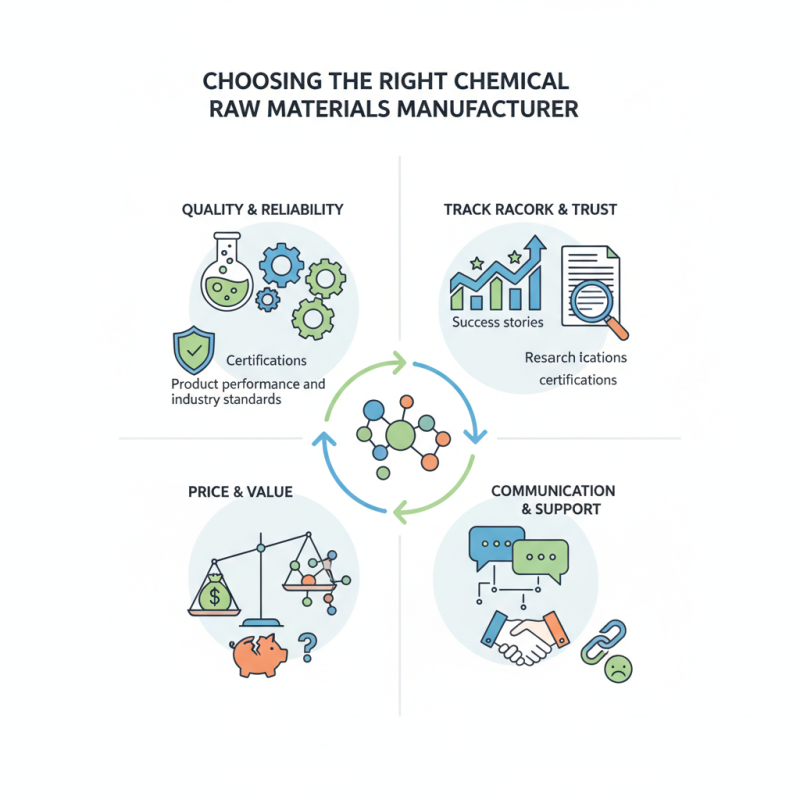

When evaluating manufacturers, focus on their track record. Look for certifications and industry standards. Reliable suppliers often share their success stories. However, it is easy to overlook essential details. Small lapses can lead to significant problems later. Consider both price and quality. The cheapest option might not always be the best choice.

Furthermore, communication is vital. A manufacturer who listens to your needs demonstrates their commitment. Yet, not every company meets these expectations. Some may lack proper support or responsiveness. Assessing potential partners requires discernment. Choosing wisely can foster long-term success.

Understanding the Importance of Raw Material Quality in Chemical Manufacturing

In chemical manufacturing, the quality of raw materials is paramount. Studies show that up to 70% of production issues arise from low-quality inputs. Poor raw materials can lead to significant defects, increased costs, and loss of customer trust. Manufacturers need to prioritize suppliers who adhere to strict quality standards. This is not just an option; it’s a necessity in today's competitive market.

Tips: Always verify supplier certifications. This ensures that the raw materials meet industry standards. Regular audits can help maintain quality control. The right manufacturer can provide samples for testing, allowing companies to assess quality before committing.

Choosing a raw materials manufacturer can be challenging. The landscape is vast and varied. Some companies may seem perfect on paper but fall short in practice. Inconsistent quality can result in production downtime. Manufacturers must analyze the supplier's production processes and track record. Relying solely on price can be deceptive. Often, the cheapest materials compromise quality.

Tips: Conduct thorough research into potential suppliers. Look for testimonials and case studies. Engaging with industry peers can provide valuable insights into supplier reliability. Always keep a buffer stock to mitigate risks from supplier inconsistencies.

Importance of Raw Material Quality in Chemical Manufacturing

Key Factors to Evaluate When Selecting a Chemical Raw Materials Supplier

Choosing the right chemical raw materials manufacturer requires a careful evaluation of several key factors. Quality consistency is paramount. A reliable supplier should maintain strict quality control measures. According to industry reports, 35% of manufacturing issues stem from poor raw material quality. Inspecting certificates and conducting audits can help ensure high standards.

Cost-effectiveness is another critical factor. While price is important, it's essential to consider total cost of ownership. A cheaper supplier may compromise on quality, leading to increased operational costs. The industry standard suggests that companies should factor in potential losses due to inferior materials when evaluating suppliers. This can save headaches down the road.

Communication and support, often overlooked, can make a significant difference. A good supplier should offer responsive customer service. Delays and misunderstandings can disrupt your production. It's vital to establish clear lines of communication. When evaluating potential partners, inquire about their support capabilities.

Tips:

- Request sample materials before making a decision.

- Check for customer reviews and case studies.

- Don't rush; thorough research pays off.

Analyzing Supplier Certifications and Industry Standards for Chemical Manufacturing

When choosing a chemical raw materials manufacturer, certifications matter. Suppliers should hold relevant certifications that align with industry standards. Look for ISO certifications, which indicate a commitment to quality and safety. These certifications help ensure that the materials meet specific regulations.

Industry standards vary by sector. Some materials require compliance with environmental regulations, while others must adhere to safety guidelines. This complexity can be overwhelming. Sometimes, companies may claim compliance without proper backing. It's essential to verify these claims. Request documentation and check for audits.

Not all manufacturers will have all certifications. Some may excel in safety but lack environmental credentials. This can lead to gaps in compliance. Take the time to assess what standards are crucial for your needs. A deep understanding of these requirements helps in making informed decisions. Don't overlook the importance of choosing a manufacturer who values transparency.

Assessing Supply Chain Reliability and Delivery Timeliness of Manufacturers

When choosing a chemical raw materials manufacturer, evaluating supply chain reliability is crucial. A reliable supplier ensures that materials arrive on time and meet quality standards. Check their history of delivery performance. Reliable manufacturers often have established relationships with logistics providers. They also maintain clear communication about potential delays.

Delivery timeliness is as important as reliability. Inconsistent delivery schedules can disrupt production lines. Ask for references to assess a manufacturer’s track record. Industry peers can provide insight into their experiences with delivery timelines. Look for warning signs, such as frequent delays or vague communication.

Incorrect assumptions can lead to poor choices. A smooth delivery process is essential, but it can be challenging to evaluate. Not all manufacturers prioritize timeliness. Some may focus solely on cost reductions. Balancing costs and delivery reliability is key. It requires careful consideration and possibly, a trial period.

Evaluating Cost-Effectiveness vs. Quality in Raw Material Procurement Decisions

When selecting a chemical raw materials manufacturer, cost-effectiveness and quality are critical. The balance between these two factors can determine the success of your procurement strategy. A low-cost option may seem attractive, but poor quality can lead to failures or recalls. Consider the long-term implications of your choices. Cheaper materials often result in higher costs over time due to waste and inefficiency.

Tips: Research each manufacturer’s reputation. Check for reviews, certifications, and industry awards. Speak with past clients about their experiences. A solid reputation often indicates reliability and quality.

Evaluating raw materials should include a thorough analysis of both specifications and prices. Conduct testing to verify quality before making significant investments. This can prevent costly mistakes. Be wary of deals that seem too good to be true. It might be a signal of compromised quality.

Don't overlook local suppliers. They may offer better service and support. Establish relationships with them. Open communication can enhance your understanding of material performance. Take time to reflect on your choices. What has worked in the past? What didn’t? Learning from past experiences can guide you in making informed decisions.