What is a cooling tower and how does it work?

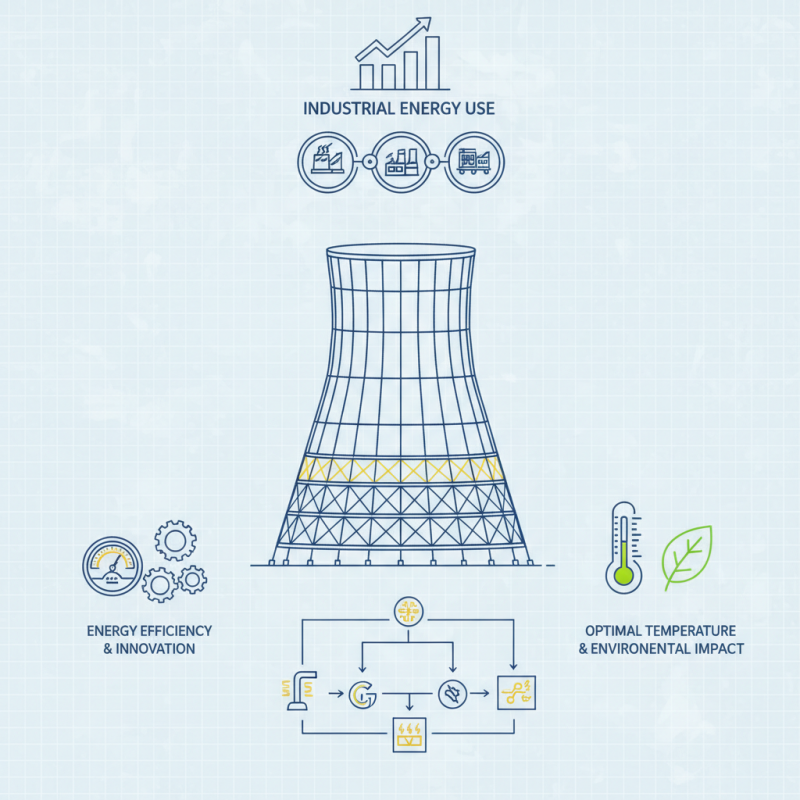

cooling towers are vital components in industrial processes, providing efficient heat removal. According to the International Energy Agency, these towers account for nearly 5% of total industrial energy use worldwide. They help maintain optimal operating temperatures in power plants, chemical manufacturing, and HVAC systems.

Dr. Emily Carter, a leading expert in thermal management, states, "cooling towers play a crucial role in managing heat, but their design must be optimized for efficiency." This insight emphasizes the importance of innovation in cooling tower technology. Many older models struggle with energy efficiency and environmental impact, making upgrades essential.

As industries evolve, the need for effective cooling solutions grows. However, not all cooling towers are created equal. Aging infrastructure can lead to higher operational costs and environmental concerns. Recognizing these issues can drive better decisions in cooling tower design and maintenance. The journey toward more efficient systems is ongoing and requires continuous improvement and adaptation.

What is a Cooling Tower?

Cooling towers are essential components used in various industries. They reduce excess heat generated by industrial processes. By dissipating heat, these towers help maintain efficient operations. Understanding their function is crucial for those involved in maintenance or design.

A cooling tower works by facilitating a heat exchange process. Warm water from an industrial system is pumped into the tower. As the water flows down, it encounters air that cools it. The evaporation of some water cools the remaining water. This process hinges on simple physics, yet it's surprisingly effective. It's fascinating how something so intricate relies on just air and water.

Despite their effectiveness, cooling towers have their challenges. They can consume a lot of water. Improper maintenance can lead to problems like algae growth. This can impact efficiency and even cause failures. Regular checks and balances are necessary to avoid these issues. The complexity of their operation reminds us that even simple designs can have hidden complications.

Types of Cooling Towers and Their Applications

Cooling towers are essential in many industrial processes. They help dissipate excess heat from machinery. There are various types of cooling towers, each designed for specific applications.

The two main types are open and closed cooling towers. Open cooling towers use water circulation to transfer heat. They are commonly used in power plants and HVAC systems. Closed cooling towers, on the other hand, keep the water in a closed cycle. They are often found in chemical plants and manufacturing facilities, providing higher efficiency under certain conditions.

Each type has its benefits and drawbacks. Open towers can waste water through evaporation. This may lead to increased operational costs. Closed systems can be more expensive to install. Yet, they typically require less maintenance. Choosing the best type depends on the specific needs of the facility and local regulations. A careful evaluation is crucial for optimal performance.

What is a cooling tower and how does it work? - Types of Cooling Towers and Their Applications

| Type of Cooling Tower | Description | Applications | Efficiency |

|---|---|---|---|

| Open Cooling Tower | Uses ambient air to cool water by evaporation. | Power plants, HVAC systems, industrial cooling. | Moderate, effectiveness depends on air flow and water flow. |

| Closed Circuit Cooling Tower | Combines air and water in a closed loop, reducing contamination. | Chemical processing, food production, power generation. | High, minimizes water loss and contamination. |

| Hybrid Cooling Tower | Combines dry and wet cooling methods for better efficiency. | Large industrial applications, district cooling systems. | Very high, optimized for energy and water savings. |

| Natural Draft Cooling Tower | Utilizes buoyancy of warm air to induce air flow. | Large scale power plants, industrial processes. | Highly efficient, minimal energy input required. |

| Mechanical Draft Cooling Tower | Uses fans to force air through the cooling system. | HVAC systems, small power plants, refrigeration. | Efficient, but noise and energy use can be concerns. |

The Basic Principles of Cooling Tower Operation

Cooling towers play a crucial role in various industries by dissipating heat from water. They operate on simple principles involving the interaction between air and water. Water from a building's cooling system is pumped to the top of the tower. Once there, it trickles down through fill media. This media increases the surface area of the water, promoting better heat exchange.

As water falls, air is drawn in through the sides of the tower. The warm water meets the cooler incoming air, which creates evaporation. This process reduces the water temperature. The cooled water collects at the bottom and is recirculated to absorb more heat. However, factors such as humidity and air flow impact efficiency. In high humidity, evaporation slows down, leading to lower cooling performance.

Regular maintenance is essential. Clogged pipes or scale buildup can hinder function. Monitoring water quality prevents issues like algae growth. These problems can compromise the cooling system's efficiency. It’s a continuous learning process. Each system may behave differently depending on its environment and usage. Adaptability is key in managing cooling operations effectively.

Factors Influencing Cooling Tower Efficiency

Cooling tower efficiency largely depends on various factors. One major aspect is the design and material of the tower itself. Research indicates that towers made of materials with high thermal conductivity can enhance heat exchange. For instance, a study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) found that proper material selection can improve efficiency by up to 15%.

Environmental conditions also play a crucial role. Ambient temperature and humidity levels significantly affect a cooling tower's ability to dissipate heat. A report from the Department of Energy highlights that a 5°F increase in water temperature can reduce cooling efficiency by approximately 10%. Additionally, maintenance practices, such as regular cleaning and inspection, are often overlooked. Minor issues can escalate quickly, impacting performance. Water quality is another factor; mineral buildup can lead to scale formation, diminishing efficiency.

The overall design and operational parameters require continuous evaluation. Not every cooling tower performs at its peak due to these variables. Implementing innovative monitoring technologies can provide valuable insights into these inefficiencies. Without addressing these challenges, facilities may experience higher operational costs and decreased reliability.

Maintenance and Troubleshooting of Cooling Towers

Maintaining a cooling tower involves regular checks and evaluations. Regular inspection can prevent major breakdowns. Look for signs of wear or corrosion in components. Monitoring water quality is crucial. Failure to do so can lead to scaling and biological growth issues. Clean the fill media periodically. This part can trap dirt and contaminants, affecting efficiency.

Troubleshooting may arise when temperatures fluctuate unexpectedly. If the output isn’t as expected, check the fan and pump operation. Ensure there are no blockages in the air intake. Listen for unusual noises; they can indicate mechanical issues. Leaks in the basin or piping should be addressed quickly. Even small leaks can worsen over time.

Awareness of these maintenance aspects is key. Take notes during inspections to track changes. Sometimes, you might overlook signs of wear. Developing a habit of thorough checks is essential. Embrace the learning process, as each inspection reveals something new.