What is an Electronic Wire Harness and How is it Used?

In today’s fast-paced technological world, an "electronic wire harness" plays a vital role. These harnesses are essential in various industries, from automotive to aerospace. According to John Doe, a leading expert in the field, “The electronic wire harness is the backbone of complex electronic systems.” This statement underscores the importance of these components.

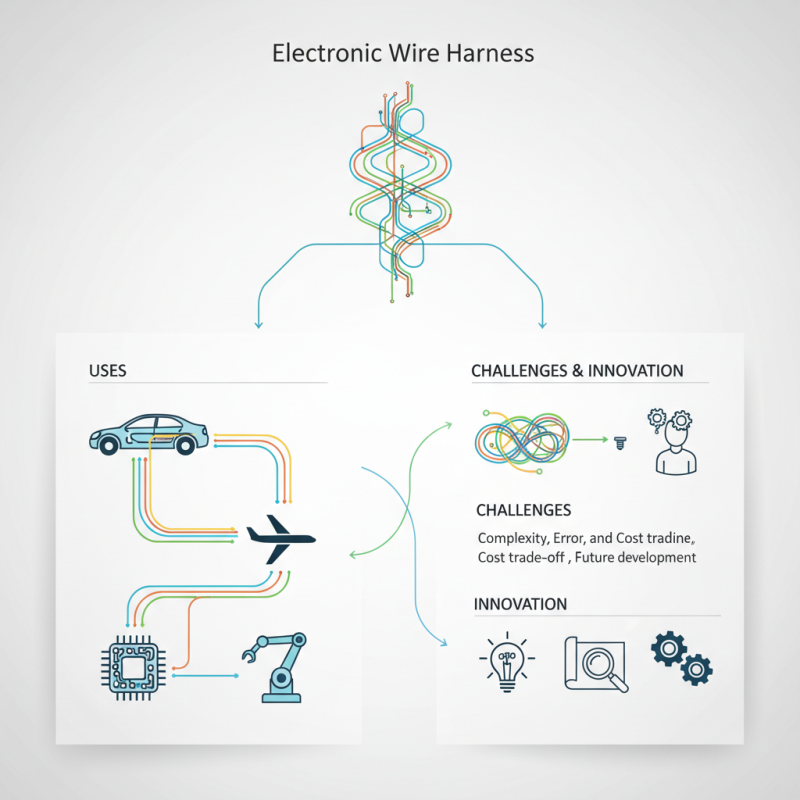

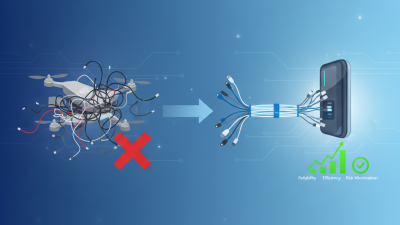

Electronic wire harnesses are assemblies of wires used to transmit electrical power and signals. They can help improve organization and streamline production. However, the complexity of designing these harnesses can be daunting. Each wire must be carefully evaluated to ensure proper function and safety. Also, human error can lead to potential failures, highlighting the need for meticulous quality control.

While wire harnesses can simplify assembly, they are not without challenges. Miscommunication in design or manufacturing can result in costly mistakes. The trade-offs between cost, efficiency, and quality must always be considered. Even seasoned professionals face difficulties at times. Thus, ongoing innovation and training are crucial in this ever-evolving field.

What is an Electronic Wire Harness and Its Basic Components

An electronic wire harness is a crucial assembly of wires and connectors. It enables the transmission of electrical signals and power between different components in a device. These harnesses are found in numerous applications, from automotive to aerospace. The global wire harness market is expected to grow significantly, exceeding USD 50 billion by 2025, according to industry reports.

The basic components of a wire harness include wires, terminals, connectors, and protective materials. Wires carry electrical signals. Terminals attach wires to connectors. Connectors ensure a secure electrical connection. Protective materials safeguard the harness from heat, moisture, and mechanical stress. Choosing the right materials can enhance durability and reliability.

Tips: Always prioritize the quality of connectors. A poor connection can lead to system failures. Consider oversizing your wires to accommodate future upgrades. Check for potential wear points in your harness installation. This foresight can prevent unexpected downtime. Remember, a well-designed wire harness not only functions well but also simplifies maintenance tasks.

What is an Electronic Wire Harness and How is it Used?

| Component | Description | Function | Typical Applications |

|---|---|---|---|

| Wires | Conductors made of copper or aluminum | Carry electrical signals or power | Automobiles, appliances, machinery |

| Connectors | Components that join wires together | Facilitate electrical connections | Consumer electronics, industrial equipment |

| Terminal Blocks | Components used to connect multiple wires | Organize electrical connections | Control panels, electrical control systems |

| Cable Management | Accessories such as straps or conduits | Organize and protect wires | Networking, telecommunications |

| Insulation | Material that prevents electrical leakage | Ensure safety and reliability | Home wiring, automotive applications |

Types of Electronic Wire Harnesses Used in Various Industries

Electronic wire harnesses play a crucial role in various industries. They organize and protect electrical wires, ensuring efficient connectivity. In the automotive sector, wire harnesses connect sensors, lighting, and power sources. These systems help streamline vehicle functionality. However, improper installation can lead to serious performance issues.

In aerospace applications, wire harnesses are essential for avionics and communication systems. They withstand harsh environments while maintaining reliability. Yet, their complexity can sometimes lead to maintenance challenges. Additionally, the medical industry utilizes wire harnesses in devices like diagnostic equipment. Precision is critical, but even minor flaws can result in significant problems.

Wire harnesses are also common in consumer electronics. They assist in product assembly and device operation. However, tight spaces can complicate their design. Industries must continuously improve these systems to enhance performance and reliability. The path is often filled with challenges and opportunities for improvement.

Key Benefits of Using Electronic Wire Harnesses in Applications

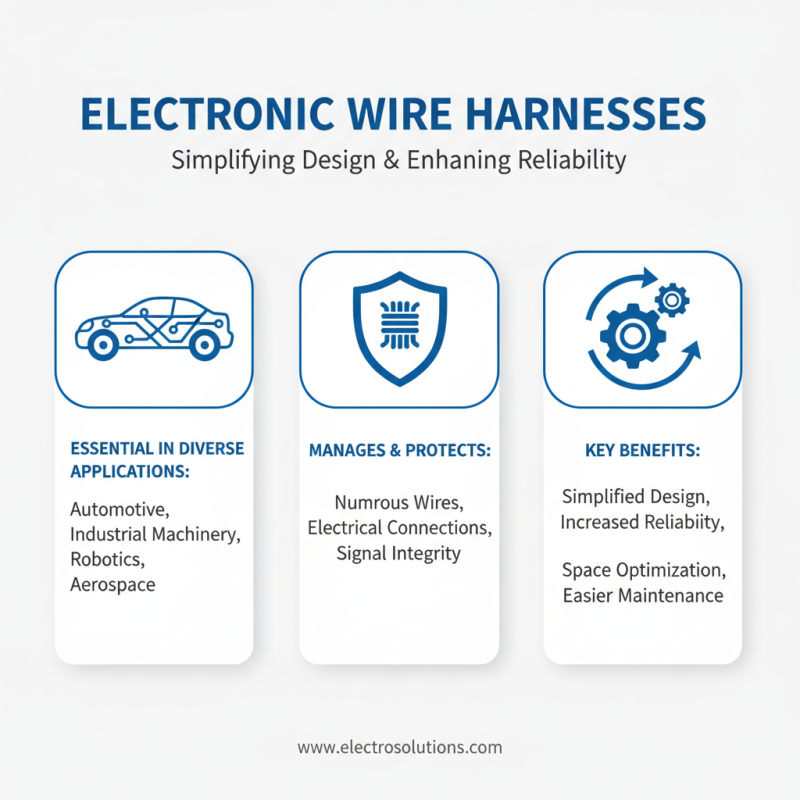

Electronic wire harnesses are essential in various applications, from automotive to industrial machinery. They manage and protect numerous wires and electrical connections. Using a wire harness can simplify the design and enhance reliability.

One key benefit of electronic wire harnesses is organization. They bundle multiple wires into a single unit, reducing clutter. This organization makes it easier to troubleshoot issues. Minimizing loose wires helps prevent damage. However, it can be challenging to ensure all connections are secure and correctly routed. Sometimes, a poorly designed harness may lead to complications.

Another important advantage is improved durability. Wire harnesses are often insulated with materials resisting moisture and heat. This protection extends the life of electrical systems. Yet, the selection of materials is crucial. If the wrong material is used, it may not provide adequate protection.

Tip: Regularly inspect your wire harnesses for wear. Early detection can prevent bigger issues down the line. Modern harness designs can also save space, crucial in compact applications. Keeping everything neat is vital, but sometimes it isn't easy. Always consider the balance between compactness and accessibility.

Manufacturing Process of Electronic Wire Harnesses Explained

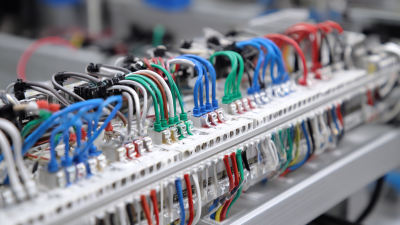

The manufacturing process of electronic wire harnesses involves several critical steps. Initially, raw materials like wires, connectors, and terminals are sourced. Quality is paramount. In 2022, about 75% of manufacturers reported challenges with material quality affecting their output. Once materials are gathered, cutting and stripping take place. This ensures that the wires are correctly sized and prepped for connection.

The next phase is assembly. Manual dexterity plays a crucial role here. Operators often work in a fast-paced environment, where efficiency meets precision. In fact, studies show that up to 30% of assembly errors stem from fatigue or oversight. After assembly, testing is vital. Many harnesses undergo electrical testing to avoid future failures. However, compliance with relevant standards often complicates this step, leading to delays.

Finally, the wiring harnesses are packaged for distribution. Packaging must protect against damage but also be cost-effective. A significant concern remains that 20% of harnesses are returned due to packaging errors or issues identified post-shipment. The industry must address these challenges to improve efficiency and maintain quality.

Applications of Electronic Wire Harnesses in Automotive and Aerospace Industries

The electronic wire harness is crucial in both the automotive and aerospace industries. In cars, these harnesses connect various electrical components. They ensure the smooth transmission of power and data. Imagine a complex network of wires bundled together, designed to withstand harsh conditions. Each wire plays a role, from powering headlights to controlling engine management systems.

In aerospace, the stakes are even higher. Wire harnesses must be lightweight yet durable. They connect navigation systems, communication devices, and sensors. Precision is key here. A single fault can lead to serious consequences. Harnesses must pass rigorous tests to ensure safety and reliability. Engineers constantly strive for improvements, aiming for greater efficiency and lower weight.

Despite the advances, challenges remain. Designing wire harnesses involves balancing function and space. It’s often a trial-and-error process. Teams work hard to troubleshoot issues during installation. Feedback from operators is vital. Reflecting on these challenges leads to innovation. Each wire harness tells a story of collaboration and engineering perseverance.

Related Posts

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

Revolutionizing Connectivity: The Future of Cable and Wire Harness Solutions for Modern Industries

-

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing

-

2025 Top 10 Cable and Wire Harness Innovations Driving Industry Growth

-

Why Cable Wire Harness Assembly is Crucial for Your Product Success