5 Essential Tips for Choosing the Best Wire Harness Manufacturing Equipment

In the rapidly evolving landscape of electrical and electronic manufacturing, selecting the right wire harness manufacturing equipment is crucial for maintaining competitiveness and ensuring high-quality production. According to the latest data from the Global Wire Harness Market Report, the industry is projected to reach a value of $62 billion by 2025, highlighting the increasing demand for advanced manufacturing solutions. With technological advancements paving the way for smarter and more efficient processes, manufacturers must navigate a plethora of options to identify equipment that best meets their operational needs. This blog will provide essential tips to help organizations make informed decisions, ensuring they invest in equipment that not only enhances productivity but also aligns with industry standards and future growth potential.

Key Factors to Consider When Selecting Wire Harness Manufacturing Equipment

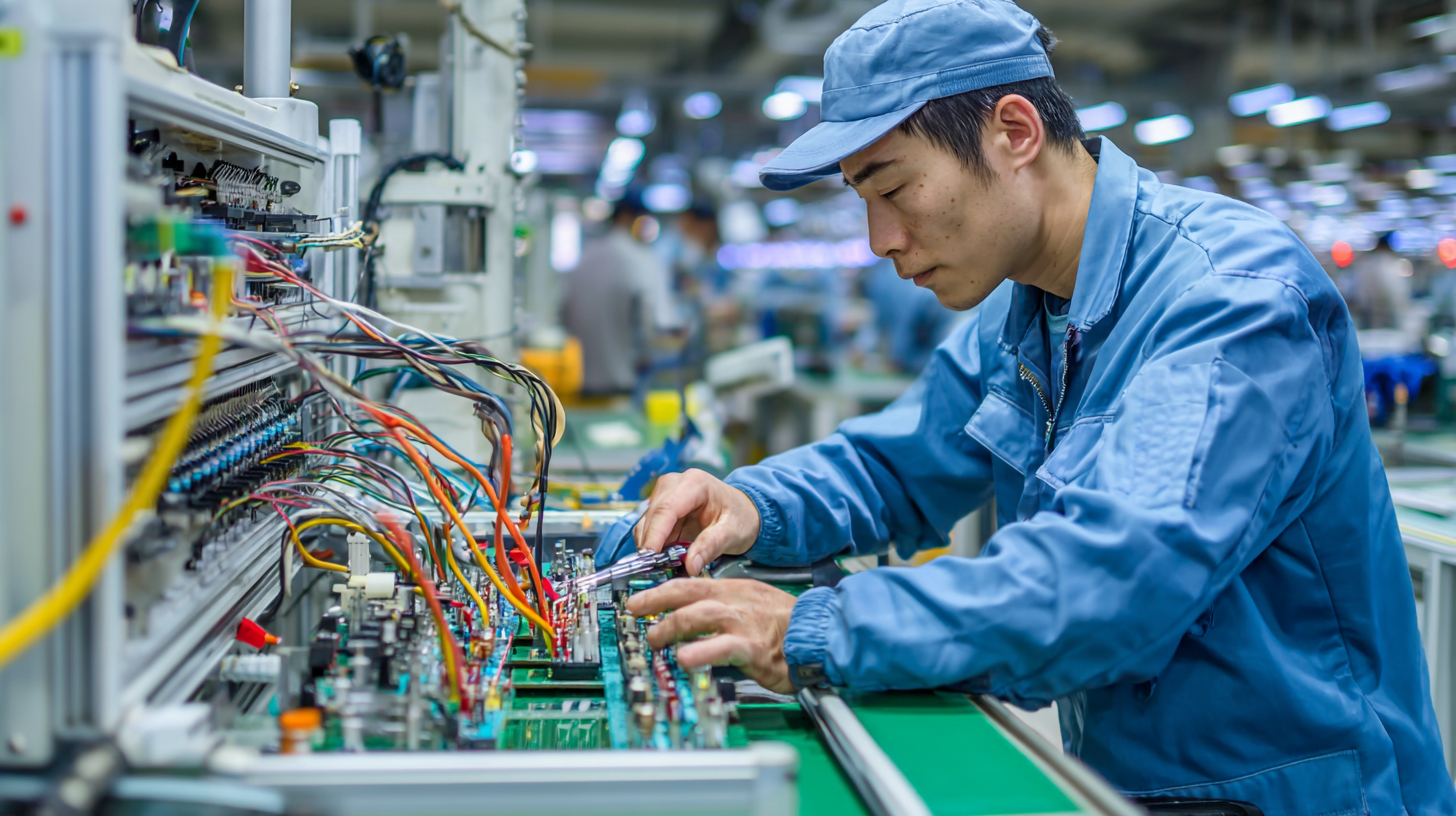

When selecting wire harness manufacturing equipment, several key factors should guide your decision-making process. First and foremost, consider the specific requirements of your production environment. Different manufacturers may need equipment that caters to varying production volumes, material types, and complexity of the assemblies. Assess whether your operations are more suited to automated solutions, semi-automated systems, or manual equipment, as this will influence both your output efficiency and labor costs.

In addition to production needs, you should evaluate the reliability and durability of the equipment. Investing in high-quality machinery that requires less maintenance can significantly reduce downtime and operational costs in the long run. Furthermore, take into account the scalability of the equipment. As your business grows, your manufacturing needs may change, so opt for versatile solutions that can adapt to new processes or increased production loads. Lastly, remember to factor in the level of support and training provided by the manufacturer, as a strong relationship can facilitate smoother operations and troubleshooting down the line.

5 Essential Tips for Choosing the Best Wire Harness Manufacturing Equipment

Understanding Technological Advancements in Wire Harness Production Machinery

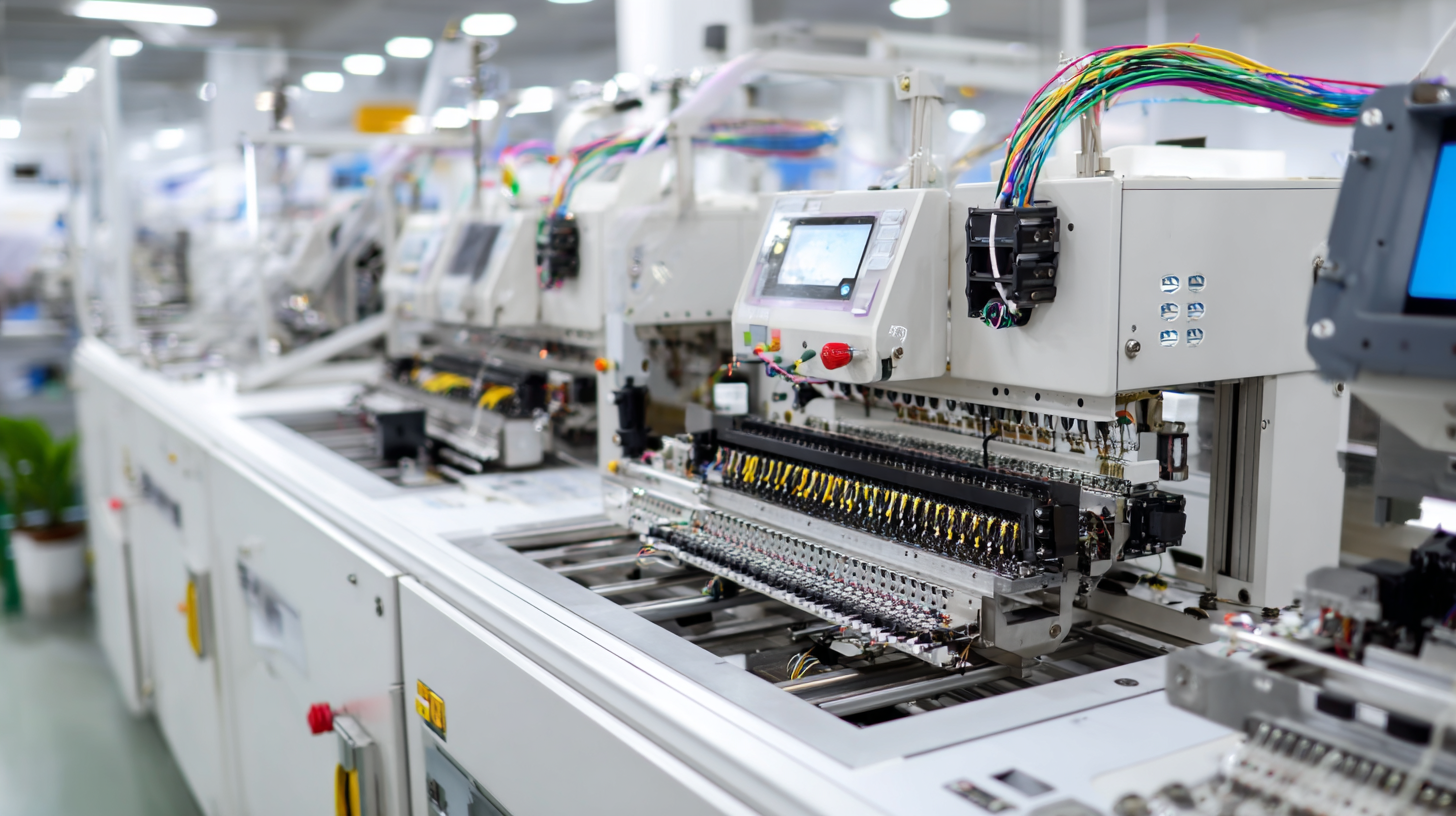

When it comes to wire harness production, understanding the technological advancements in manufacturing equipment is crucial for achieving efficiency and maintaining high quality. Modern wire harness manufacturing machinery has evolved significantly, incorporating automation, precision, and smart technology features that streamline production processes. For example, the integration of robotics in wire cutting and terminating has drastically reduced manual labor, allowing companies to scale production while minimizing human error.

Moreover, innovations such as Industry 4.0 and IoT-enabled devices provide real-time data monitoring and analysis, enabling manufacturers to optimize workflows and predict maintenance needs. These advancements not only enhance productivity but also improve the ability to adapt quickly to changing market demands. By considering these technological trends, businesses can make informed decisions when selecting wire harness manufacturing equipment, ensuring they invest in tools that will provide long-term benefits and competitive advantages in the fast-paced industrial landscape.

Evaluating Cost-Effectiveness and ROI in Wire Harness Equipment Investments

When investing in wire harness manufacturing equipment, understanding the cost-effectiveness and potential return on investment (ROI) is crucial. According to recent industry insights, the growing demand for efficient and sustainable manufacturing technologies has pushed companies to reevaluate their equipment choices. By conducting a thorough cost-benefit analysis, businesses can identify equipment that not only meets their production needs but also delivers long-term savings and efficiency improvements.

Consideration of advanced materials, suchu as copper clad aluminum wires, is another important factor in maximizing ROI. These materials are increasingly being adopted for their excellent conductivity and cost-efficiency. Companies that strategically invest in machinery tailored for these materials can optimize their production processes and reduce operational costs. Furthermore, integrating new technologies and energy solutions can lead to enhanced productivity and lower energy consumption, making the investment more viable in the long run. Evaluating these aspects ensures that companies make informed decisions that align with their financial objectives while adapting to industry trends.

Assessing Quality Standards and Compliance in Wire Harness Manufacturing Tools

When selecting wire harness manufacturing equipment, assessing quality standards and compliance is critical to ensuring operational efficiency and product reliability. First, it’s essential to understand the regulatory environment relevant to your industry. Many sectors, such as automotive and aerospace, have stringent compliance requirements that dictate the materials and construction standards for wire harnesses. Evaluating manufacturers based on their adherence to recognized standards, such as ISO, IPC, or SAE, can help ensure that the equipment you choose will ultimately lead to high-quality outputs.

The next step is to review the testing and quality assurance procedures implemented by the equipment vendors. This could include in-circuit testing, electrical performance evaluations, and environmental stress testing. Equipment that incorporates inline quality checks can significantly minimize defects and reduce waste, thereby improving overall productivity. Additionally, consider manufacturers who offer comprehensive documentation and support, which can assist in maintaining compliance throughout the manufacturing lifecycle. Prioritizing these aspects when choosing wire harness production tools will result in a more robust and compliant manufacturing process, leading to better end products and customer satisfaction.

Exploring Future Trends in Wire Harness Manufacturing Equipment for 2025 and Beyond

As we look toward 2025 and beyond, the wire harness manufacturing industry is on the brink of significant transformation. The integration of advanced technologies such as automation, artificial intelligence, and IoT will redefine production processes. Manufacturers must stay ahead of these trends by investing in machinery that not only meets today's requirements but also adapts to future needs. This foresight will enable companies to enhance productivity while reducing operational costs.

When selecting wire harness manufacturing equipment, consider the versatility of the machine. Opt for equipment that can handle various wire types and sizes, allowing for flexibility in production. Additionally, ensure that the machinery is compatible with upcoming technologies, facilitating seamless integration into future manufacturing systems.

Another crucial tip is to prioritize energy efficiency. With sustainability becoming a key concern in manufacturing, investing in energy-efficient equipment can lead to long-term cost savings and a reduced environmental footprint. As we embrace the trends of the future, choosing the right machinery will position manufacturers to thrive in an evolving industry landscape.

5 Essential Tips for Choosing the Best Wire Harness Manufacturing Equipment - Exploring Future Trends in Wire Harness Manufacturing Equipment for 2025 and Beyond

| Tip Number | Tip Description | Future Trend | Estimated Impact by 2025 |

|---|---|---|---|

| 1 | Evaluate automation capabilities | Increased integration of AI in manufacturing processes | Up to 30% increase in efficiency |

| 2 | Check flexibility for customization | Rise in demand for bespoke wire harness solutions | Customization to enhance market adaptability |

| 3 | Assess quality control measures | Implementation of real-time monitoring systems | Reduction in defect rates by up to 40% |

| 4 | Consider ease of maintenance | Growth of modular equipment designs | Decreased downtime and maintenance costs by 25% |

| 5 | Investigate sustainability practices | Shift towards environmentally sustainable materials | Positive impact on brand reputation and compliance with regulations |