10 Essential Tips for Choosing Cable and Wire Harness Solutions

In the rapidly evolving field of cable and wire harness solutions, making informed choices is crucial. Industry expert, John Smith, emphasizes, "Selecting the right cable and wire harness can determine the success of your electrical systems." This statement highlights the importance of careful consideration in the selection process.

Understanding the specific needs of your project is vital. Different applications require unique solutions. For instance, a high-temperature environment may necessitate specialized insulation. Pay attention to the materials used in cable and wire harness production. These can significantly influence durability and performance.

Additionally, manufacturers vary in quality and service. It’s essential to do thorough research on potential suppliers. Look for certifications that demonstrate reliability in their products. Don’t overlook customer reviews; they can provide valuable insights. Reflect on your choices and remember, mistakes can be costly. In the world of cable and wire harness, precision matters deeply.

Understanding the Importance of Cable and Wire Harness Solutions

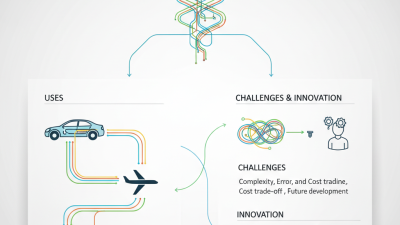

Choosing the right cable and wire harness solutions is crucial. These components connect and manage electrical systems in various industries. A poor choice can lead to malfunctions and costly repairs. Reports indicate that faulty connections account for nearly 30% of electrical failures in manufacturing. This highlights the need for careful selection.

Understanding how cable and wire harness solutions impact system performance is vital. For instance, the wrong wire gauge can cause overheating. On average, improper wiring can reduce system efficiency by 20%. Also, environmental factors like temperature and moisture levels affect durability. Proper insulation and materials are essential for longevity.

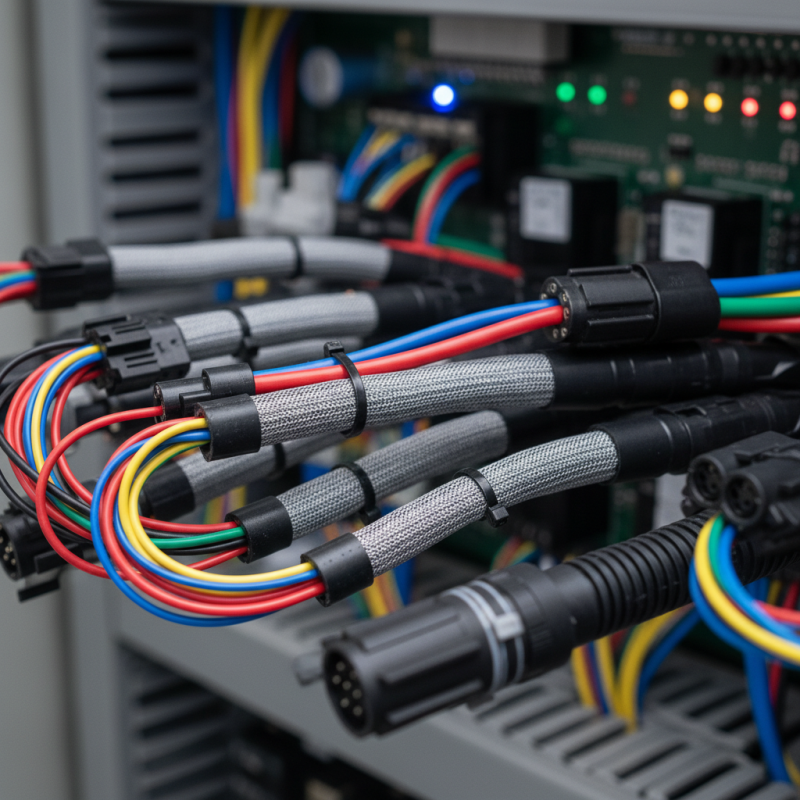

Many organizations fail to recognize the intricacies involved in these solutions. Decision-makers often overlook the specifics, like connectors and shielding. Common mistakes include underestimating the complexity of installation. Balancing cost and quality is a challenge. Without proper attention, the entire system’s reliability could be jeopardized.

Evaluating Different Types of Cables and Wires for Your Needs

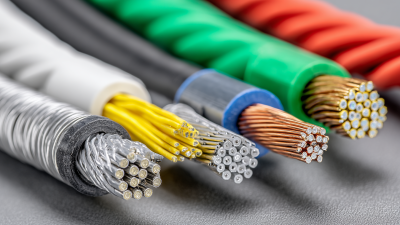

When evaluating different types of cables and wires for your project, it’s essential to consider their specific applications. Each cable and wire harness has characteristics tailored to particular environments and tasks. For instance, industrial settings may require tough, durable connectors. In contrast, lightweight options might be suitable for consumer electronics. Understanding these distinctions will guide you to the right choice.

Tip: Check the insulation type. Different materials offer varying levels of protection against heat, moisture, and chemicals. Make sure the insulation is compatible with your usage scenario.

Another critical factor is the wire gauge you select. Thicker wires can carry more current but may be less flexible. If your design requires tight bends, a thinner wire could be better, but you should heed the current capacity limits.

Tip: Consider future needs. Your project may expand, requiring more connections. Choose a wire harness that can accommodate additional wires later. This foresight can prevent costly redesigns down the line.

Assessing the Project Requirements for Cable and Wire Harness Selection

Selecting the right cable and wire harness solutions is crucial for any project. The complexity of the requirements can vary significantly. According to a study by the Institute of Electrical and Electronics Engineers (IEEE), nearly 35% of projects face delays due to improper wiring choices. This emphasizes the need for a thorough assessment of project specifications before making a decision.

When evaluating requirements, factors such as electrical load, environmental conditions, and installation space are vital. More than 45% of engineering teams overlook environmental factors, leading to failures in harsh conditions. For instance, choosing materials that are not resistant to moisture could result in long-term issues. Each project brings unique challenges, and understanding these nuances is key to a successful outcome.

Additionally, the construction costs can be impacted by the initial choices. A report from the National Electrical Manufacturers Association (NEMA) indicates that improper harness design can inflate costs by up to 20%. Rethinking your options may save time and financial resources in the long run. Each decision should be influenced by real-world applications and past project evaluations to prevent costly mistakes.

Identifying Key Features and Specifications in Harness Solutions

When choosing cable and wire harness solutions, identifying key features and specifications is crucial. Start with the type of insulation available. The right insulation affects performance in various environments. Consider temperature ratings. A harness designed for severe conditions may be necessary. Always check the gauge of the wire. A wire's thickness impacts current capacity and flexibility.

Next, look into the harness configuration. This includes the number of wires and connectors involved. A simple design might seem appealing, but it may not accommodate future needs. Complexity can lead to challenges, especially during installation. Examine the connectors themselves; they must be reliable and capable of withstanding strain.

Always assess the specific requirements of your project. Each application might require different features. Reflection on these specifications can uncover potential issues. Don't overlook the importance of compliance with industry standards. Failure to adhere can lead to safety concerns down the road. Ensure the harness solution you choose meets all necessary criteria for your application.

10 Essential Tips for Choosing Cable and Wire Harness Solutions - Identifying Key Features and Specifications in Harness Solutions

| Tip No. | Key Feature | Specification | Importance |

|---|---|---|---|

| 1 | Material Compatibility | PVC, XLPE, Silicone | Essential for durability |

| 2 | Temperature Rating | -40°C to +125°C | Critical for performance in harsh environments |

| 3 | Wire Gauge | AWG 18 to 10 | Influences current capacity |

| 4 | Connector Types | Molex, JST, D-sub connectors | Affects connectivity and reliability |

| 5 | Shielding Options | Unshielded, Foil, Braided | Reduces interference |

| 6 | Length Requirements | Custom Length | To fit specific applications |

| 7 | Environmental Ratings | IP67, IP68 | For waterproof and dustproof needs |

| 8 | Compliance Standards | UL, CSA, RoHS | Ensures safety and environmental compliance |

| 9 | Strain Relief Features | Cable ties, Heat shrink | Prevents damage from bending |

| 10 | Testing and Certifications | Test reports, Certificates | Verifies performance criteria |

Considering Cost, Quality, and Manufacturer Reputation in Your Choice

When choosing cable and wire harness solutions,

cost is a primary factor. A recent industry report stated that cable assembly costs can vary by over 30% based on design complexity. Custom designs, for example, often have higher costs due to the specific requirements and materials.

However, opting for cheap solutions isn't always ideal. Quality can suffer, leading to failures and additional costs.

Quality influences longevity. A study revealed that high-quality wire harnesses decrease failure rates by up to 25%. Reliable materials, such as high-grade copper and specific insulation types, contribute to better performance. A poor choice may result in higher lifetime costs due to replacements and repairs.

Manufacturer reputation plays a crucial role in your decision. An industry survey found that 70% of companies prefer suppliers with proven track records. Established manufacturers often provide warranties and customer support, which is vital when issues arise. Newer or less-known suppliers may lack these protections, leading to uncertainties in long-term projects. Understanding these dynamics is essential for making informed decisions in this sector.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

Revolutionizing Connectivity: The Future of Cable and Wire Harness Solutions for Modern Industries

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

-

What is an Electronic Wire Harness and How is it Used?

-

The Future of Harness Assembly Driven by Innovation and Global Demand