7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

The demand for harness cable assembly solutions has skyrocketed in recent years, driven by rapid advancements in technology and the growing need for reliable electrical connectivity across various industries. According to a report by Fortune Business Insights, the global market for cable assembly is projected to reach $83.11 billion by 2028, expanding at a compound annual growth rate (CAGR) of 5.6% from 2021. In 2024, sourcing the best harness cable assembly has never been more critical, as businesses increasingly rely on these components to enhance the performance and efficiency of their products. With a plethora of options available, it is essential to adopt strategic sourcing techniques that align with both quality standards and cost-effectiveness. This blog will explore seven essential tips for navigating the complexities of sourcing harness cable assemblies in the coming year, ensuring that your organization remains competitive in this fast-evolving landscape.

Understanding the Changing Landscape of Harness Cable Assembly Technology in 2024

The harness cable assembly industry is experiencing transformative changes in 2024, driven by advancements in technology and increasing demands for efficiency. According to a recent report by MarketsandMarkets, the global harness cable assembly market is projected to grow from $54.3 billion in 2023 to $76.2 billion by 2028, reflecting a compound annual growth rate (CAGR) of 7.1%. This remarkable growth underscores the burgeoning need for more reliable and sophisticated cable assemblies across multiple sectors, including automotive, aerospace, and consumer electronics.

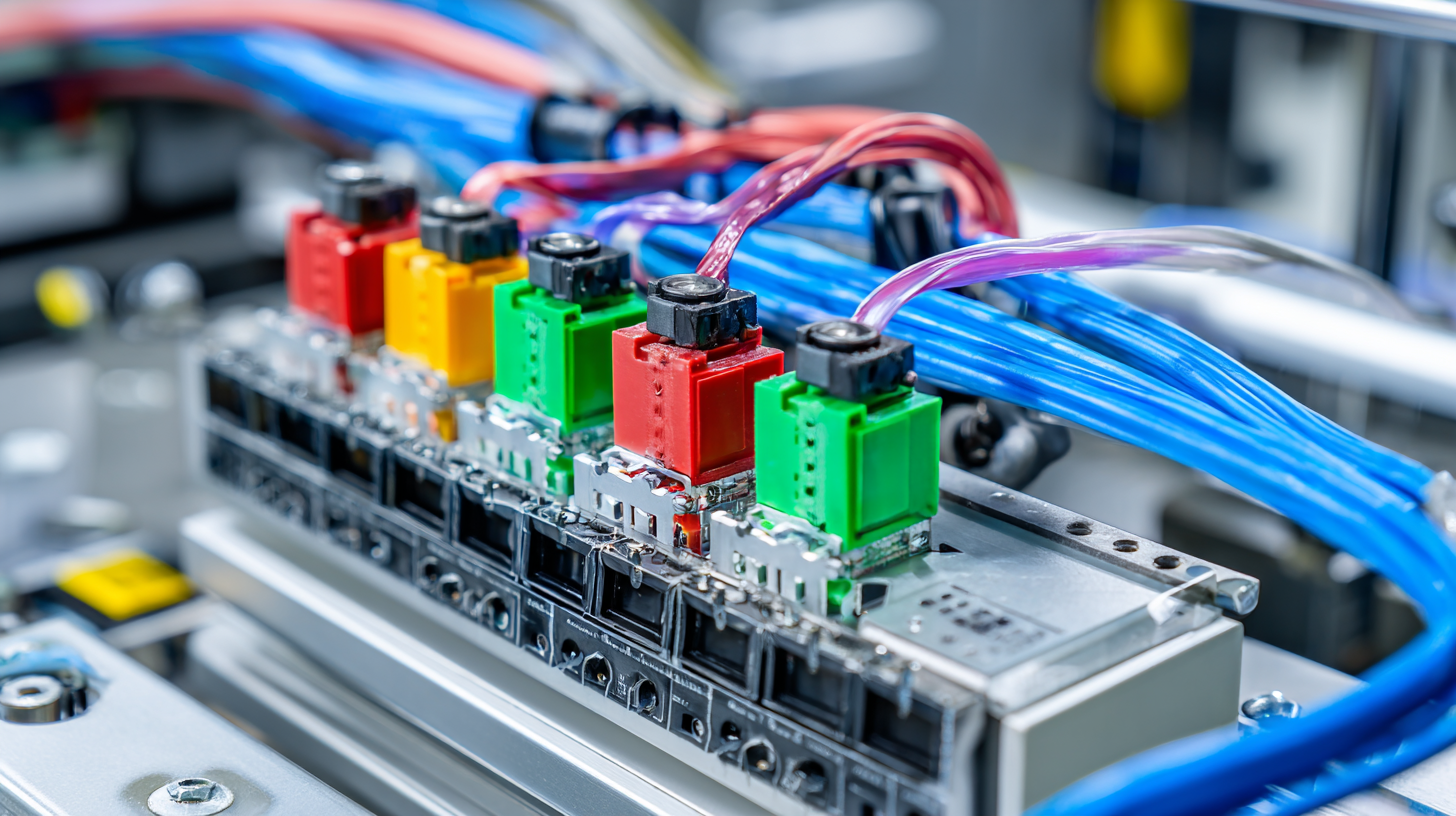

In response to this shifting landscape, manufacturers are increasingly adopting new materials and manufacturing techniques to enhance the performance and durability of their products. For instance, the use of high-performance thermoplastic elastomers (TPEs) is gaining traction due to their superior flexibility and resistance to harsh environmental conditions. Additionally, the integration of smart technology such as IoT and AI facilitates real-time monitoring of cable assemblies, providing critical data that helps in optimizing performance and reducing maintenance costs. As a result, businesses must stay abreast of these developments to ensure they are sourcing the best harness cable assembly solutions tailored for their specific needs in 2024.

Key Factors to Consider When Sourcing Quality Harness Cable Assemblies

When sourcing quality harness cable assemblies, several key factors come into play that can significantly influence the performance and durability of your final product.

First and foremost, understanding material specifications is crucial. According to a recent report by MarketsandMarkets, the global wire and cable market size is expected to reach $345.19 billion by 2027, driven by rising demand in diverse sectors including automotive and telecommunications. Selecting high-grade materials, such as stranded copper or specialized polymers, can enhance conductivity and protect against environmental challenges.

Another vital consideration is the manufacturing process. Industry standards, such as IPC/WHMA-A-620, provide benchmarks for quality assurance in cable assembly production. Implementing rigorous testing protocols during the manufacturing phase ensures that the assemblies can withstand not only mechanical strain but also thermal and chemical exposure. Additionally, collaborating with manufacturers who implement automated processes can result in lower defect rates and improved consistency. As highlighted in the latest report by ResearchAndMarkets, companies that prioritize these factors are better positioned to maintain competitive advantages in increasingly demanding market conditions.

Evaluating Manufacturers: What to Look for in 2024 and Beyond

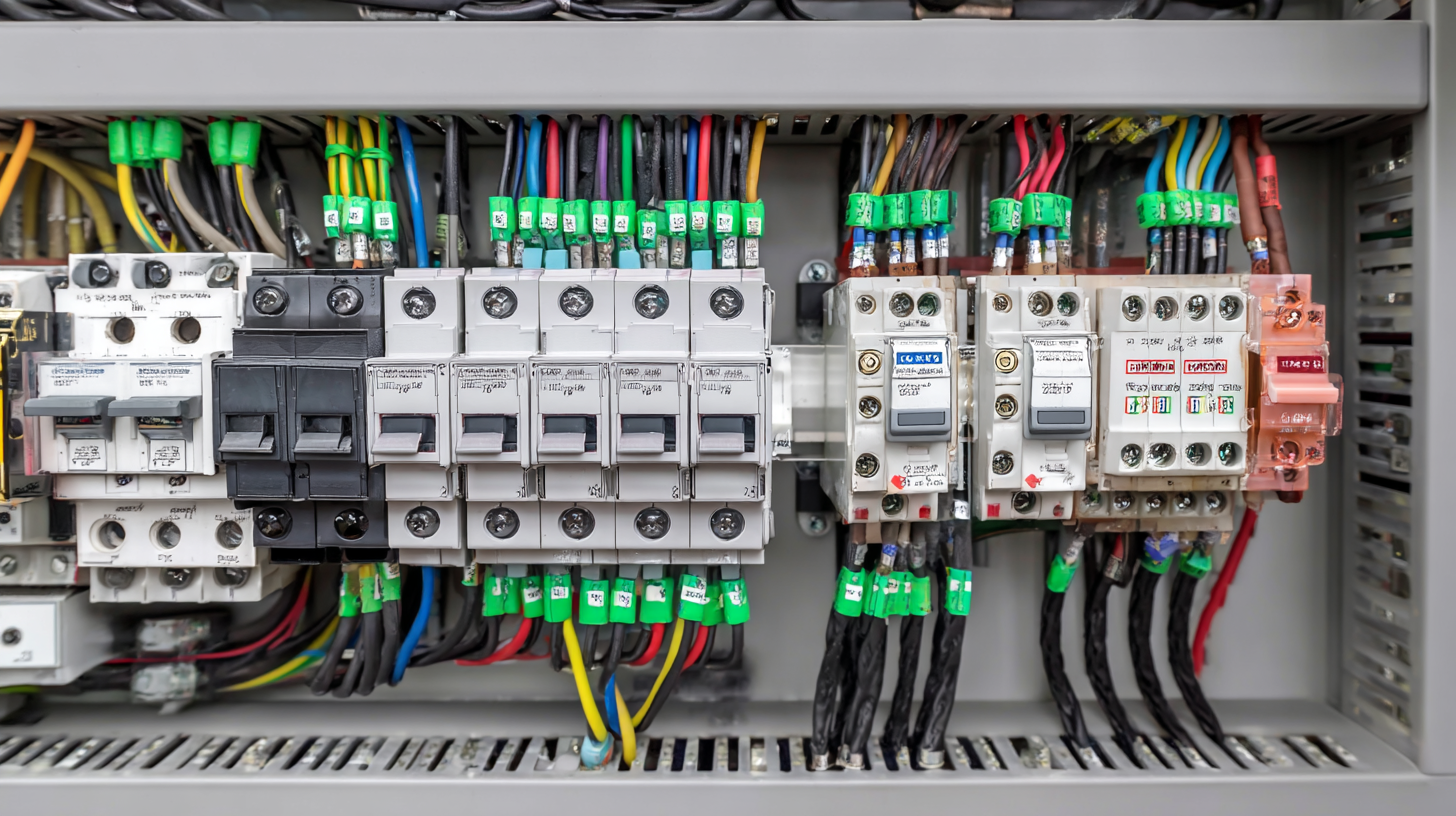

When evaluating manufacturers for harness cable assemblies in 2024 and beyond, it's crucial to adopt a systematic approach. Start by assessing the manufacturer's experience and expertise in the industry. Look for companies that have a proven track record of delivering high-quality products, as this can significantly impact reliability and performance. Additionally, consider their specialization in the specific type of harness cable assembly you require, as tailored expertise can enhance the overall product quality.

Another important factor to examine is the manufacturer's compliance with industry standards and certifications. Ensure they adhere to relevant guidelines such as ISO, IPC, or UL, which indicate a commitment to quality and safety. Furthermore, engage in conversations about their quality control processes and material sourcing, as these elements are essential for ensuring that the assemblies meet your specifications and standards. Establishing a strong partnership with a manufacturer that prioritizes transparency and communication will ultimately lead to a more successful sourcing experience.

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

| Criteria | Description | Importance (1-10) | Notes |

|---|---|---|---|

| Manufacturer Experience | Evaluate the years in business and their expertise in cable assembly. | 9 | Long-term experience often indicates reliability. |

| Quality Certifications | Check for ISO and other relevant quality certifications. | 10 | Certifications ensure adherence to industry standards. |

| Material Sourcing | Assess where and how materials are sourced for the assemblies. | 8 | High-quality materials lead to better performance and durability. |

| Customization Options | Look for flexibility in customizing harness assemblies to your needs. | 7 | Customization can enhance product fit and efficiency. |

| Lead Time | Consider the manufacturer's ability to meet deadlines. | 8 | Quick turnaround times can be critical for project success. |

| Customer Reviews | Look for testimonials or reviews from previous clients. | 7 | Positive feedback can indicate a trustworthy supplier. |

| After-Sales Support | Ensure support is available for troubleshooting after purchase. | 9 | Good support can save time and resources down the line. |

Sustainability in Harness Cable Assemblies: Trends and Considerations

As we move into 2024, sustainability in harness cable assemblies is becoming an increasingly significant consideration for manufacturers and consumers alike. The push for eco-friendly materials and processes is reshaping the industry, prompting companies to explore alternatives that reduce environmental impact. This shift includes the use of recyclable materials, such as biodegradable plastics and metal components that can be reclaimed after their lifecycle. By prioritizing sustainable sourcing, businesses not only contribute to a healthier planet but also meet the growing demand from consumers for responsible practices.

Furthermore, adopting sustainable practices in harness cable assemblies can also enhance brand reputation and customer loyalty. Companies that emphasize green processes often attract environmentally conscious buyers who prefer to support businesses aligned with their values. Additionally, navigating compliance with evolving environmental regulations can safeguard businesses from potential legal challenges. Ultimately, integrating sustainability into the design and manufacturing of harness cable assemblies reflects not just a commitment to the environment but also to innovation and long-term viability in an increasingly competitive market.

Harness Cable Assembly Sustainability Trends in 2024

Creating an Efficient Sourcing Checklist for Your Harness Cable Needs

When it comes to sourcing the best harness cable assembly, establishing a comprehensive checklist can streamline the process and ensure you meet all your technical needs. Start by defining your specific requirements, including the type of cable, connectors, and any unique specifications necessary for your project. Consider factors like the environment where the assembly will be used—will it need to withstand exposure to heat, moisture, or chemicals? This clarity will significantly aid in evaluating potential suppliers.

Next, prioritize quality and compliance. Research manufacturers that adhere to industry standards and certifications. A detailed supplier evaluation checklist should include aspects such as material quality, production capabilities, and previous customer feedback. By assessing suppliers against these criteria, you can narrow down your options effectively. Additionally, don’t overlook the importance of lead times and pricing, as both can significantly impact your project timelines and budgets. A well-organized sourcing checklist will not only guide you in finding the right harness cable assembly but also enhance your overall procurement strategy in 2024.