Exploring the Future of Wire Harness Manufacturing: Innovations That Are Shaping the Industry

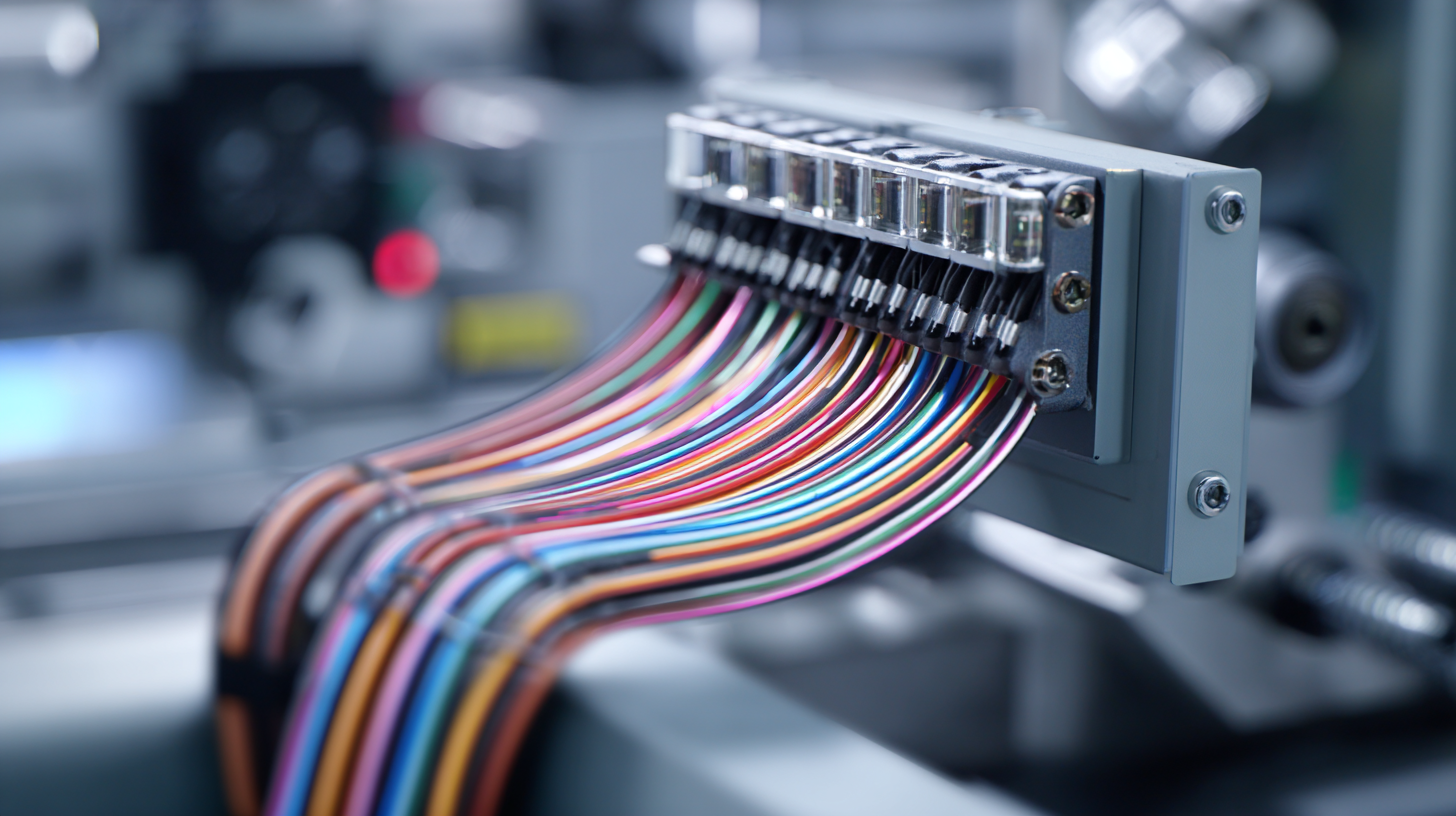

As the landscape of wire harness manufacturing continues to evolve, innovations are playing a pivotal role in shaping the future of this crucial industry. From advancements in materials and technologies to streamlined production processes and enhanced automation, the potential for growth and efficiency is immense. This article seeks to explore the latest trends and developments that are redefining wire harness manufacturing, highlighting how these innovations can lead to significant improvements in design, reliability, and cost-effectiveness. By embracing emerging technologies and adapting to changing market demands, manufacturers can not only meet the current needs of various sectors but also position themselves for long-term success in an increasingly competitive environment.

Join us as we delve into the strategies and innovations that are paving the way for a new era in wire harness manufacturing.

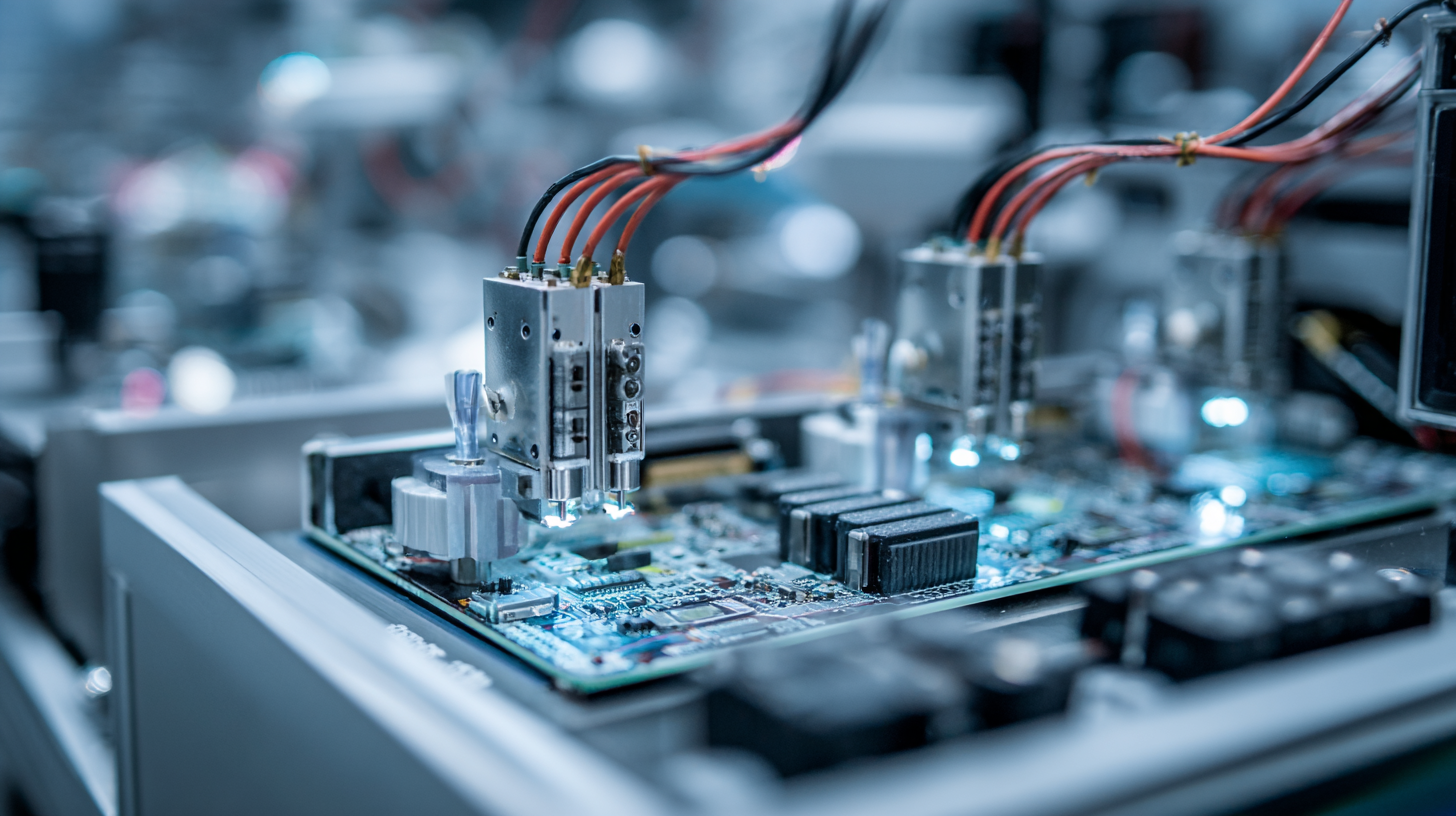

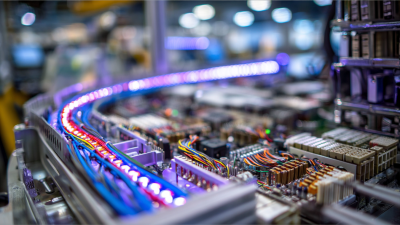

Trends in Wire Harness Manufacturing: Embracing Automation and AI Technologies

The wire harness manufacturing industry is witnessing transformative changes driven by automation and artificial intelligence (AI) technologies. According to a report by MarketsandMarkets, the global wire harness market is projected to reach $228.67 billion by 2026, growing at a CAGR of 3.2%. This growth is largely attributed to the increasing demand for advanced manufacturing techniques that improve efficiency and reduce costs. Automation allows manufacturers to streamline their production processes, leading to enhanced precision and faster turnaround times. AI technologies can optimize design processes and predictive maintenance, ensuring greater reliability and quality in output.

Tips: To stay competitive, manufacturers should consider investing in automated assembly machines that integrate seamlessly with their existing systems. Additionally, adopting AI-driven analytics can help in forecasting demand and managing inventory more effectively.

Furthermore, the implementation of robotic process automation (RPA) is revolutionizing the sector by minimizing human error and maximizing productivity. According to a recent study by Deloitte, organizations that have embraced such technologies report a productivity increase of up to 30%. As these innovations continue to permeate the wire harness manufacturing landscape, companies must remain agile and ready to adapt to these advancements.

Tips: Regular training and upskilling of the workforce in these new technologies will equip teams to leverage them fully, maximizing their potential benefits.

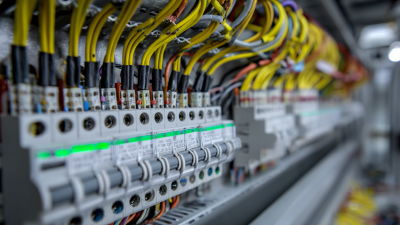

Sustainable Practices in Wire Harness Production: Reducing Environmental Impact

As the wiring harness manufacturing industry evolves, a growing focus on sustainable practices is reshaping production methods. The demand for eco-friendly solutions is intensifying, driven by the need to reduce environmental impacts. According to industry reports, incorporating renewable energy sources, such as solar, wind, and hydropower, into the manufacturing process can significantly lower carbon footprints and promote efficient resource use.

Tips for manufacturers looking to enhance sustainability include investing in energy-efficient machinery and adopting recycling practices for materials. Furthermore, companies are encouraged to collaborate with suppliers who prioritize sustainable sourcing. This not only aligns with global trends but also meets consumer expectations for transparency and responsibility in production.

Innovations are pivotal in driving this shift. For instance, incorporating bioplastics in wire harness compositions has shown promise, as they degrade more efficiently than traditional materials. Reports indicate that such advancements could support a 25% reduction in raw material waste by 2025, creating a more circular economy within the industry.

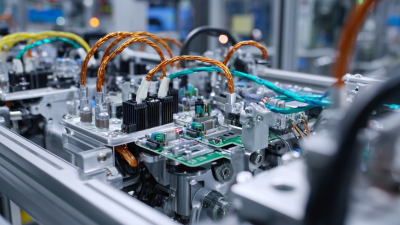

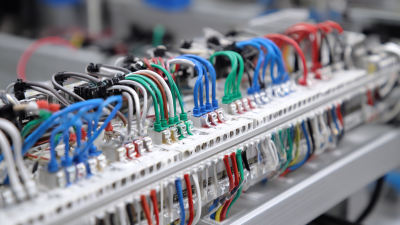

Material Innovations in Wire Harness Design: Enhancing Durability and Performance

The wire harness manufacturing industry is witnessing a significant transformation driven by material innovations aimed at enhancing durability and performance. One of the most pressing areas of focus is the integration of sustainable materials, which not only addresses environmental concerns but also improves the efficacy of wire harnesses. Advanced composite materials are increasingly being utilized, offering lighter weight and better resistance to harsh conditions, which is essential for applications in renewable energy sectors. These innovations are crucial as they support the need for robust and resilient wiring solutions in environments that demand high performance, such as solar panels and wind turbines.

Moreover, the wiring innovation propelled by the growing demand for electric public transportation, particularly in the buses and coaches market, is set to fuel unprecedented growth. With a projected compound annual growth rate of 6.0%, reaching an estimated value of USD 1.5 billion by 2035, the focus on effective wire harness solutions is paramount. Manufacturers are emphasizing the design of harnesses that not only support the complexity of electric systems but also ensure utmost safety and reliability. This shift aligns with the broader trend of adopting renewable energy solutions, showcasing how wire harness innovations are integral to the evolution of sustainable transportation technologies.

Customization and Flexibility: Meeting Diverse Industry Needs in Wire Harness Solutions

In the rapidly evolving world of wire harness manufacturing, customization and flexibility have become essential to meet the diverse needs of various industries. As companies seek solutions tailored to their specific requirements, manufacturers must adapt their processes to offer modular designs, adjustable configurations, and faster turnaround times. This trend not only enhances customer satisfaction but also allows businesses to stay competitive in an increasingly dynamic market.

**Tips for Achieving Customization in Wire Harness Manufacturing:**

1. Leverage computer-aided design (CAD) software to create detailed models that can be easily modified based on client specifications.

2. Invest in flexible manufacturing systems that can handle small to medium production runs efficiently, enabling quicker adjustments to designs.

3. Focus on strong supplier relationships to ensure access to a variety of materials for different applications and to support rapid prototyping.

As manufacturers embrace these innovations, the ability to create bespoke wire harness solutions will shape the future of the industry, allowing for increased efficiency and a better alignment with the market’s evolving demands. By prioritizing customization and flexibility, companies can better serve their clients while driving forward advancements in manufacturing technology.

Emerging Technologies: The Role of 3D Printing in Wire Harness Creation and Prototyping

The wire harness manufacturing industry is undergoing a significant transformation due to the emergence of 3D printing technologies. This innovative approach allows manufacturers to design and prototype complex wire harnesses with enhanced precision and speed. By utilizing 3D printing, companies can easily create prototypes that are not only lightweight but also customizable, ensuring that they meet the specific needs of various applications. This shift not only reduces the production timeline but also cuts down on material waste, making it an environmentally friendly alternative.

Tips: When incorporating 3D printing into your wire harness projects, consider investing in high-quality printers that can handle diverse materials. Additionally, utilizing software that specializes in 3D modeling can significantly streamline the design process, allowing a more iterative approach to prototyping.

As the industry continues to evolve, the integration of 3D printing technologies is likely to pave the way for further innovations in wire harness manufacturing. Companies adapting to these advancements will find themselves better equipped to deliver efficient and effective solutions, responding to the challenges of a rapidly changing market. Embracing these emerging technologies today will be pivotal for future competitiveness.

Tips: Stay updated on the latest advancements in 3D printing materials and techniques, as these innovations can enhance the durability and functionality of your wire harness designs. Networking with industry professionals can also provide insights into best practices and emerging trends.

Related Posts

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

Exploring Innovations in Wire Harness Manufacturing for the Future of Automotive Technology

-

How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction

-

Harness Manufacturing Innovations at China Import and Export Fair in 2025

-

What is Wire Harness Assembly and Its Impact on Electronics Industry Efficiency

-

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing