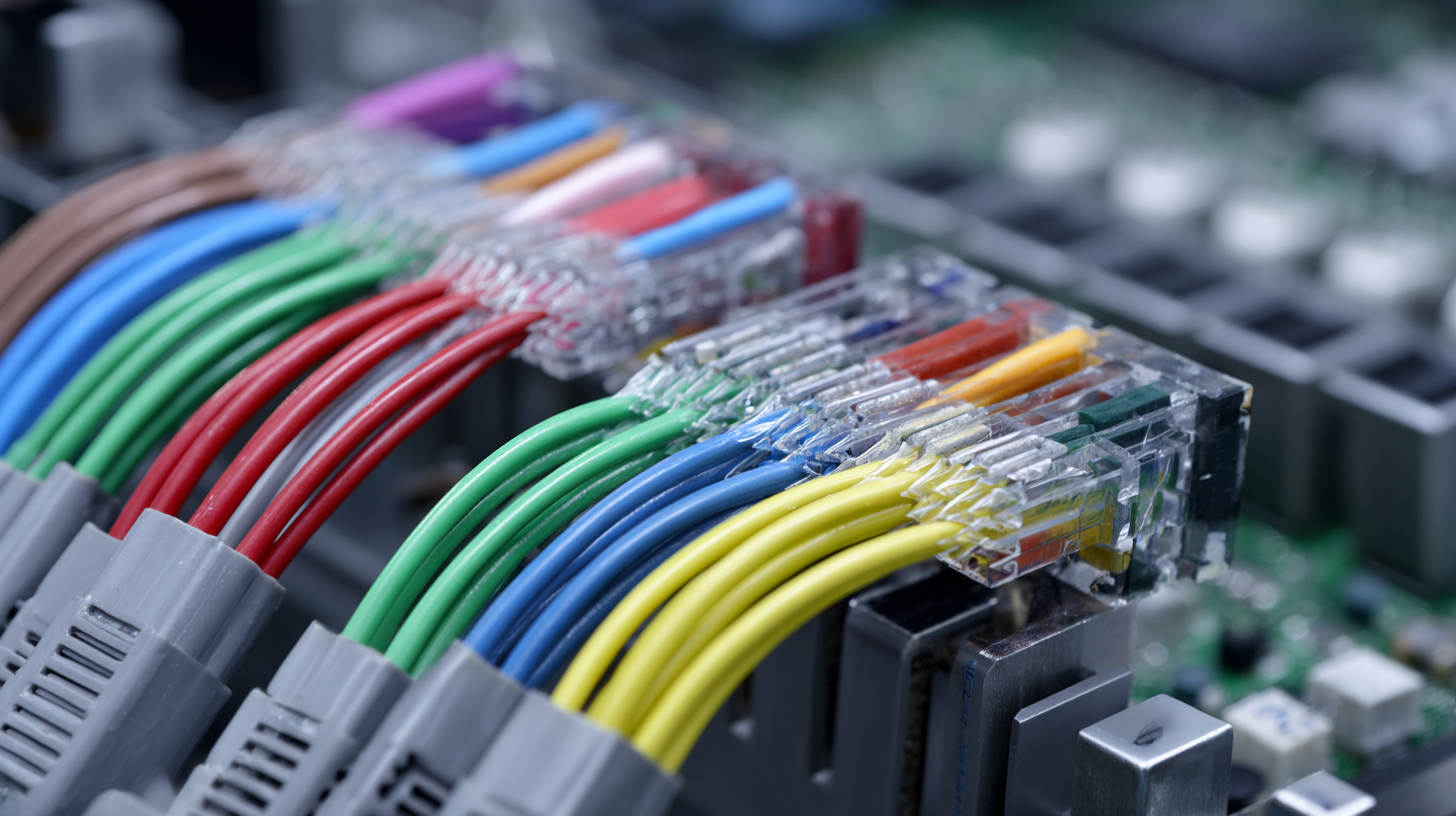

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

In the rapidly evolving landscape of the electronics industry, the sourcing of premium electronic wire harnesses has emerged as a critical component for manufacturing efficiency and product reliability. According to a report by MarketsandMarkets, the global wire harness market is projected to reach approximately $74 billion by 2025, with a compound annual growth rate (CAGR) of over 6%. China's dominance in this sector is underscored by its advanced manufacturing capabilities and stringent quality control measures, positioning it as a leading supplier for companies worldwide. This blog will explore how international businesses can effectively navigate the complexities of global sourcing while leveraging China's superior quality standards to enhance their own production processes. By understanding the nuances of sourcing electronic wire harnesses, manufacturers can ensure the delivery of high-quality products that meet the ever-increasing demands of the global market.

The Rise of China's Electronic Wire Harness Manufacturing in Global Markets

The global electronic wire harness manufacturing industry is witnessing a significant shift, with China emerging as a powerhouse in this sector. According to recent market analyses, the global railway wiring harness market was valued at approximately $3.92 billion in 2024 and is expected to grow to $6.64 billion by the end of the decade. This surge is indicative of the rising demand for efficient and high-quality wiring solutions, particularly in the transportation sector, where reliability is paramount.

Moreover, the cable assembly market is also on an upward trajectory, with a valuation of $178.6 billion in 2024, projected to expand at a compound annual growth rate (CAGR) of 6.2%, reaching an impressive $322.6 billion by 2034. This growth can be attributed to the increasing complexities of electronic systems across various industries, including automotive, telecommunications, and consumer electronics.

As Chinese manufacturers continue to refine their production processes and enhance quality controls, they are not only capturing a larger share of the global market but also setting new standards for excellence in electronic wire harness manufacturing.

Innovative Technologies Driving Quality in Chinese Wire Harness Production

The landscape of premium electronic wire harness production is rapidly evolving, driven primarily by innovative technologies embraced by Chinese manufacturers. According to a recent report from MarketsandMarkets, the global wire harness market is expected to reach $270 billion by 2025, with a significant contribution coming from China's advanced manufacturing capabilities. This substantial growth is largely attributed to the integration of automated production processes, which enhance precision and efficiency while reducing human error.

Chinese manufacturers are increasingly adopting cutting-edge technologies such as AI and IoT to monitor and optimize production lines in real time. A study by Research and Markets highlights that over 60% of wire harness manufacturers in China are investing in smart factory solutions, resulting in a 20% boost in productivity and a marked improvement in quality control. These technologies not only streamline operations but also ensure adherence to international quality standards, thereby solidifying China's reputation as a leader in the premium segment of the wire harness market. With these advancements, Chinese wire harnesses are not just competing on price but are also setting new benchmarks for quality in the global arena.

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

| Dimension | Value |

|---|---|

| Production Capacity (units/month) | 1,500,000 |

| Quality Assurance Rating (out of 100) | 95 |

| Average Lead Time (days) | 15 |

| Technical Innovation Index | 88 |

| Materials Used (% | Copper 70%, Aluminum 20%, Others 10% |

| Compliance Standards Met | ISO 9001, IPC/WHMA-A-620 |

| Export Ratio (%) | 65 |

Comparative Analysis: China vs. Other Regions in Premium Wire Harnesses

The global market for premium electronic wire harnesses is witnessing significant growth, particularly in the railway and automotive sectors. As of 2024, the railway wiring harness market was valued at approximately $3.92 billion, with projections indicating an increase to $4.15 billion in 2025 and reaching $6.64 billion by 2032. This growth underscores the rising demand for high-quality wiring solutions essential for safety and reliability in modern transportation systems.

When examining the comparative landscape of wire harness production, China stands out for its superior quality and competitive pricing. The country has increasingly positioned itself as a leader in the production of premium wiring harnesses, leveraging advanced manufacturing technologies and stringent quality control measures. In contrast, other regions struggle to match this combination of quality and cost-effectiveness, thereby limiting their market share in the increasingly competitive global environment. The automotive wiring harness market, for instance, is projected to experience substantial growth, with important segments including electric wires, connectors, and terminals that are critical to vehicle performance and safety.

Future Trends: Sustainability and Efficiency in Electronic Wire Harness Sourcing

As the global demand for sustainable transportation solutions continues to rise, the focus on electronic wire harnesses has intensified, particularly within the evolving landscape of electric vertical take-off and landing (eVTOL) technology. These innovative aircraft are designed to meet the increasing expectations for eco-friendly practices, driving the need for high-quality, efficient electronic wire harnesses that support sophisticated electrification processes. The shift toward sustainability is not just a trend but a necessity in aviation, paving the way for suppliers who prioritize quality and eco-conscious materials in their offerings.

In line with this movement, the automotive industry is also witnessing a significant transformation with the adoption of lightweight materials such as tin-plated copper and aluminum for wire harnesses. These materials provide not only durability but also enhanced efficiency, crucial for the performance of electric vehicles (EVs). The demand for advanced electronic architectures in software-defined cars further emphasizes the need for high-performance wire harnesses, which can seamlessly integrate with the latest technological innovations. As automotive sales, particularly in the EV sector, soar, so too does the importance of adopting sustainable practices and materials in electronic wire harness sourcing.

Key Industries Benefiting from High-Quality Wire Harness Solutions in China

In today's rapidly evolving technological landscape, the global sourcing of premium electronic wire harnesses presents a pivotal opportunity for various key industries. China's prowess in manufacturing high-quality wire harness solutions has attracted significant attention, particularly as businesses increasingly embrace artificial intelligence. This synergy not only enhances product performance but also drives efficiency in sectors like commercial aerospace, automotive, and consumer electronics.

Industries that leverage China's advanced wire harness technologies are witnessing substantial benefits. The intricate designs and superior quality of these harnesses play a crucial role in enhancing the reliability and safety of high-tech applications. As the demand for more sophisticated electronic systems grows, the emphasis on sourcing from regions with proven quality—such as China—will likely continue to expand. This focus not only contributes to the advancement of technology but also supports the broader goals of economic development, aligning with the ongoing initiatives to promote high-quality growth within the country.

Global Sourcing of Premium Electronic Wire Harnesses: Quality Comparison

This chart illustrates the quality ratings of wire harness solutions sourced from different countries. The rating is based on various factors including material quality, manufacturing precision, and durability.