Why is Cable Assembly Wire Harness Important for Modern Electronics?

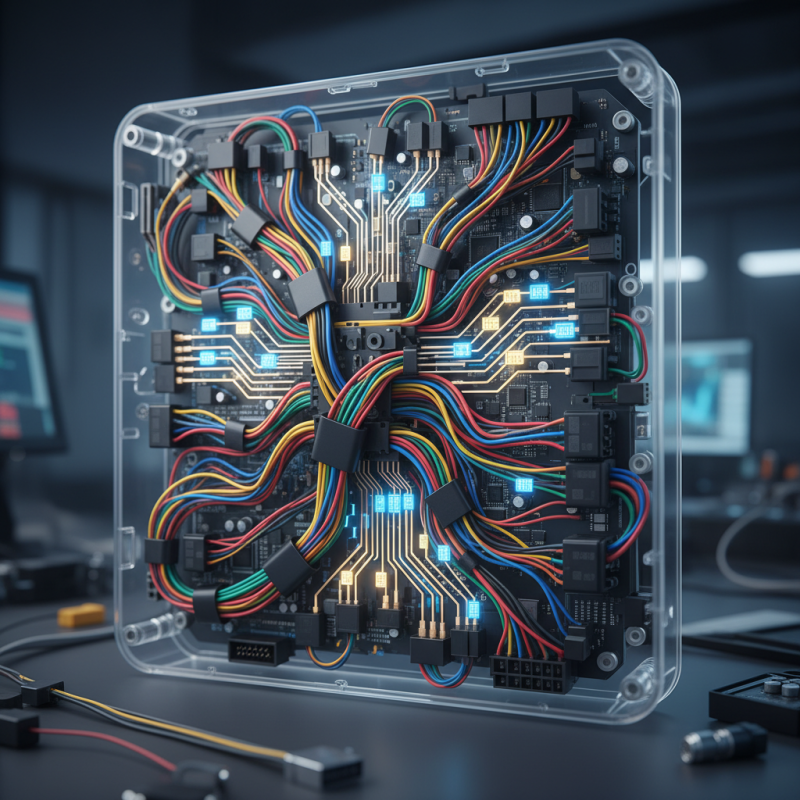

In the world of modern electronics, the importance of a cable assembly wire harness cannot be overstated. This integral component serves as the nervous system of electronic devices. It connects various parts, ensuring power and data flow seamlessly. Without it, devices would struggle to function efficiently.

Cable assembly wire harnesses come in diverse shapes and sizes. Each design addresses specific needs within electronic applications. Many may overlook their complexity, but they are crucial in reducing assembly time and minimizing errors. When crafted properly, they enhance durability and reliability.

However, not all cable assembly wire harnesses are created equal. Poor design can lead to malfunctions or even safety hazards. Companies must invest time and resources to ensure high-quality harnesses. Mistakes in this area can result in delays and increased costs. Reflecting on these factors reveals the vital role that cable assembly wire harnesses play in our daily technology.

Understanding the Basics of Cable Assembly Wire Harness

Cable assembly wire harnesses are crucial in modern electronics. These components integrate various wires and cables, ensuring reliable connections across devices. A typical wire harness can reduce assembly time by up to 30%. Efficiency matters, especially as devices grow more complex.

Understanding cable assembly is key. Each harness must accommodate specific voltages and currents. For instance, aerospace applications require robust materials to withstand harsh conditions. Statistics show that improperly assembled harnesses account for nearly 25% of failures in electronic devices. Therefore, attention to detail is non-negotiable.

**Tips:** Choose materials wisely. Use heat-resistant and durable plastics for longevity. Regularly inspect your harnesses for wear and tear to prevent malfunctions. Planning and testing can save significant costs in the long run. Keep in mind, overlooking even minor flaws can lead to major issues. It's essential to continuously reflect on assembly processes for improvements.

Key Functions of Cable Assembly Wire Harness in Electronics

Cable assembly wire harness plays a pivotal role in modern electronics. It serves multiple key functions that enhance performance and reliability. First, it helps streamline electrical connections. By minimizing the need for lengthy wiring, it reduces signal loss and interference. According to a recent industry report, efficient wire harness designs can decrease assembly time by up to 30%. This not only boosts productivity, but also cuts down on labor costs.

Another significant function is the protection of electrical components. Wire harnesses shield cables from environmental factors like moisture and dust. For instance, in automotive applications, a robust harness can withstand harsh conditions. Studies show that around 65% of electronic failures are related to poor connections. A well-designed wire harness mitigates such risks. However, not all harnesses are created equal. Some designers overlook critical factors like heat dissipation.

Moreover, wire harnesses enable easier repairs and replacements. They simplify troubleshooting processes, allowing technicians to identify issues faster. Yet, in some cases, cable assemblies can become tangled, making maintenance challenging. An estimated 20% of maintenance time can be wasted on cable management. This indicates a need for better design and planning in future projects.

Why is Cable Assembly Wire Harness Important for Modern Electronics? - Key Functions of Cable Assembly Wire Harness in Electronics

| Function | Description | Benefits |

|---|---|---|

| Signal Transmission | Transfers electrical signals between components in electronic devices. | Ensures efficient communication within the device. |

| Power Distribution | Distributes electrical power from the source to various components. | Critical for device functionality and energy efficiency. |

| Protection | Encases wires to protect them from physical damage and environmental factors. | Enhances durability and longevity of electronic devices. |

| Organization | Organizes and streamlines the wiring in electronic assemblies. | Facilitates easier assembly and maintenance. |

| Customization | Allows for tailor-made solutions specific to device requirements. | Enhances performance by meeting unique application needs. |

Advantages of Using Wire Harnesses in Modern Devices

Wire harnesses play a crucial role in modern electronics. They bundle multiple wires and connectors into a single unit. This organization simplifies the manufacturing process. It also makes installations faster and easier.

Devices with wire harnesses are often more reliable. A neatly organized bundle reduces the chance of errors. It minimizes potential damage during assembly. However, poor design can still lead to issues. Not all wire harnesses accommodate future upgrades.

Efficiency is another key benefit. With fewer loose wires, troubleshooting becomes simpler. Technicians can pinpoint problems quickly. Yet, if the harness is too rigid, flexibility may be lost. Balance is vital. Good wire harness design not only enhances performance but also considers the need for adaptability.

Importance of Cable Assembly Wire Harness in Modern Electronics

Common Applications of Cable Assemblies in the Industry

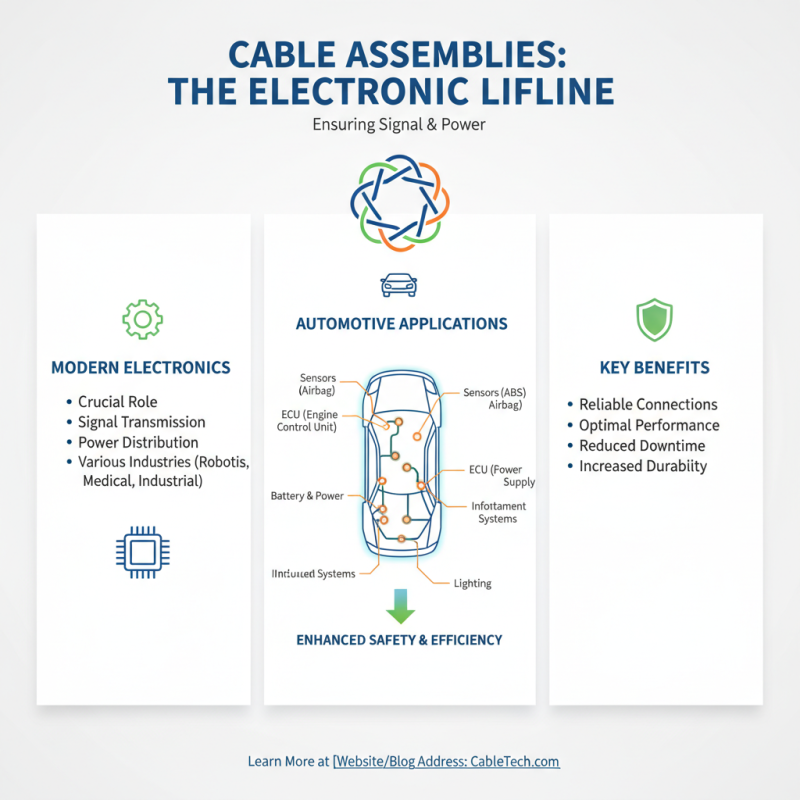

Cable assemblies play a crucial role in modern electronics. They are used extensively in various industries, ensuring proper signal transmission and power distribution. In automotive applications, harnesses connect critical components like sensors and power supplies. These connections enhance safety and efficiency in vehicles.

In the medical sector, cable assemblies are vital for devices such as MRI machines. These assemblies ensure the reliable operation of life-saving equipment. Additionally, the consumer electronics industry relies on cable harnesses for complex devices like smartphones. Each connection impacts performance and user experience.

Despite their importance, cable assemblies can present challenges. Design flaws may lead to signal loss or failures. Manufacturers must prioritize quality to avoid costly repairs. The need for precise craftsmanship cannot be understated. Continuous improvements in design and testing processes are essential for enhanced reliability. Each assembly must be carefully evaluated to meet strict standards.

Future Trends in Cable Assembly Technology and Its Impact

The future of cable assembly technology is dynamic and evolving. As the electronics industry grows, so does the need for reliable cable assembly wire harnesses. According to a recent industry report, the global market for cable assemblies is projected to reach $250 billion by 2026, driven by advancements in automotive and consumer electronics. These sectors demand higher efficiency, making cable harness designs essential for performance.

Trends indicate a shift toward automation in cable assembly production. Automated processes enhance precision and reduce human errors, which are significant factors in manufacturing. However, some challenges persist. Many companies grapple with integrating new technologies while ensuring quality control. A 2022 study found that 40% of manufacturers face difficulties in adapting existing workflows. Additionally, the growing emphasis on sustainability urges firms to explore eco-friendly materials, potentially complicating the transition to new designs.

Increased connectivity through IoT devices also plays a crucial role. The rise of smart technology requires complex wiring systems that can handle data and power simultaneously. Reports suggest that over 50 billion IoT devices will be in use by 2030. This surge creates opportunities but also raises questions about scalability and reliability in cable assemblies. The industry must innovate continuously, keeping pace with shrinking device sizes, without compromising on effectiveness.

Related Posts

-

What is Wire Harness Assembly and Its Impact on Electronics Industry Efficiency

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

Exploring the Future of Wire Harness Manufacturing: Innovations That Are Shaping the Industry

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency