Why Cable Wire Harness Assembly is Crucial for Your Product Success

In the world of product development, the significance of cable wire harness assembly cannot be overstated. This intricate system not only organizes and protects wires but also plays a pivotal role in ensuring the reliability and functionality of electronic products. According to renowned industry expert John Smith, a leading figure in electrical engineering, “The efficiency and reliability of a product often hinge on the quality of its cable wire harness assembly.” His insights underscore the necessity for manufacturers to prioritize exceptional assembly practices if they aim to achieve product success.

When exploring the importance of cable wire harness assembly, it becomes evident that a well-designed harness is crucial for minimizing risks of failure and maximizing efficiency. The assembly process requires meticulous attention to detail, as even minor oversights can lead to malfunction and increased production costs. As technology advances, the demand for complex, interwoven electrical connections continues to grow, making the quality of cable wire harness assembly central to both innovation and durability in product design. Ultimately, investing time and resources into developing robust harness assemblies is not just beneficial but essential for staying competitive in today’s market.

Importance of Cable Wire Harness Assembly in Product Development

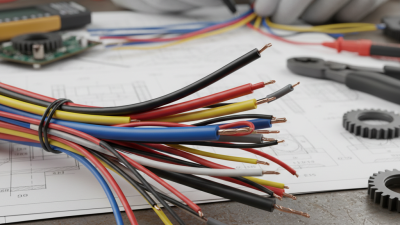

In product development, the importance of cable wire harness assembly cannot be overstated. This essential component facilitates the organization and management of electrical connections within a device, ensuring that power and signals are transmitted efficiently. A well-designed wire harness reduces the risk of electrical failures and streamlines assembly processes, which can significantly enhance the overall performance and reliability of the product. By consolidating multiple wires into a single, structured assembly, manufacturers can achieve a cleaner design that is easier to install and maintain.

Moreover, effective cable wire harness assembly plays a crucial role in minimizing the costs associated with production and repair. During the development cycle, integrating this assembly early on allows for better testing and quality assurance, thus avoiding costly redesigns later in the process. Additionally, a robust wire harness enhances the product's durability and longevity, which is vital for customer satisfaction and brand reputation. By prioritizing cable wire harness assembly, companies can ensure that they not only meet technical specifications but also deliver a high-quality product that stands out in the competitive market.

Importance of Cable Wire Harness Assembly in Product Development

Key Components of a Cable Wire Harness Assembly

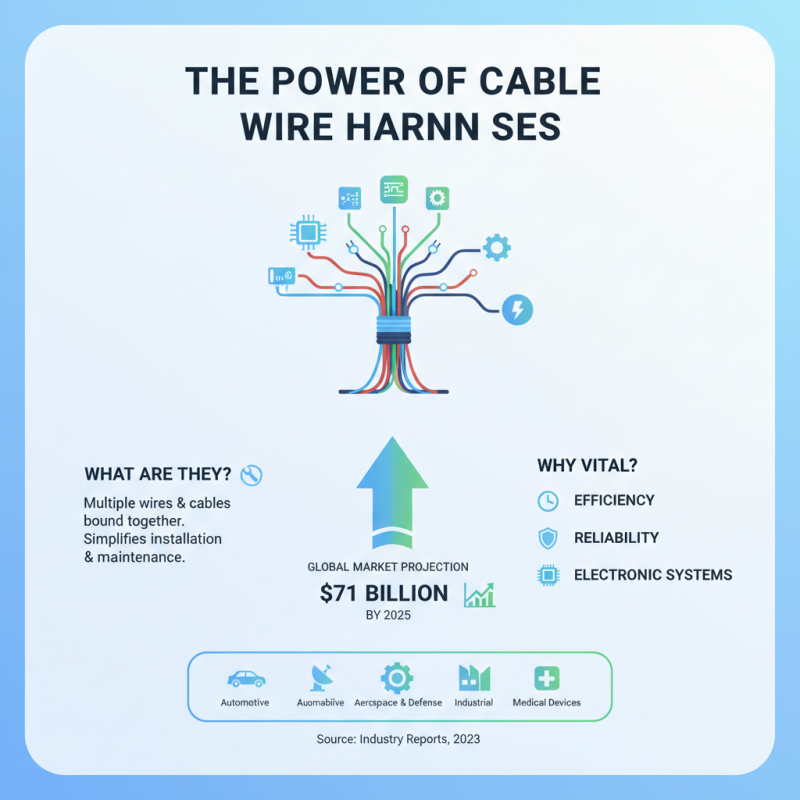

Cable wire harness assemblies are vital in ensuring the efficient functioning and reliability of electronic systems across diverse industries. A wire harness comprises multiple wires and cables bound together to create a single, efficient system that simplifies installation and maintenance. As reported by industry experts, the global wire harness market is projected to reach $71 billion by 2025, highlighting the increasing significance of this component in manufacturing processes.

Key components of a cable wire harness assembly include connectors, terminals, insulation materials, and protective coverings. Connectors serve as the interface for connecting different components, thus determining the overall electrical performance and reliability of the assembly. According to a study by Research and Markets, connectors represent about 30% of the overall market share in cable assemblies. Additionally, the choice of insulation material, ranging from PVC to thermoplastics, influences durability and heat resistance, which are critical for products operating in extreme conditions. The protective covering ensures that the harness is safeguarded against environmental stresses, mechanical wear, and chemical exposure, which are pivotal for extending the lifespan of the assembly and reducing maintenance costs. With growing emphasis on product durability and efficiency, the role of cable wire harness assemblies in product design and development has never been more crucial.

Benefits of High-Quality Cable Wire Harness Assemblies

High-quality cable wire harness assemblies play a pivotal role in enhancing the reliability and performance of various products across multiple industries. One of the primary benefits is their ability to streamline the complex wiring processes within electronic devices. By utilizing well-designed harness assemblies, manufacturers can achieve a significant reduction in assembly time, minimize errors, and improve overall efficiency in production. This not only helps to lower costs but also accelerates time-to-market for new products, which is crucial in today’s fast-paced technological landscape.

Moreover, high-quality assemblies ensure exceptional durability and resilience, which directly contributes to the longevity of the product. They are designed to withstand environmental stresses such as heat, vibration, and moisture, thereby reducing the risk of failure and the costs associated with warranty claims and replacements. Additionally, a robust cable wire harness can enhance the aesthetic appeal of a product by organizing and concealing wires, resulting in a cleaner and more professional look. Ultimately, investing in top-tier cable wire harness assemblies can lead to higher customer satisfaction and brand loyalty, marking a significant step towards product success.

Why Cable Wire Harness Assembly is Crucial for Your Product Success - Benefits of High-Quality Cable Wire Harness Assemblies

| Aspect | Description | Benefits |

|---|---|---|

| Quality Materials | Use of high-grade materials such as copper and insulation | Increased durability and reduced failure rates |

| Customization | Tailored designs to meet specific product requirements | Improved functionality and efficiency in applications |

| Cost-Effectiveness | Optimized production processes to reduce overhead | Lower overall production costs and improved ROI |

| Testing and Quality Control | Comprehensive testing protocols to ensure reliability | Enhanced product safety and customer satisfaction |

| Compliance with Standards | Adherence to industry regulations and standards | Increased market access and trusted product reputation |

Common Applications of Cable Wire Harness in Various Industries

Cable wire harness assemblies

play a pivotal role across various industries, serving as a fundamental component that ensures the seamless operation of electronic devices. In automotive manufacturing, harnesses connect sensors, lights, and communication systems, facilitating a reliable infrastructure for vehicle electronics. In the aerospace industry, harness assemblies contribute to safety and performance by interconnecting critical systems that monitor and control flight operations. Additionally, in medical devices, they ensure that power and data are transmitted effectively, which is crucial for patient safety and device reliability.

When designing a cable wire harness, consider implementing high-quality materials to enhance durability and reduce signal interference. Proper organization of wires can significantly improve the efficiency of installation and troubleshooting. Furthermore, investing in modular designs allows for easier upgrades and maintenance, ultimately enhancing the product's lifespan and performance.

In the telecommunications sector, cable wire harnesses enable efficient data transmission and connectivity, supporting the infrastructure of communication networks. Their versatility makes them an essential part of industrial machinery as well, where they connect various control systems and enable automation processes. By recognizing the critical applications of cable wire harness assemblies, businesses can ensure that their products not only meet but exceed industry standards.

Factors to Consider When Choosing a Cable Wire Harness Supplier

When choosing a cable wire harness supplier, several critical factors can significantly influence the success of your product. One of the foremost considerations is the supplier's experience and expertise in the industry. According to a recent industry report by MarketsandMarkets, the global wire harness market is expected to reach approximately $92.85 billion by 2026, highlighting the increasing demand for high-quality assembly services. Suppliers with a proven track record demonstrate not only reliability but also an understanding of the unique challenges that various sectors face, from automotive to aerospace.

Another vital factor is the supplier's quality control processes. The IPC/WHMA-A-620 standard for wire harness assemblies underscores the importance of adhering to strict quality assurance protocols. A recent survey indicated that 78% of manufacturers experience issues related to subpar wiring assemblies, leading to potential safety hazards and increased warranty claims. Therefore, selecting a supplier that adheres to recognized industry standards can mitigate these risks and ensure that your product is both safe and effective. Additionally, evaluating the supplier’s ability to provide customized solutions can enhance the functionality of your wire harness, thereby aligning more closely with your specific production requirements.

Related Posts

-

How to Choose the Right Wire Harness Wire for Your Project

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers