Exploring Innovations in Wire Harness Manufacturing for the Future of Automotive Technology

The automotive industry is undergoing a transformative shift propelled by cutting-edge technologies and increased demand for efficiency and sustainability. Central to this evolution is the innovation in wire harness manufacturing, a critical component that underpins the electrical systems in vehicles. As vehicles become more sophisticated with the integration of advanced driver-assistance systems (ADAS), electric powertrains, and connectivity features, the significance of optimized wire harness design and production processes is more pronounced than ever. This exploration delves into the latest advancements and methodologies in wire harness manufacturing that not only enhance performance but also streamline production practices. By addressing the pivotal question of "Why" innovation in this field matters, we aim to uncover how these developments are shaping the future of automotive technology and contributing to the creation of safer, more efficient, and environmentally friendly vehicles.

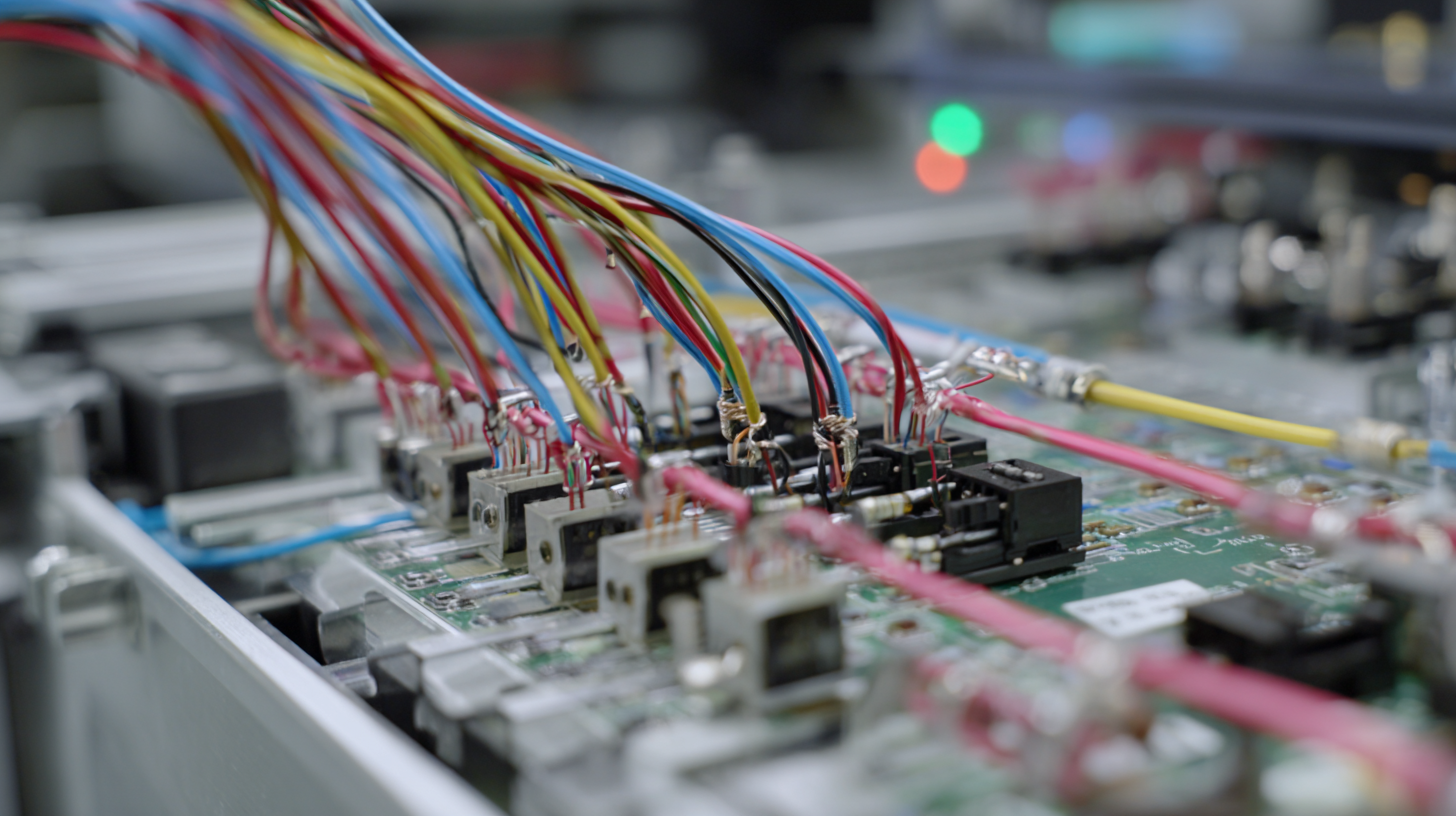

Emerging Technologies Revolutionizing Wire Harness Production in Automotive Industry

The automotive industry is rapidly evolving, and so is the technology behind wire harness manufacturing. Emerging technologies such as advanced robotics, automation, and artificial intelligence are revolutionizing production processes. These innovations not only enhance efficiency but also improve the accuracy and reliability of wire harnesses, which are critical for vehicle performance and safety. By implementing sophisticated machinery and digital twin technology, manufacturers can simulate production scenarios to optimize layout and operations before actual implementations begin.

Tips: When considering innovations in wire harness manufacturing, focus on integrating automation where possible. Evaluate the return on investment through reduced labor costs and improved throughput times. Additionally, keep an eye on emerging materials, such as lightweight composites, which can significantly enhance the performance of wire harnesses while adhering to sustainability goals.

Digital transformation is at the forefront of these advancements, enabling real-time data collection and analysis. This capability allows manufacturers to detect issues early in the production cycle, minimizing waste and rework. As electric vehicles and smart technologies become more prevalent, the demand for highly intricate and efficient wire harnesses will only grow. Staying updated with these trends will ensure competitiveness in an ever-changing market.

Tips: Make use of data analytics to forecast trends and demands accurately. Training your workforce on new technologies will also ensure that they are equipped to handle evolving production techniques effectively, thereby maximizing operational efficiency.

Integration of Smart Materials for Enhanced Performance in Wire Harnesses

The integration of smart materials in wire harness manufacturing is poised to revolutionize automotive technology by enhancing the performance, reliability, and efficiency of electrical systems in vehicles. Smart materials, known for their ability to respond dynamically to environmental changes, can significantly reduce the weight and bulk of traditional wire harnesses. This reduction not only improves fuel efficiency but also optimizes space within the vehicle, allowing for more innovative designs and features.

Moreover, the adaptability of smart materials enables wire harnesses to maintain optimal functionality under varying conditions. For instance, materials that can self-repair or adjust their properties in response to temperature fluctuations will ensure that electrical systems remain operational even in extreme climates. This resilience is crucial as vehicles increasingly rely on complex electrical systems for everything from safety features to infotainment. As automotive technology continues to advance, the incorporation of smart materials will play a vital role in meeting the growing demands for performance and sustainability in the industry.

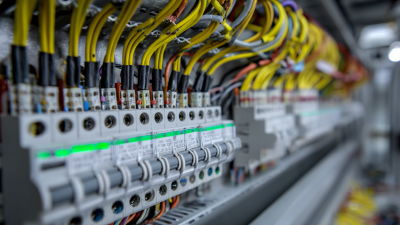

Exploring Automation and AI in Wire Harness Design and Manufacturing Processes

The automotive industry is undergoing a transformative phase, significantly influenced by automation and artificial intelligence (AI) in wire harness design and manufacturing. According to a report by MarketsandMarkets, the global automotive wire harness market is projected to reach $62.7 billion by 2025, driven by the growing demand for advanced vehicle technologies. Automation not only enhances efficiency in manufacturing processes but also ensures higher precision in wire harness assembly. AI algorithms can predict potential failures and optimize design layouts, thereby reducing material waste and minimizing costs.

**Tips:** When integrating AI into your wire harness manufacturing processes, start small by focusing on specific tasks like quality control or production scheduling. This allows for gradual adaptation without overwhelming your team. Additionally, investing in training for your workforce on new automated systems can enhance acceptance and effectiveness.

AI's role in predictive maintenance is another significant area of innovation. By analyzing data from machinery, AI can identify patterns that indicate potential issues before they become critical, ensuring a seamless production flow. As such, automakers and component manufacturers that leverage these technologies are positioned to maintain a competitive edge in the rapidly evolving market.

**Tips:** Regularly review and analyze production data. By establishing a feedback loop between design and manufacturing teams, you can continuously improve processes and enhance product quality.

Innovations in Wire Harness Manufacturing: Automation and AI Impact

Sustainability Practices: Eco-friendly Innovations in Wire Harness Manufacturing

The automotive industry is undergoing a significant transformation, with wire harness manufacturing taking center stage in the quest for sustainability. As demand for electric vehicles (EVs) and other eco-friendly technologies rises, manufacturers are shifting their focus towards innovative practices. Key trends such as the incorporation of recycled materials, efficient energy use, and the integration of advanced technologies play a crucial role in minimizing the environmental impact of wire harness production.

Tips for enhancing sustainability in wire harness manufacturing include exploring the use of biodegradable materials and implementing circular economy principles. Manufacturers should also consider investing in smart manufacturing systems that leverage real-time data and artificial intelligence to optimize resource use and reduce waste.

Embracing sustainability not only benefits the environment but also enhances brand reputation and compliance with increasing regulatory standards. As the industry pivots towards greener solutions, stakeholders must remain informed about advancements in sustainable practices and technologies to stay competitive and contribute to a more sustainable future in automotive manufacturing.

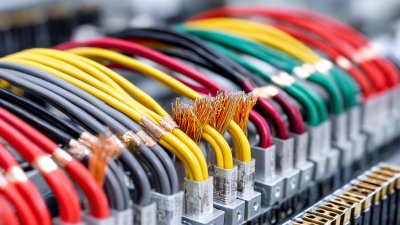

The Impact of Advanced Data Analytics on Wire Harness Production Efficiency

The automotive industry is witnessing a significant transformation due to advancements in data analytics, which play a critical role in enhancing wire harness manufacturing efficiency. By leveraging big data and machine learning algorithms, manufacturers can optimize production processes, reduce waste, and improve overall quality. Real-time data analysis allows for immediate identification of bottlenecks in the production line, enabling swift corrective actions that minimize downtime and increase output.

Moreover, predictive analytics enables manufacturers to foresee potential failures and implement proactive maintenance strategies. This approach not only extends the lifespan of equipment but also ensures that production schedules are met consistently. Furthermore, advanced data analytics facilitates better supply chain management by predicting demand trends, optimizing inventory levels, and streamlining logistics. As a result, wire harness manufacturers are empowered to produce high-quality components that meet the increasing complexity and customization demands of modern automotive technology.

Related Posts

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction

-

Harness Manufacturing Innovations at China Import and Export Fair in 2025

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

How to Choose the Right Cable Assembly Wire Harness for Your Project

-

What is the Importance of Cable Wire Harness Assembly in Modern Electronics