Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

In today's rapidly evolving technological landscape, the demand for high-quality wire harness cables has surged, driven largely by advancements in automotive, aerospace, and consumer electronics industries. According to a recent market research report by Grand View Research, the global wire harness market is projected to reach USD 80 billion by 2025, expanding at a compound annual growth rate (CAGR) of 4.8%.

This growth underscores the critical role wire harness cables play in ensuring optimal connectivity and functionality of increasingly complex electronic systems. As global buyers navigate the comprehensive landscape of sourcing wire harness cables, understanding the latest trends, quality benchmarks, and market insights becomes essential. With China's manufacturing capabilities spearheading this sector's innovation and production, it is imperative to explore the strategies that underpin the sourcing of these vital components to guarantee quality and performance in a competitive market.

Understanding Wire Harness Cables: Key Specifications You Need to Know

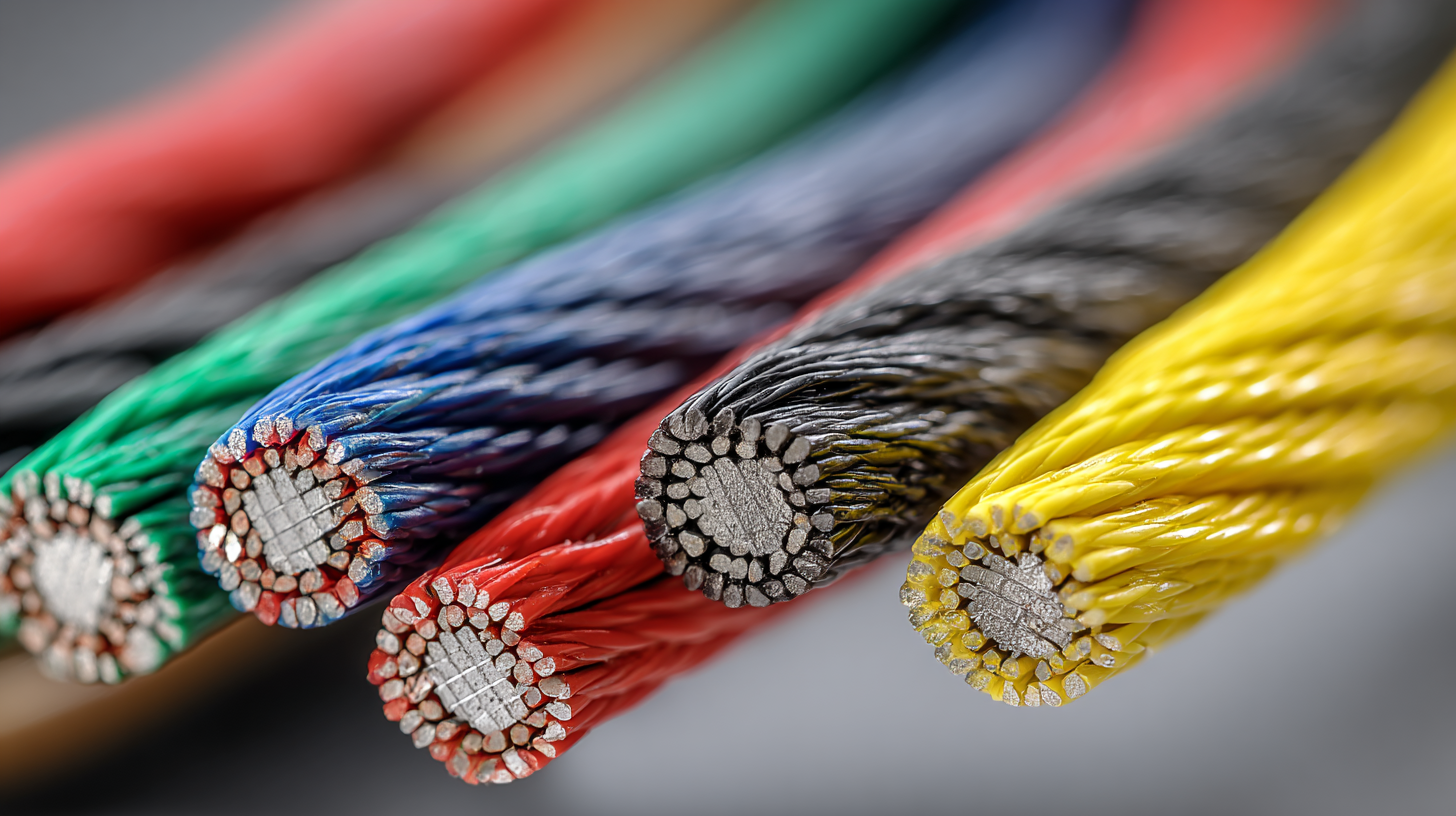

Wire harness cables play a crucial role in various industries, including automotive, aerospace, and consumer electronics. Understanding the key specifications is essential for global buyers to ensure optimal performance and reliability. A wire harness typically consists of bundles of wires, connectors, terminals, and other components, carefully assembled to facilitate electrical connections.

According to a recent market research report by Fortune Business Insights, the global wire harness market is projected to reach USD 78.71 billion by 2025, growing at a CAGR of 6.4%. This growth highlights the increasing demand for high-quality wire harnesses that meet rigorous specifications.

Wire harness cables play a crucial role in various industries, including automotive, aerospace, and consumer electronics. Understanding the key specifications is essential for global buyers to ensure optimal performance and reliability. A wire harness typically consists of bundles of wires, connectors, terminals, and other components, carefully assembled to facilitate electrical connections.

According to a recent market research report by Fortune Business Insights, the global wire harness market is projected to reach USD 78.71 billion by 2025, growing at a CAGR of 6.4%. This growth highlights the increasing demand for high-quality wire harnesses that meet rigorous specifications.

When evaluating wire harness cables, several key specifications must be considered. The gauge of the wire, for example, influences the amount of current that can safely pass through without overheating. Industry standards such as AWG (American Wire Gauge) provide a framework for selecting the appropriate wire size for specific applications. Additionally, insulation materials—ranging from PVC to XLPE—affect the wire's resistance to environmental factors like temperature and moisture. Furthermore, certification from organizations such as UL (Underwriters Laboratories) adds credibility to the product, ensuring compliance with safety standards. Understanding these specifications enables buyers to make informed decisions and select wire harness cables that align with their project requirements.

Essential Factors for Selecting the Right Wire Harness for Your Project

When selecting the right wire harness for your project, it's crucial to consider several essential factors that can greatly impact both performance and reliability. First and foremost, understanding your specific application requirements is key. This includes analyzing the voltage, current, and environmental conditions in which the wire harness will operate. By aligning these parameters with your project needs, you can prevent many common failures associated with improper specifications.

Another important tip is to evaluate the materials used in the wire harness construction. Different materials can offer various advantages, such as improved resilience to heat, moisture, and chemicals. Ensuring that the insulation and wire materials are suitable for your environment will enhance durability and performance. Additionally, pay special attention to the quality of connectors as they play a pivotal role in maintaining a secure and efficient connection.

Lastly, don't underestimate the significance of supplier reputation and experience. A reliable supplier who understands the latest industry trends can provide valuable insights and recommendations tailored to your project. Researching potential suppliers and reading customer reviews can help you identify who offers the best products and services, ensuring you make an informed decision for your wire harness needs.

Current Trends in Wire Harness Production and Usage: A Global Overview

The wire harness industry has witnessed significant transformations recently, driven by technological advancements and changing market demands. According to a report by MarketsandMarkets, the global wire harness market is projected to grow from $59.3 billion in 2021 to $74.8 billion by 2026, at a compound annual growth rate (CAGR) of 4.8%. This growth is being propelled by the increasing use of wire harnesses in various sectors, especially in the automotive and aerospace industries, where their efficiency in managing electrical distributions becomes crucial as vehicles become more electronic and automated.

Furthermore, trends reveal a shift towards more sustainable practices in wire harness production. A report by ResearchAndMarkets highlights that manufacturers are increasingly adopting eco-friendly materials and processes, aiming to reduce the carbon footprint of their products. The push for electric vehicles (EVs) is also a significant driver, with demand for lightweight, high-performance wire harnesses rising to support the needs of EV systems. The integration of smart technologies, such as IoT and AI, in wire harnesses is also on the rise, providing enhanced functionalities and connectivity, thus catering to the evolving demands of global buyers seeking innovation and efficiency.

Best Practices for Sourcing Wire Harness Cables from Reliable Suppliers

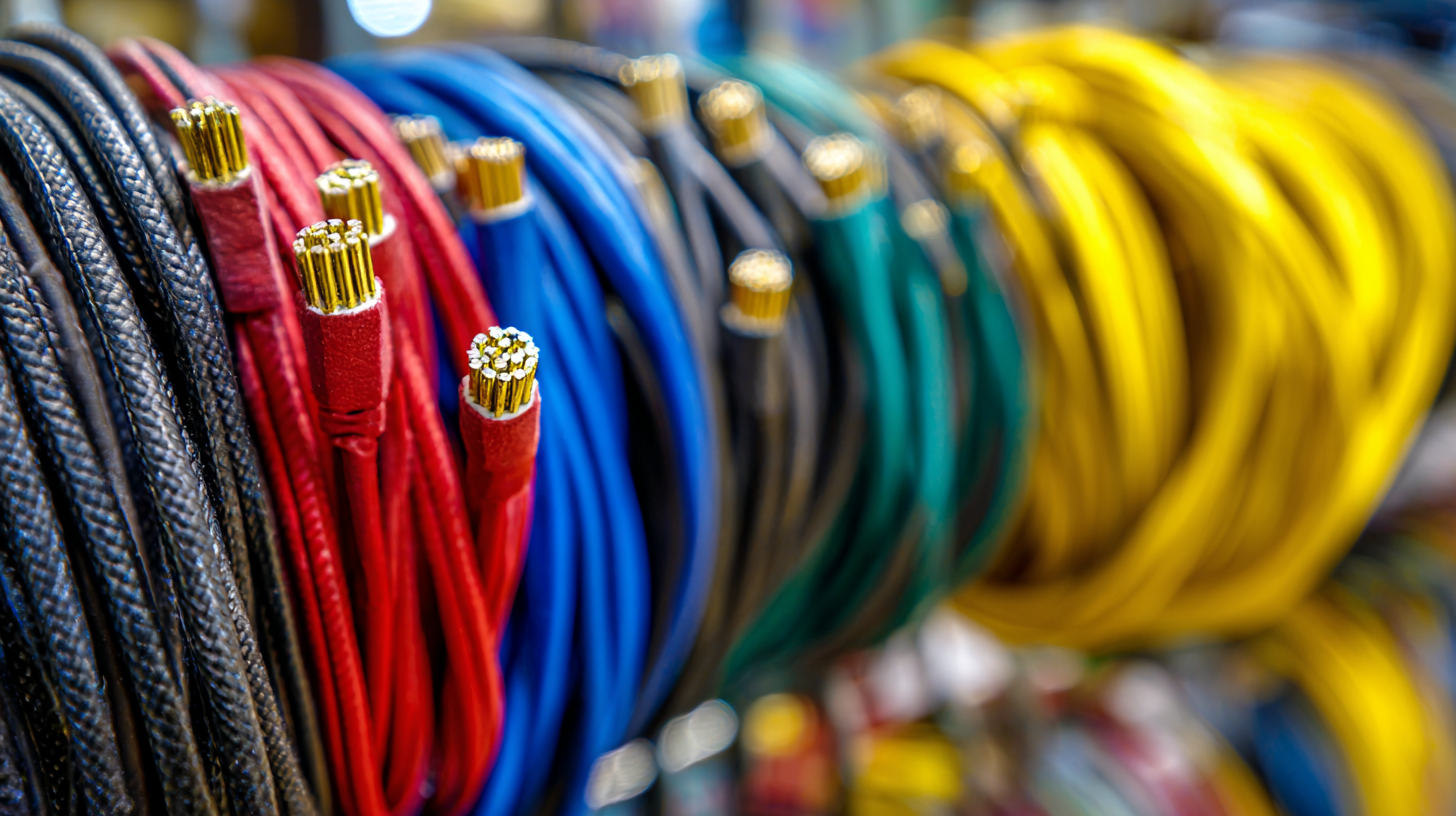

When sourcing wire harness cables, partnering with reliable suppliers is crucial to ensure quality and longevity. One of the best practices is to conduct thorough research on potential suppliers. Look for manufacturers with a proven track record in the industry, positive customer reviews, and relevant certifications. A supplier’s ability to comply with international standards can indicate their commitment to quality. Engaging in direct communication with suppliers can also provide insights into their manufacturing processes and quality control measures.

Another essential practice is to establish clear specifications for the wire harness cables you need. This includes details about the materials, dimensions, and performance requirements. By providing comprehensive specifications, you can facilitate a more accurate quotation process and reduce the chances of misunderstandings after the order is placed. Additionally, consider sourcing samples before making bulk purchases. This allows you to evaluate the quality and compatibility of the cables with your applications, ensuring that you make informed decisions that meet your expectations.

Ultimate Guide to Sourcing the Best Wire Harness Cables

| Sourcing Consideration | Details | Best Practices |

|---|---|---|

| Supplier Reliability | Check reputation through reviews and references. | Use verified platforms for supplier selection. |

| Material Quality | Ensure cables meet industry standards. | Request material certifications. |

| Customization Options | Ability to tailor cables to specific needs. | Discuss customization during initial quotes. |

| Lead Time | Expected time from order to delivery. | Establish clear timelines and penalties. |

| Cost Competitiveness | Price comparison among multiple suppliers. | Seek quotes from at least three suppliers. |

| Compliance and Regulations | Understand regional safety and environmental regulations. | Verify compliance certificates from suppliers. |

| Customer Support | Availability of technical and after-sales support. | Engage with support teams before purchasing. |

Navigating Challenges in the Wire Harness Market: Insights for Global Buyers

Navigating the ever-evolving wire harness market presents challenges that require strategic insights and informed decision-making from global buyers. According to a recent report by Research and Markets, the global wire harness market is projected to reach $80 billion by 2027, growing at a CAGR of 6.1%. This growth is driven by increased demand from the automotive and aerospace sectors, as well as the burgeoning industries of renewable energy and electric vehicles. As buyers, understanding these trends can position companies favorably against competitors.

However, challenges such as fluctuating material costs and supply chain disruptions have emerged. A survey by the Global Supply Chain Institute indicates that 75% of sourcing managers faced delays due to logistical issues in 2022. Buyers must adopt agile sourcing strategies and focus on building strong relationships with manufacturers to mitigate risks. Additionally, leveraging data analytics to monitor market trends and price fluctuations can help buyers make more informed procurement decisions, ultimately leading to better profitability and operational efficiency in a competitive landscape.