Top 10 Benefits of Using Wire Harness Wire for Your Electrical Projects

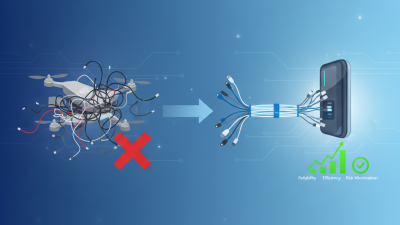

In the realm of electrical projects, efficiency and reliability are paramount. One of the key elements that can significantly enhance the performance of such projects is the use of wire harness wire. This versatile solution offers a multitude of advantages that cater to both professionals and DIY enthusiasts alike. From providing a structured approach to wiring to ensuring superior signal transmission, wire harness wire is essential for achieving seamless connectivity in any electrical application.

Utilizing wire harness wire not only streamlines the assembly process but also minimizes the risk of errors during installation. Its organized design allows for easier troubleshooting and maintenance, ultimately saving time and resources. Additionally, ample protection against wear and tear contributes to the longevity of the electrical systems being implemented. With these benefits in mind, it's clear that incorporating wire harness wire into your projects is a strategic choice that can lead to enhanced efficiency and durability in your electrical endeavors.

Key Advantages of Wire Harness Wire in Electrical Applications

When it comes to electrical applications, wire harness wire offers a range of advantages that optimize performance and enhance reliability. One of the key benefits is organized wiring management. By using wire harnesses, multiple wires can be bundled together, reducing clutter and making installations cleaner and easier to manage. This organization not only saves time during assembly but also simplifies maintenance and troubleshooting, as each wire is easily identifiable and accessible.

Another significant advantage is the increased durability and protection for the wires themselves. Wire harnessing typically involves insulation and sheathing that guard against environmental factors such as moisture, heat, and chemical exposure. This protective layer minimizes the risk of short circuits and damage, leading to longer-lasting electrical systems. Additionally, the flexibility in design allows for customization to meet specific project needs, whether it’s for automotive, industrial, or consumer electronics applications, ensuring that projects can adapt to various operational demands while maintaining high safety standards.

Top 10 Benefits of Using Wire Harness Wire for Your Electrical Projects

| Benefit | Description |

|---|---|

| Improved Organization | Wire harnesses keep cables organized, minimizing the risk of confusion and errors during assembly. |

| Enhanced Safety | Reducing exposed wires decreases the likelihood of electrical shorts and hazards, improving safety. |

| Cost Efficiency | Using wire harnesses can lower labor costs and reduce installation time compared to traditional wiring. |

| Simplified Repairs | In the event of a failure, wire harnesses make it easier to identify and replace faulty sections. |

| Flexibility | Wire harness designs can be customized to suit specific application requirements and layouts. |

| Robustness | Harnesses protect wiring from environmental elements, mechanical stress, and wear, enhancing durability. |

| Space Saving | Wire harnesses optimize space usage, allowing for more compact electrical designs. |

| Mass Production | Wire harnesses are ideal for mass production, offering consistent quality and reducing production time. |

| Better Performance | Properly engineered wire harnesses can improve signal integrity and power distribution. |

| Aesthetic Appeal | Well-designed wire harnesses enhance the visual appearance of electrical setups, making them more appealing. |

Enhanced Safety Features of Using Wire Harness Wire

When working on electrical projects, safety is a paramount consideration. Utilizing wire harness wire can significantly enhance safety features in various applications. One of the core benefits of wire harness wiring is its robust insulation, which minimizes the risk of short circuits and electrical shocks. This insulation protects both the wiring itself and the end user, especially in environments prone to moisture or other hazards. The structured design of wire harnesses also ensures that wires are organized and secured, preventing exposure to elements that could cause damage or malfunction.

Another critical aspect is the alleviation of potential fire hazards. Wire harnesses are typically designed to withstand higher temperatures and have fire-retardant properties. By effectively managing heat dissipation and reducing the chances of overheating, wire harnesses play a crucial role in safeguarding electronic devices and their users. Furthermore, the use of wire harnesses simplifies troubleshooting and maintenance, allowing for easier identification of issues without risking accidental damage or unsafe handling of loose wires.

Overall, the clear advantages of using wire harness wire reinforce its importance in ensuring safety and reliability in electrical projects.

Improved Efficiency and Organization in Electrical Projects

Using wire harness wire in electrical projects offers substantial improvements in efficiency and organization, crucial for both small-scale and large-scale operations. According to a 2022 report by the Electrical Wire Association, projects that utilize wire harnessing techniques report a 30% reduction in installation time and labor costs. This efficiency is largely due to the pre-assembled nature of wire harnesses, which come ready to install, minimizing the time spent on layout and assembly. The reduced need for individual wire management also decreases the likelihood of errors during installation, leading to more reliable electrical connections.

Moreover, the organization of wires and components plays a vital role in maintaining project integrity. A report from the International Electrotechnical Commission highlights that organized wiring systems contribute to a 25% decrease in troubleshooting time. Efficient wire harnessing not only streamlines the overall design but also facilitates easier maintenance and upgrades in the future. When wires are bundled and labeled systematically, technicians can quickly identify and resolve issues, fostering a more productive work environment. Thus, incorporating wire harness wire in electrical projects significantly enhances both operational efficiency and organizational clarity.

Cost-Effectiveness of Wire Harness Solutions for Wiring Needs

When it comes to electrical projects, cost-effectiveness is often a key consideration. Utilizing

wire harness solutions can significantly reduce expenses associated with wiring needs.

Wire harnesses are

pre-assembled groups of wires that allow for streamlined installation, which not only saves on labor costs but also minimizes

the potential for errors during the wiring process. By opting for these solutions, you can avoid the costs associated with

rework or troubleshooting that often arise from poorly executed wiring.

Additionally, wire harnesses can enhance the overall manufacturing efficiency, allowing projects to be completed faster.

The standardized and compact design of wire harnesses reduces the amount of time spent on wiring logistics, as they are

easier to manage and connect. Furthermore, with reduced material waste and lower likelihood of damage during installation,

projects can experience added savings over time. From a long-term perspective, investing in wire harness solutions can

lead to substantial financial benefits while ensuring reliability in your electrical systems.

Versatility of Wire Harness Wire Across Different Industries

Wire harness wire is a crucial component in various industries, demonstrating remarkable versatility across different applications. In the automotive industry, for instance, wire harnesses are integral for connecting components such as sensors, lights, and entertainment systems, ensuring seamless communication between parts. The adaptability of wire harness wire allows it to withstand diverse environmental conditions, making it suitable for vehicles that operate in extreme temperatures and humid conditions. Its insulation properties protect against wear and tear, enhancing the longevity and reliability of automotive electrical systems.

In the telecommunications sector, wire harness wire plays a vital role in transmitting data efficiently. It facilitates connections between devices, such as routers and servers, providing a stable and secure medium for communication. The flexibility in design allows engineers to create customized wiring solutions that fit specific needs, optimizing performance and minimizing signal loss. Beyond automotive and telecommunications, wire harness wires find applications in industries like aerospace, medical electronics, and consumer electronics, showcasing their broad functionality. This versatility ensures that projects across sectors can benefit from the reliability and efficiency of wire harness wire.

Top 10 Benefits of Using Wire Harness Wire for Your Electrical Projects

Related Posts

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

Why Cable Wire Harness Assembly is Crucial for Your Product Success

-

How to Choose the Right Wire Harness Wire for Your Project

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

How to Successfully Navigate Wire Harness Manufacturing Processes and Challenges