Top 10 Harness Assembly Solutions: Boosting Efficiency with Industry-Leading Data and Insights

In the ever-evolving landscape of manufacturing and assembly processes, the importance of harness assembly solutions cannot be overstated. According to the latest report by MarketsandMarkets, the harness assembly market is projected to reach $14.5 billion by 2025, driven by the increasing demand for electronics and automotive components. As industries seek to enhance operational efficiency and reduce time-to-market, innovative harness assembly solutions are becoming crucial to sustain competitive advantage.

Industry expert Dr. Emily Tran, a leading figure in harness assembly technology, emphasizes this trend by stating, “The optimization of harness assembly processes can lead to significant reductions in production costs and time, allowing companies to adapt swiftly to market demands.” Her insight resonates with findings from the International Data Corporation, which revealed that organizations leveraging data-driven approaches in their assembly operations saw a 30% increase in efficiency.

With the top 10 harness assembly solutions set to revolutionize the industry, understanding these pivotal insights is essential for manufacturers aiming to thrive in 2025 and beyond. This report will delve into the leading solutions that not only heighten productivity but also align with the dynamic needs of the marketplace, showcasing the transformative potential of advanced data utilization in harness assembly operations.

Innovative Approaches to Harness Assembly Efficiency in 2025

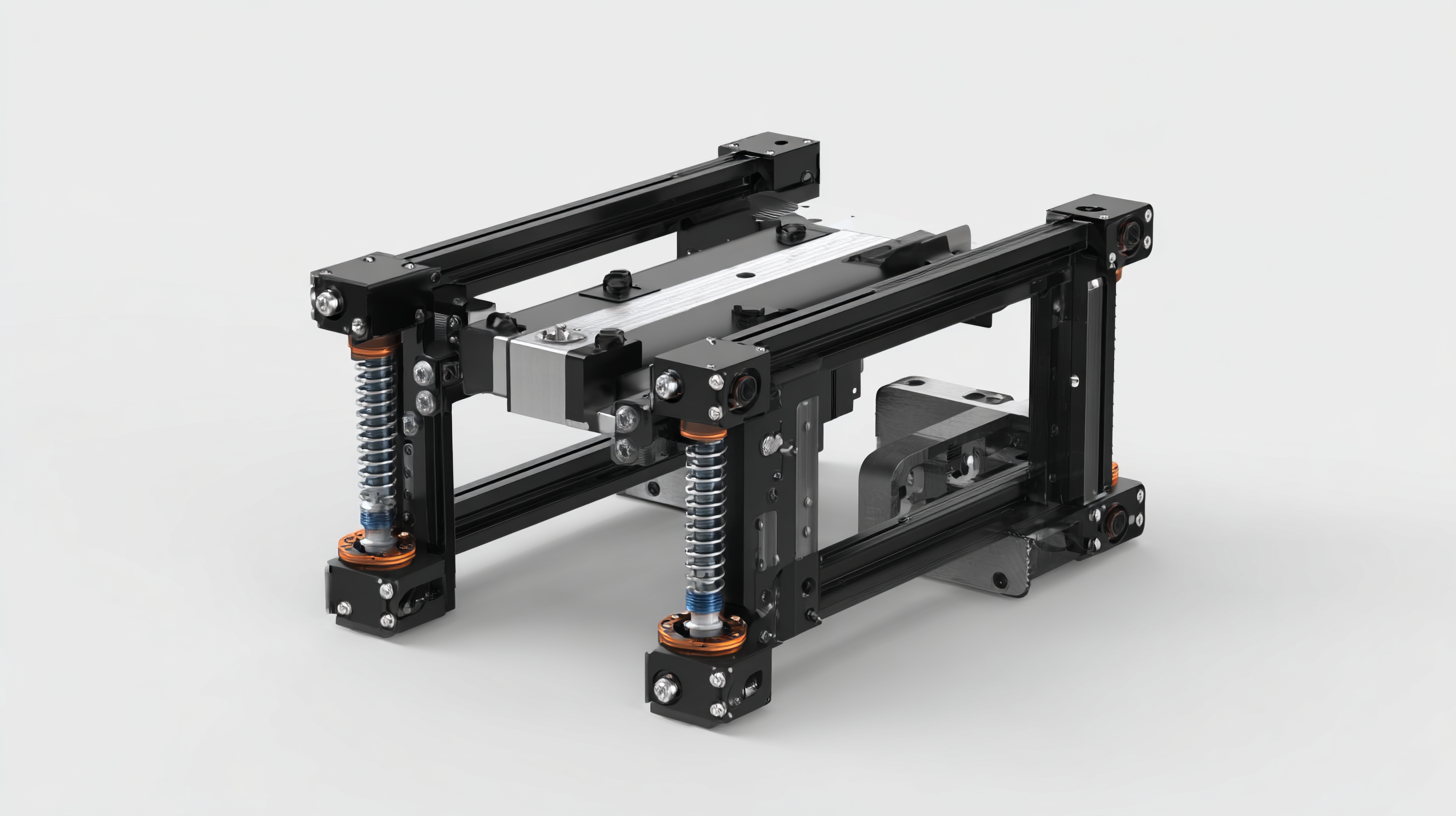

As we step into 2025, the landscape of harness assembly is witnessing remarkable transformations driven by innovative approaches aimed at enhancing efficiency. Modern technologies such as automated assembly systems, robotics, and artificial intelligence are revolutionizing traditional practices. These advancements enable manufacturers to streamline their processes, reduce assembly time, and minimize errors, ultimately leading to a more productive output.

Moreover, the integration of data analytics plays a pivotal role in optimizing harness assembly. By leveraging real-time data insights, companies can identify bottlenecks in their assembly lines and implement timely solutions. Predictive maintenance powered by data analysis also helps in preventing downtime, allowing for a smoother workflow. Emphasizing a proactive approach, organizations are not only improving their assembly efficiency but also ensuring a sustainable production environment by reducing waste and resource consumption. These innovative strategies are setting the stage for a new era in harness assembly, where efficiency and quality go hand in hand.

Key Industry Trends Influencing Harness Assembly Solutions

The evolution of harness assembly solutions is significantly influenced by key industry trends, particularly the integration of advanced technologies. One major trend is the rise of artificial intelligence (AI), which enhances operational efficiency and predictive capabilities in assembly processes. Companies are leveraging AI to analyze vast amounts of data, streamline workflows, and ultimately improve product quality and speed of delivery. The ability to predict trends and optimize decision-making has made AI an indispensable tool for manufacturers aiming to stay competitive in the rapidly changing market.

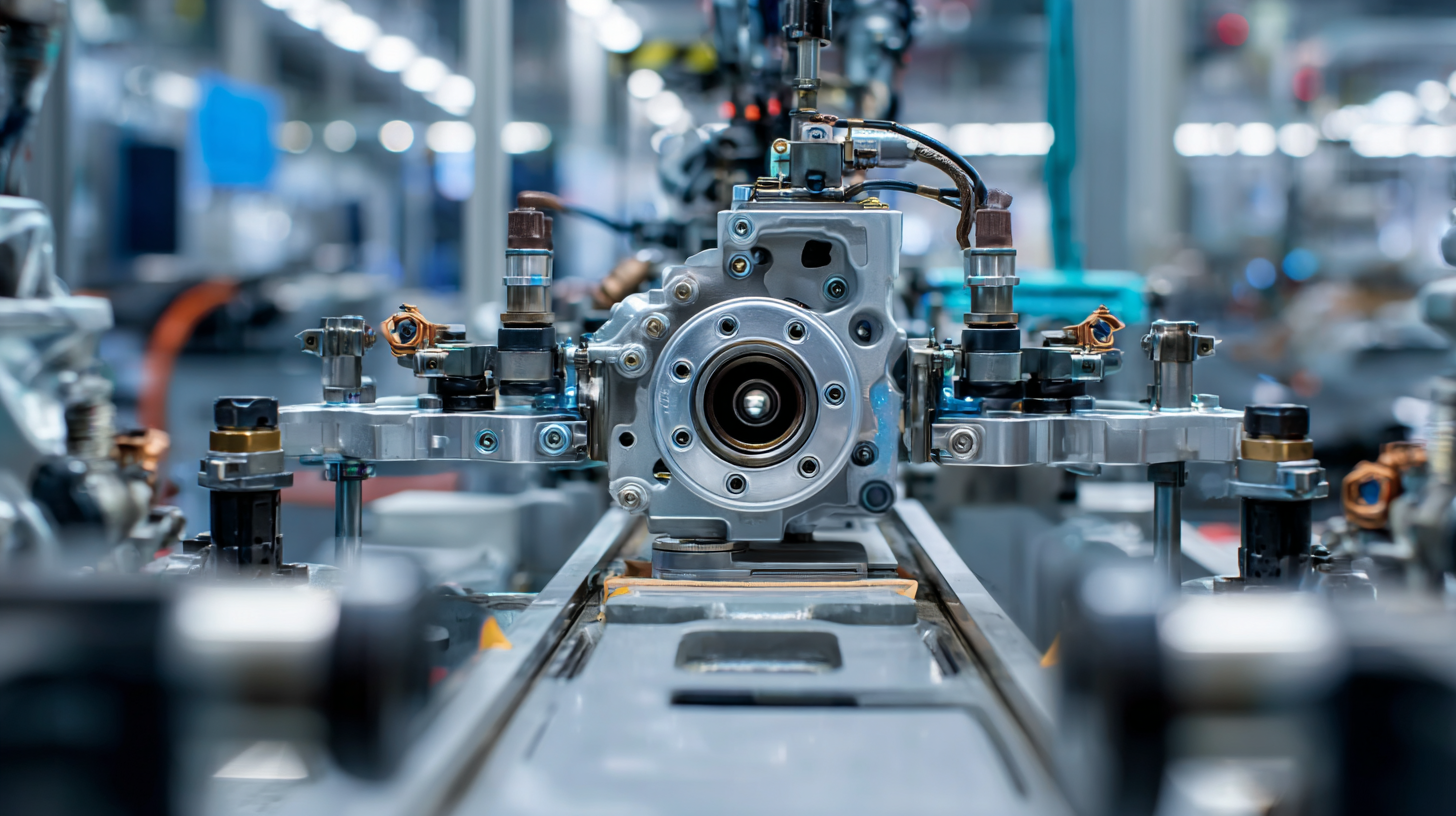

Additionally, the growth of electric vehicles (EVs) is reshaping the demand for wiring harnesses, as manufacturers must adapt to new specifications and technologies. The push for automation and smart manufacturing further drives innovation within the harness market, leading to more robust and efficient solutions. As businesses embrace these shifts, it is essential to remain informed and Agile.

Tips: To enhance your harness assembly processes, consider investing in AI tools that can analyze operational data. This investment can lead to smarter workflows and more informed decision-making. Additionally, staying updated on industry trends, such as the developments in EV technology, will enable you to pivot and adapt your strategies in alignment with market demands. Embrace change and foster a culture of innovation to remain competitive.

Top Technologies for Optimizing Harness Assembly Processes

The evolution of harness assembly processes is increasingly driven by cutting-edge technologies, which enhance efficiency and productivity across the manufacturing landscape. According to the 2025 Smart Manufacturing and Operations Survey, companies implementing smart factory strategies have reported up to a 30% increase in operational agility and a 25% boost in talent attraction. These advancements create an environment where businesses can uniformly adapt to market changes while minimizing production delays.

Harnessing artificial intelligence (AI) plays a crucial role in optimizing these processes. AI-powered automation solutions can analyze and streamline workflows, resulting in significant time savings and reduced labor costs. A report by industry analysts indicates that AI adoption in supply chains can lead to overall productivity improvements of up to 40%, allowing manufacturers to respond rapidly to supply chain disruptions and customer demands. As industries continue to evolve, the integration of advanced technologies in harness assembly will be vital to sustaining competitive advantage and driving economic growth.

Impact of Data Analytics on Harness Assembly Performance

The role of data analytics in improving harness assembly performance is increasingly critical in today’s manufacturing landscape. According to a recent report by McKinsey, companies that effectively leverage data analytics can see productivity improvements of up to 20%. This is particularly relevant in the harness assembly sector, where precision and efficiency are paramount. By utilizing advanced data analytics, organizations can optimize assembly line processes, identify inefficiencies, and reduce waste, ultimately leading to faster production cycles and lower operational costs.

Furthermore, a study conducted by Gartner highlights that companies utilizing predictive analytics in their assembly processes have reduced downtime by an astounding 30%. This capability allows manufacturers to anticipate equipment failures and proactively schedule maintenance, reducing interruptions in production. With the right data-driven insights, harness assembly operations can achieve a remarkable level of operational excellence, ensuring that high-quality products are delivered on time and within budget. The blend of data analytics and harness assembly not only enhances performance but also drives innovation, enabling organizations to stay competitive in a rapidly evolving industry.

Impact of Data Analytics on Harness Assembly Performance

Best Practices for Implementing Robust Harness Assembly Solutions

Implementing robust harness assembly solutions can significantly enhance efficiency in manufacturing processes.

One key practice is to standardize components and procedures.

By using consistent parts and defined workflows, teams can minimize errors and improve assembly speed.

Additionally, investing in high-quality tools and technologies can streamline operations, allowing workers to focus more on assembly and less on troubleshooting issues.

Tips:

Ensure that you conduct regular training sessions for your assembly team.

This keeps everyone updated on best practices and helps them become familiar with any new technologies.

Moreover, establish a feedback loop where team members can share insights on the assembly process.

This encourages continuous improvement and fosters a culture of collaboration.

Another best practice is to create a detailed documentation system for the harness assembly process.

Clear guidelines and visual aids help in maintaining quality standards and ensuring that all assembly tasks are performed correctly.

Regularly reviewing this documentation can lead to identifying potential areas for improvement and updating procedures based on real-time data.

Tips:

Utilize digital platforms for documentation to make it easily accessible and searchable.

Encourage team members to contribute to the documentation by sharing their experiences and suggestions,

which can lead to better practices being adopted across the board.

Related Posts

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

-

The Ultimate Guide to Choosing the Right Harness Builder for Your Industry Needs

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing