The Ultimate Guide to Rubber Air Hose Types in 2026?

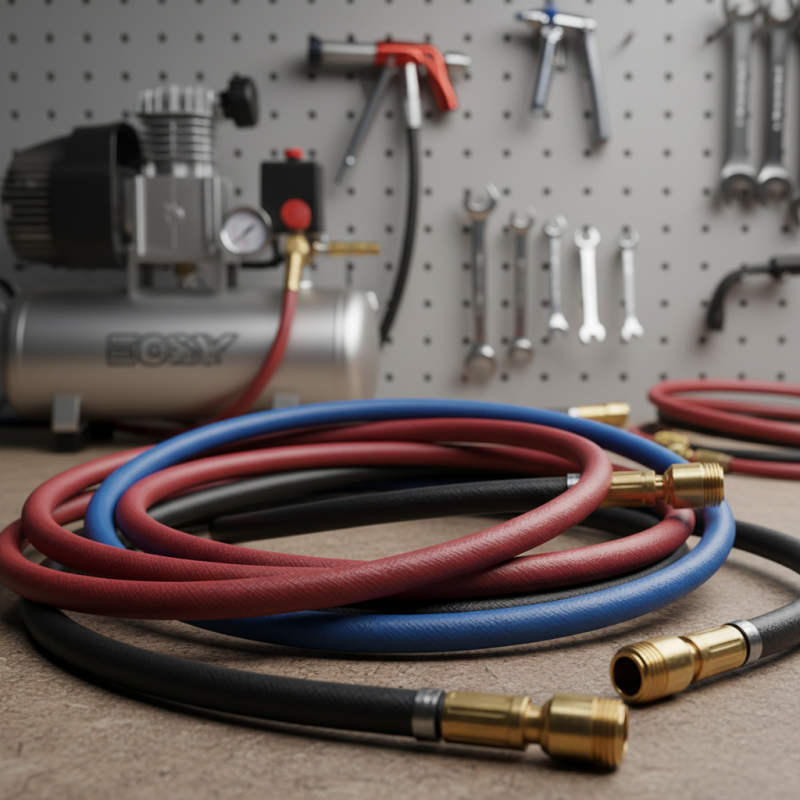

In the world of tools and equipment, the rubber air hose stands out as a crucial component. A reliable connection for air compressors, these hoses enable various applications. Whether for inflating tires or powering pneumatic tools, the right rubber air hose matters.

As we dive into the types available in 2026, one must consider the specific needs. Different environments require diverse features. For instance, some hoses offer flexibility in colder weather. Others withstand high pressures in demanding tasks.

Reflecting on past experiences, we notice a trend. Many users overlook the importance of quality. Choosing the wrong rubber air hose could lead to leaks or damage. It's essential to make informed decisions while considering different options.

Types of Rubber Air Hoses: A Comprehensive Overview for 2026

In 2026, rubber air hoses come in various types, each serving specific needs. One common type is the standard rubber hose, known for its durability and flexibility. These hoses can handle high pressure and are resistant to abrasions. They are ideal for outdoor use, but UV damage is a concern. Regular checks are essential to ensure longevity.

Specialty hoses have emerged as well. Reinforced hoses feature layers of synthetic materials, providing extra strength. They are great for industrial applications, but heavy-duty versions can be cumbersome. Lightweight options are popular among DIY enthusiasts. However, some users may find them less durable. It’s crucial to balance weight and strength when choosing.

The marketplace is dynamic, with innovations continually surfacing. New materials are being explored, aiming for improved performance. Some air hoses now boast increased flexibility in colder temperatures. Yet, not all innovations have proven effective. Users should remain cautious and well-informed before investing. Each hose type has advantages and drawbacks, making it vital to assess individual needs.

Key Specifications and Standards for Rubber Air Hoses in the Industry

When it comes to rubber air hoses, the industry has specific specifications and standards. Understanding these criteria is crucial for both consumers and manufacturers. Rubber air hoses vary in size, pressure ratings, and temperature resistance. These categories help users identify the right hose for their needs.

One important specification is the working pressure. It determines how much air the hose can handle safely. Many rubber air hoses are rated between 150 to 300 PSI. Another relevant factor is flexibility. Hoses must remain pliable, even in low temperatures. A stiff hose can lead to poor performance and even accidents in the workplace.

Standards also dictate how hoses are manufactured. The material used impacts quality and durability. Certain rubber compounds resist wear and tear better than others. Consumers often overlook these details when making a choice. Research is fundamental, but many skip it. Examining the standards can save money and enhance safety in the long run. Always ask questions and seek reliable information before purchasing.

Impact of Material Composition on Performance of Rubber Air Hoses

In 2026, the importance of rubber air hoses in various industries cannot be overstated. The material composition significantly affects performance, durability, and flexibility. Reports show that hoses made from higher-grade synthetic rubber can withstand extreme temperatures better than those from standard rubber. This allows them to perform consistently in demanding conditions.

Moreover, rubber air hoses exhibit different elastic properties depending on their formulation. For example, blending natural rubber with synthetic options enhances resistance to wear and tear. A recent industry study highlighted that hoses with a 30% synthetic blend had a 40% longer lifespan compared to those made entirely from natural rubber. While this data is promising, it's essential to consider factors like cost versus performance.

Some manufacturers may prioritize cheap materials, resulting in products that don't meet quality standards. This can lead to issues such as kinks and leaks, which compromise efficiency. Current trends indicate that companies focusing on premium rubber compounds may offer improved performance, but not every consumer is aware of this. Understanding these aspects of rubber air hoses becomes critical for making informed purchasing decisions in 2026 and beyond.

The Performance Comparison of Different Rubber Air Hose Types in 2026

Emerging Trends in Rubber Air Hose Technology and Innovation for 2026

The rubber air hose industry is evolving rapidly in 2026. New technologies are focusing on durability and flexibility. Advanced rubber compounds are making hoses lighter yet stronger. These innovations enhance performance in various applications. Users are now favoring hoses that offer excellent resistance to kinks and abrasion.

Tips: Always check for compatibility with your tools. Proper fitting ensures efficiency. A mismatched hose can lead to leaks or damage.

Emerging trends also emphasize sustainability. Recycled materials are becoming more common in production. This shift aligns with environmental initiatives. Companies are also investing in smart technology for enhanced monitoring. Sensors can track hose conditions and performance in real-time. While exciting, these innovations might introduce complexities in maintenance.

Tips: Regular inspections are crucial. Look for wear and tear. This step prevents sudden failures. Staying updated with new technology ensures optimal usage.

Market Analysis: Demand and Supply of Rubber Air Hoses in 2026

The demand for rubber air hoses is predicted to rise in 2026. Industries relying on compressed air, like construction and automotive, are expanding. This growing demand is driven by the need for durable and flexible hose solutions. Companies are now focusing on quality to meet rising standards. However, challenges loom ahead.

Supply chain issues continue to be a concern. The sourcing of raw materials can be inconsistent. As manufacturers ramp up production, they face pressure to balance quality and affordability. In some regions, logistical delays have impacted the timely delivery of rubber hoses. Companies must adapt their strategies to navigate these complexities.

Market analysis indicates a varied landscape. Some regions experience high demand, while others lag behind. Advances in technology may reshape the market dynamics. Innovation is crucial, yet not all companies are ready to pivot. There is room for improvement in embracing new materials. The industry must reflect on ways to enhance performance and address environmental concerns.