The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

In today's increasingly interconnected world, the role of cable harnesses has become pivotal in ensuring efficient and reliable electrical connectivity across various industries. According to a recent report by Research and Markets, the global cable harness market is projected to reach $90 billion by 2026, driven by the rising demand for automation and advanced technologies in automotive, aerospace, and electronics sectors. This substantial growth highlights the critical importance of choosing the right cable harness for your specific applications. Not only does a well-designed cable harness enhance the overall efficiency of your systems, but it also minimizes potential downtimes and maintenance costs. In this ultimate guide, we will delve into essential tips and considerations that can help you navigate the complexities of selecting the best cable harness to maximize efficiency and performance in your projects.

The Importance of Quality in Cable Harness Manufacturing for Global Markets

In the rapidly evolving global market, the quality of cable harness manufacturing has become a pivotal factor influencing not only product performance but also brand reputation. The intricate nature of these components means that even minor discrepancies in quality can lead to significant malfunctions or inefficiencies in electronic systems. High-quality cable harnesses are essential for ensuring reliable connectivity, reducing downtime, and enhancing overall operational efficiency across various industries, from automotive to aerospace.

Moreover, manufacturers must prioritize quality control throughout the production process, utilizing advanced materials and cutting-edge technologies to meet international standards. This commitment to excellence not only leads to better product performance but also fosters trust with consumers and stakeholders. As global competition intensifies, companies that invest in superior cable harness manufacturing practices will not only boost their market presence but also contribute to a more sustainable and innovative technological landscape. By recognizing the critical importance of quality, manufacturers can position themselves for long-term success in a demanding marketplace.

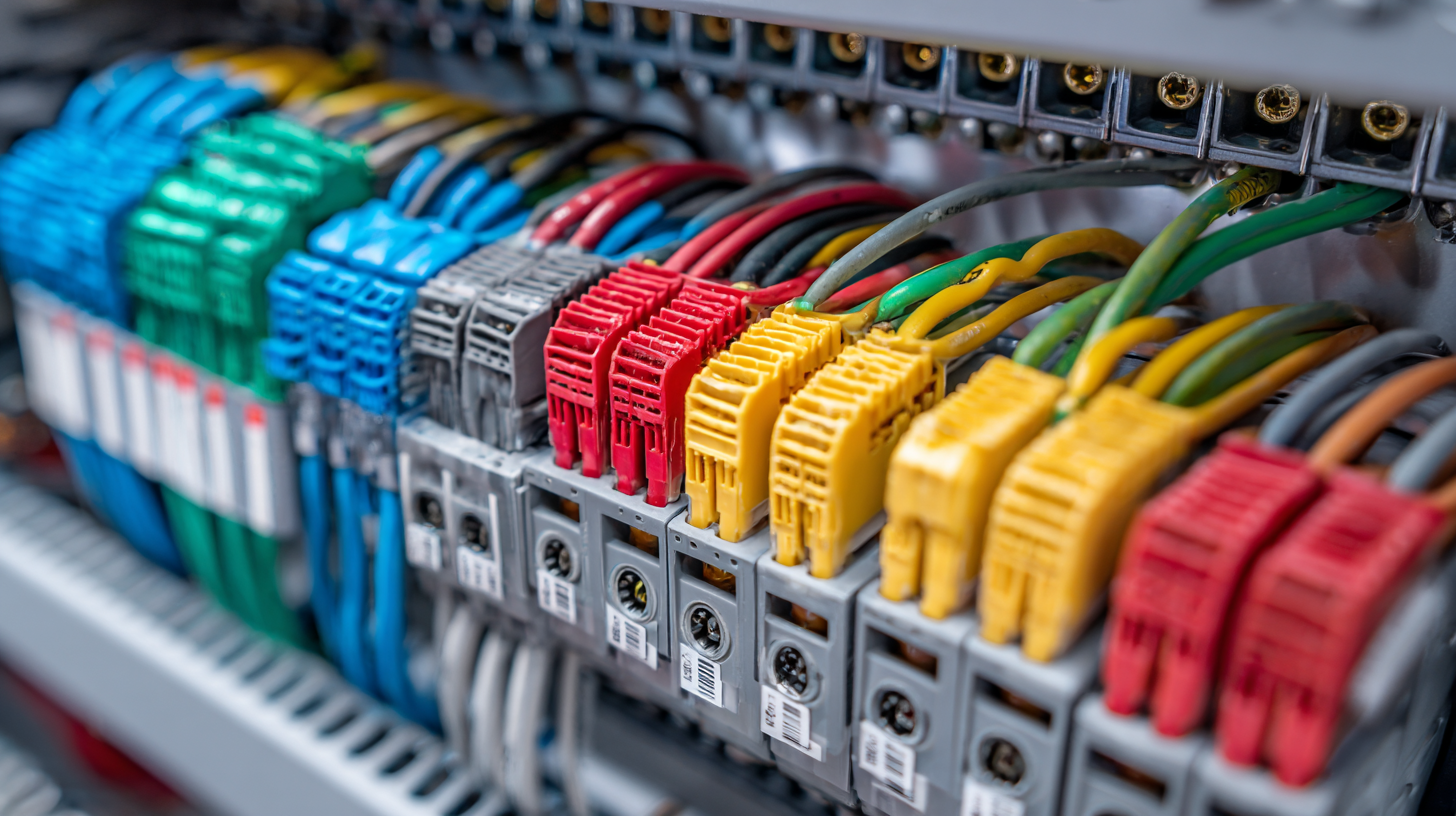

Key Factors in Selecting High-Performance Cable Harness Designs

When choosing a high-performance cable harness, several key factors must be considered to ensure maximum efficiency. According to a report by Allied Market Research, the global cable harness market is projected to reach $90 billion by 2025, driven by increasing demand across various sectors, including automotive and aerospace. This highlights the growing importance of selecting the right harness to meet specific application needs.

One critical factor to evaluate is the material composition of the cable harness. High-quality materials, such as thermoplastic elastomers and high-temperature PVC, provide better durability and flexibility, which are essential for performance in demanding environments. Additionally, cable harnesses designed with multi-layer shielding techniques can significantly reduce electromagnetic interference (EMI), enhancing signal integrity and reliability. As noted in a recent IEEE study, properly shielded harnesses can improve data transmission accuracy by up to 40%, a crucial advantage in high-tech applications.

Another vital aspect is the customization of the cable harness design. A tailored approach allows for optimization according to the specific layout and operational conditions of the machinery or vehicle. Research from the International Wire & Cable Symposium indicates that customized harnesses can lead to a 20% reduction in installation time and a decrease in potential failure rates. By focusing on these key factors, manufacturers can ensure that they select the most efficient cable harness for their projects.

Industry Trends: Innovations in Cable Harness for Enhanced Efficiency

In recent years, the cable harness industry has seen remarkable innovations that focus on enhancing efficiency across various sectors. According to a report by MarketsandMarkets, the cable assembly market is projected to reach $109.98 billion by 2025, driven largely by advancements in materials and manufacturing processes. These innovations include the use of lightweight, high-strength materials, as well as automation in production, which contribute to reduced lead times and improved performance.

Tips: When selecting a cable harness, consider materials like thermoplastic elastomers (TPE) for their durability and flexibility. This not only increases the lifespan of the harness but also reduces the overall weight, enhancing the efficiency of the application.

Another trend is the growing emphasis on eco-friendly manufacturing practices. A survey by IDTechEx highlights that over 40% of companies are shifting towards sustainable materials in their cable harness designs. This trend not only meets regulatory demands but also appeals to a more environmentally conscious consumer base.

Tips: Evaluate your supplier's sustainability practices and material certifications to ensure you’re making choices that align with industry standards and your corporate responsibility goals.

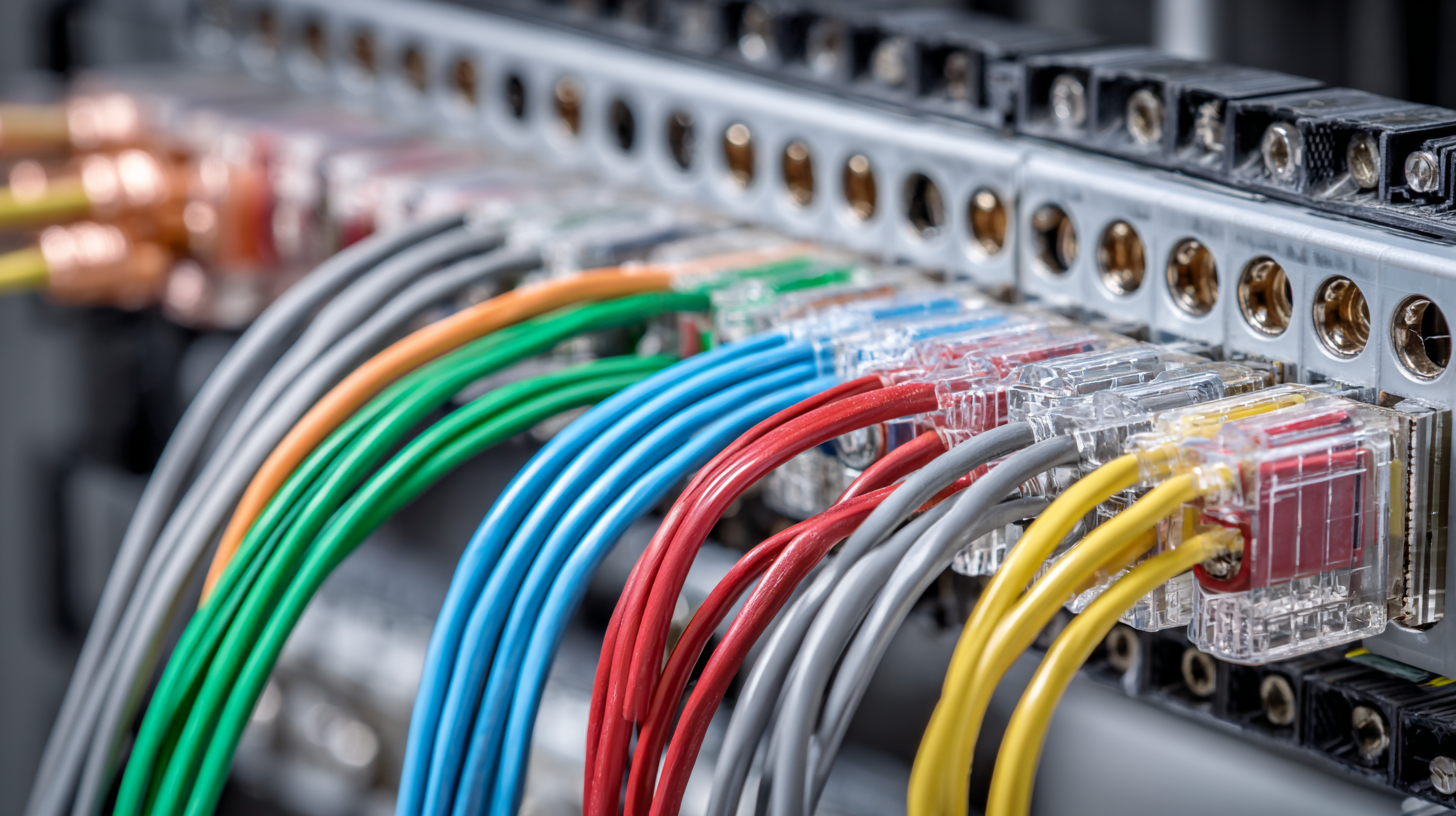

Understanding Material Specifications for Optimal Cable Harness Performance

When selecting a cable harness, understanding material specifications is crucial for ensuring optimal performance and efficiency. The choice of materials directly influences not only the durability but also the functionality of the harness. For instance, using high-quality insulated materials can significantly reduce the risk of short circuits, while robust outer sheathing provides resistance against environmental factors like humidity and extreme temperatures. Common materials such as PVC, polyurethane, and cross-linked polyethylene have their own unique advantages, making it essential to consider the specific application requirements when selecting the right material.

Moreover, the gauge of the wire plays a pivotal role in the performance of the cable harness. Thicker wires can handle higher currents, which is vital for applications involving heavy machinery or power distribution. On the other hand, lighter gauges may be more suitable for low-power applications where flexibility and weight savings are necessary. Additionally, understanding the temperature ratings and chemical resistance of materials can further refine the selection process, ensuring that the harness will maintain its integrity and performance under various operational conditions. By thoroughly evaluating these material specifications, you can optimize the overall efficiency of your cable harness for your specific applications.

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

This bar chart illustrates the performance metrics of different material specifications for cable harnesses, focusing on their tensile strength, flexibility, and thermal resistance. These metrics are crucial for ensuring optimal cable harness performance.

Cost Analysis: Balancing Quality and Affordability in Cable Harness Production

When selecting a cable harness, manufacturers must consider the intricate balance between quality and affordability, especially in light of a 2022 report by MarketsandMarkets which projected that the global cable harness market will reach $23.9 billion by 2025, growing at a CAGR of 7.7%. This growth is driven by the rising demand for durable and efficient cable solutions in various industries, including automotive, telecommunications, and renewable energy. As production costs rise, manufacturers are challenged to maintain high standards without compromising their competitive edge in pricing.

Cost-effective sourcing is pivotal in achieving this balance. According to a study from ResearchAndMarkets, over 40% of companies cite material costs as their largest expense in cable harness manufacturing. To address this, many manufacturers are exploring alternative materials and advanced manufacturing techniques, such as automation and lean production practices. By investing in these innovative approaches, companies can reduce waste and enhance productivity, ultimately lowering costs while still delivering high-performance cable harnesses that meet industry standards and customer expectations.

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

| Dimension | Value | Cost per Unit ($) | Material Quality Score (1-10) | Lead Time (days) |

|---|---|---|---|---|

| Standard Cable Harness | 1000 Units | 0.50 | 7 | 14 |

| High-Performance Cable Harness | 500 Units | 1.20 | 9 | 10 |

| Custom Cable Harness | 250 Units | 2.00 | 10 | 21 |

| Eco-Friendly Cable Harness | 800 Units | 0.75 | 8 | 15 |

| Industrial Cable Harness | 350 Units | 1.50 | 7 | 30 |