Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

The wire harness assembly is a critical component in various industries, serving as the backbone for electrical connectivity in vehicles, electronics, and machinery. According to a recent market analysis report by ResearchAndMarkets, the global wire harness market is projected to reach USD 70 billion by 2025, driven by advancements in electric and hybrid vehicles, as well as the growing demand for automation and smart technologies. Notably, countries like China have become leaders in manufacturing high-quality wire harness assemblies, showcasing their prowess in this essential domain.

This blog will delve into the unique features and applications of the best wire harness assemblies produced worldwide, emphasizing the innovation and quality that reflects China’s pride in global exports. By exploring the advancements and trends in wire harness assembly technology, we highlight its significance in addressing the needs of modern industries while ensuring safety, efficiency, and reliability.

The Significance of Wire Harness Assemblies in Modern Manufacturing

Wire harness assemblies play a crucial role in modern manufacturing, serving as the backbone of electrical distribution in numerous industries. According to a report by Research and Markets, the global wire harness market is projected to reach $226 billion by 2026, growing at a CAGR of 7.8% from 2019. This significant growth underscores the increasing reliance on wire harnesses for reliable electrical connections in applications ranging from automotive to aerospace, consumer electronics, and industrial machinery.

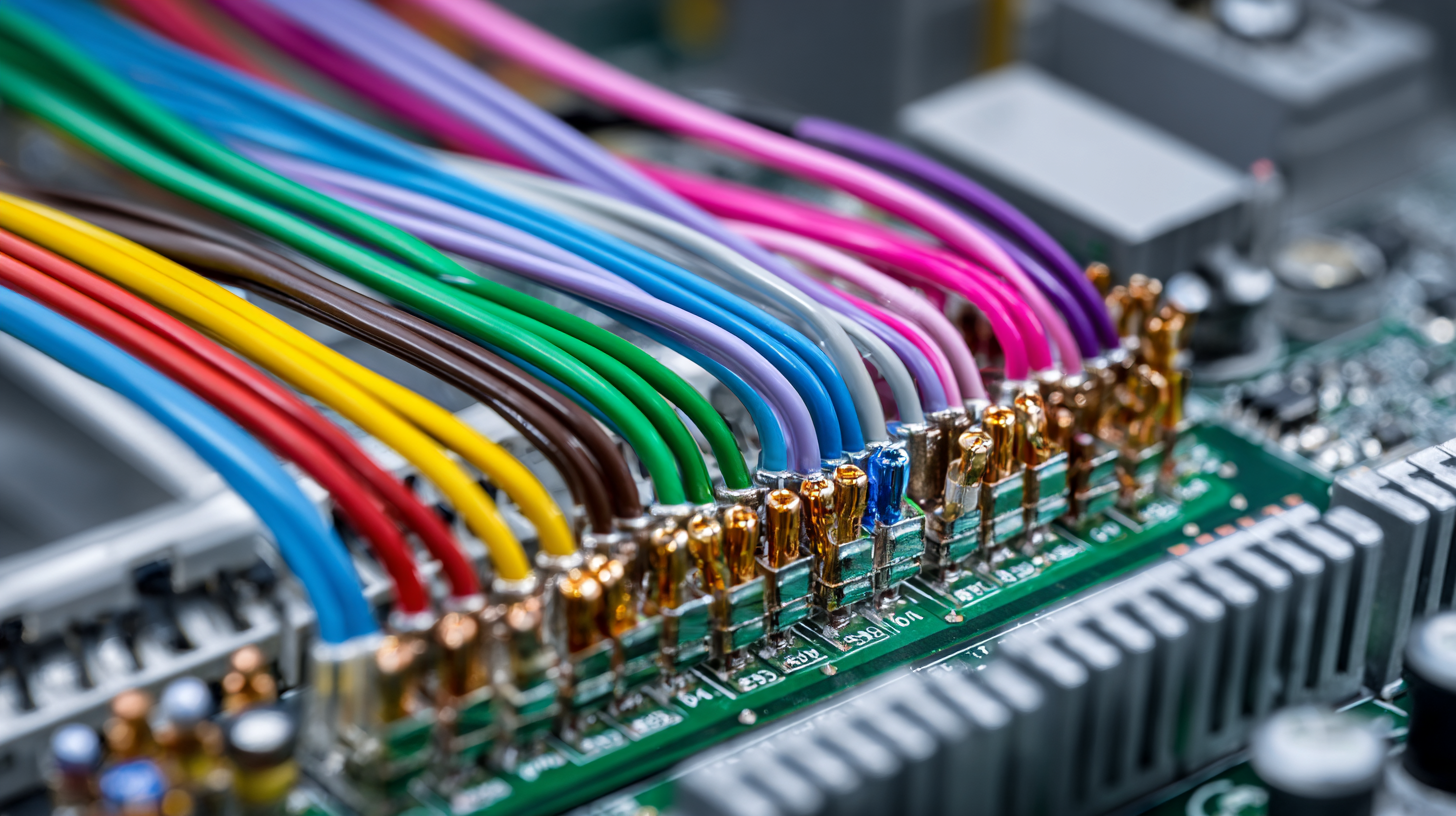

In addition to their essential function in facilitating electrical connectivity, wire harness assemblies contribute to improved efficiency and safety in manufacturing processes. A study by MarketsandMarkets highlights that the automotive industry alone utilizes over 3,000 electrical connections in a single vehicle, emphasizing the need for well-designed and durable wire harness assemblies. These components not only streamline assembly lines but also reduce the potential for errors, thereby enhancing overall product quality. As industries adopt advanced manufacturing technologies, such as automation and IoT, the demand for high-quality wire harnesses will continue to rise, reinforcing their significance in the ever-evolving landscape of modern manufacturing.

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

| Feature/Dimension | Description | Application Areas | Materials Used |

|---|---|---|---|

| Customization | Tailored to specific requirements of devices | Automotive, Aerospace, Industrial machinery | Copper, Aluminum, PVC, Polyethylene |

| Durability | Designed to withstand extreme environments and stress | Military, Marine, Heavy industry | Insulated wires, High-temperature materials |

| Complexity | Ability to integrate multiple functions and connections in one assembly | Consumer electronics, Medical devices | Multi-stranded wires, Shielding materials |

| Efficiency | Streamlined assembly process reducing installation time | Renewable energy systems, HVAC systems | Conductive materials, Heat-shrink tubing |

| Safety Features | Design ensures minimal risk of short circuits and overloading | Industrial automation, Robotics | Insulators, Circuit protection systems |

Key Characteristics that Define High-Quality Wire Harness Assemblies

High-quality wire harness assemblies are fundamental to the performance and reliability of various electrical systems across diverse industries. A key characteristic that defines these assemblies is their adherence to precise manufacturing standards, such as IPC/WHMA-A-620, which emphasizes the importance of proper materials, assembly techniques, and testing procedures. According to a report by Grand View Research, the global market for wire harness assemblies is expected to reach $57.54 billion by 2025, underlining their vital role in sectors such as automotive, aerospace, and consumer electronics.

Durability and resistance to environmental factors are also crucial attributes of top-notch wire harness assemblies. For instance, the use of heat-resistant and insulated materials can enhance longevity and reduce maintenance costs. The latest industry insights reveal that approximately 30% of failures in electrical systems can be attributed to poor wiring, making the choice of wire harness components critical to ensuring operational efficiency and safety. Furthermore, the integration of advanced technologies like automated manufacturing processes and real-time quality monitoring systems is increasingly becoming standard practice, driving improvements in precision and reducing production errors.

Innovative Applications of Wire Harnesses in Various Industries

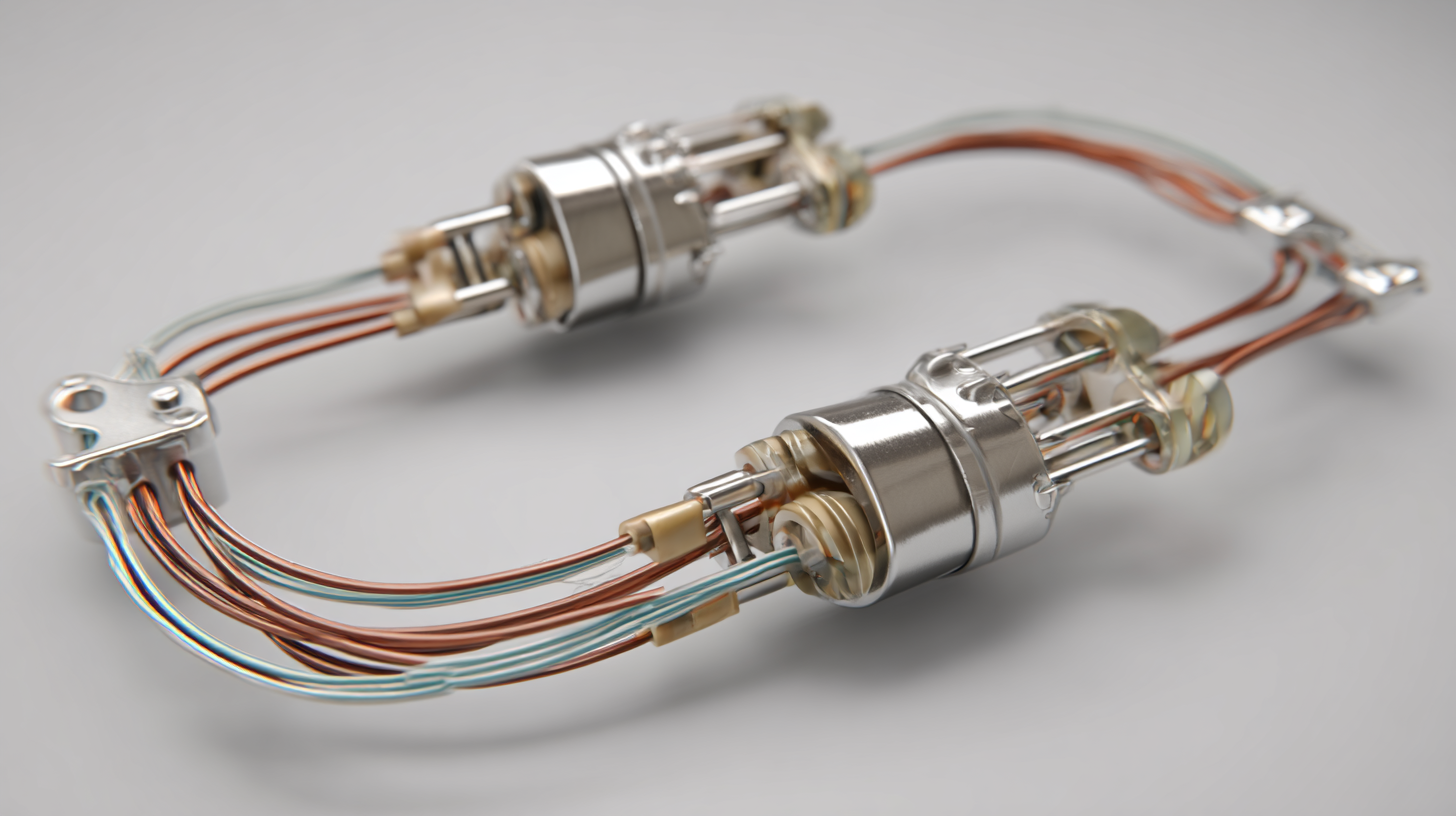

Wire harnesses play a critical role across diverse industries, showcasing their innovative applications and enhancing operational efficiency. In automotive manufacturing, wire harnesses are indispensable for managing the intricate electrical systems of vehicles. They ensure reliable connections between various components, from headlights to infotainment systems, ultimately contributing to vehicle safety and performance. Moreover, the rise of electric vehicles has necessitated advanced wire harness designs to support increased power demands and control strategies, driving innovation in this sector.

In the aerospace industry, wire harness assemblies are engineered to meet stringent safety and durability standards. They connect instruments, sensors, and communication systems in aircraft, ensuring seamless operation in challenging environments. Additionally, medical device manufacturing has also embraced wire harness technology, where precision and reliability are paramount. These specialized assemblies facilitate connections that power diagnostic equipment and other critical systems, underscoring the versatility of wire harnesses in meeting the unique demands of various fields. As industries continue to evolve, wire harnesses will remain at the forefront of technological advancement, adapting to new challenges and applications.

Applications of Wire Harnesses in Various Industries

China's Leading Role in Wire Harness Manufacturing for Global Markets

China has cemented its position as a global leader in wire harness manufacturing, catering to diverse industries such as automotive, aerospace, and consumer electronics. According to industry reports, China's wire harness market is projected to reach over $40 billion by 2025, driven by increasing demand for electric vehicles and advanced electronic systems. The country benefits from a robust supply chain ecosystem, which includes a vast network of suppliers and manufacturers, allowing for efficient production and cost-effective solutions.

China has cemented its position as a global leader in wire harness manufacturing, catering to diverse industries such as automotive, aerospace, and consumer electronics. According to industry reports, China's wire harness market is projected to reach over $40 billion by 2025, driven by increasing demand for electric vehicles and advanced electronic systems. The country benefits from a robust supply chain ecosystem, which includes a vast network of suppliers and manufacturers, allowing for efficient production and cost-effective solutions.

Moreover, China's advancements in technology and automation have enhanced the quality and precision of wire harness assemblies. With a workforce that is both skilled and adaptable, manufacturers in China are able to meet the evolving needs of global markets. A recent report highlighted that over 60% of the world's wire harness exports originate from China, underscoring its pivotal role in meeting the demands of international clients. As global industries continue to lean towards electrification and smart technologies, China's wire harness sector is poised for significant growth and innovation, further solidifying its leadership position on the world stage.

Future Trends and Technologies in Wire Harness Assembly Production

The rapid evolution of automotive technology is significantly reshaping the landscape of wire harness assembly, especially in the context of electric and smart vehicles.

With the growing complexity of electrical architectures, driven by advanced features such as active safety systems, infotainment, and connectivity services, the demand for sophisticated wire harness solutions has never been greater. This complexity necessitates innovative designs and manufacturing processes that adapt to the unique requirements of modern automobiles.

Current trends indicate a shift towards modular connectors and flexible circuit technologies, which streamline assembly processes while reducing weight and optimizing space within vehicles. As manufacturers aim to enhance efficiency and sustainability, the integration of wireless systems to minimize physical connections is emerging as a viable alternative.

Such advancements not only highlight the innovative direction of the wire harness industry but also underscore the critical intersection of technology and automotive design, paving the way for smarter, more efficient mobility solutions in the near future.